High Pressure Resin Transfer Molding (HP-RTM Mold) is a cutting-edge manufacturing process that has revolutionized the production of high-performance thermosetting composite parts. This technology combines the precision and efficiency of injection molding with the versatility and strength of composite materials, making it ideal for industries that demand both quality and speed. In this blog, we will explore the HP-RTM Molds process, its innovations, and its applications across various industries

Table of Contents

Toggle

Process Flow of HP-RTM Molds

- Preform Preparation:

- Fiber Unwinding and Cutting: Carbon fiber fabric is unwound and cut into preform layers using an automatic cutting machine.

- Preform Coating: The cut fiber fabric is coated with a pre-setting agent to enhance bonding and structural integrity.

- Layer Positioning and Stacking: The coated fiber fabric is positioned and stacked according to the designed fiber layer structure.

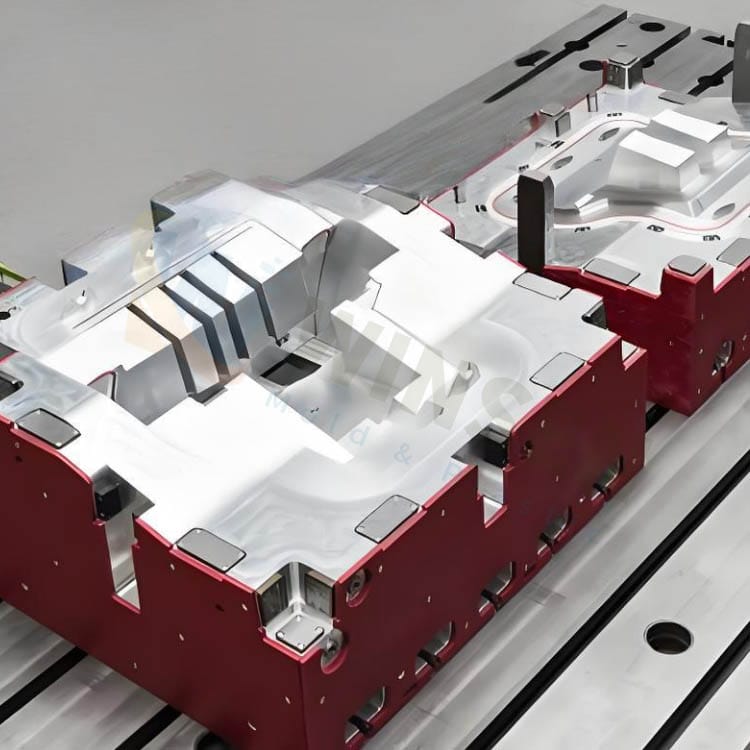

- Resin Transfer Injection:

- Vacuum Sealing and Resin Injection: The mold is vacuum-sealed, and low-viscosity resin is injected under high pressure into the mold cavity.

- Resin Curing: The resin is cured under high temperature and pressure, ensuring complete impregnation and solidification.

- In-Mold Spraying:

- Surface Coating: After resin curing, a low-viscosity mold surface resin is sprayed to enhance the surface finish.

- Demolding and Cleaning:

- Part Ejection: The molded part is ejected using a mechanical arm, and the mold is cleaned to remove any residual resin.

- Cooling and Shaping:

- Part Cooling: The molded parts are cooled and shaped using specialized tooling to ensure dimensional accuracy

Innovations in HP-RTM Mould Technology

- High-Precision Resin Metering and Mixing:

- HP-RTM technology relies on high-precision metering and mixing systems to ensure uniform resin distribution and rapid curing.

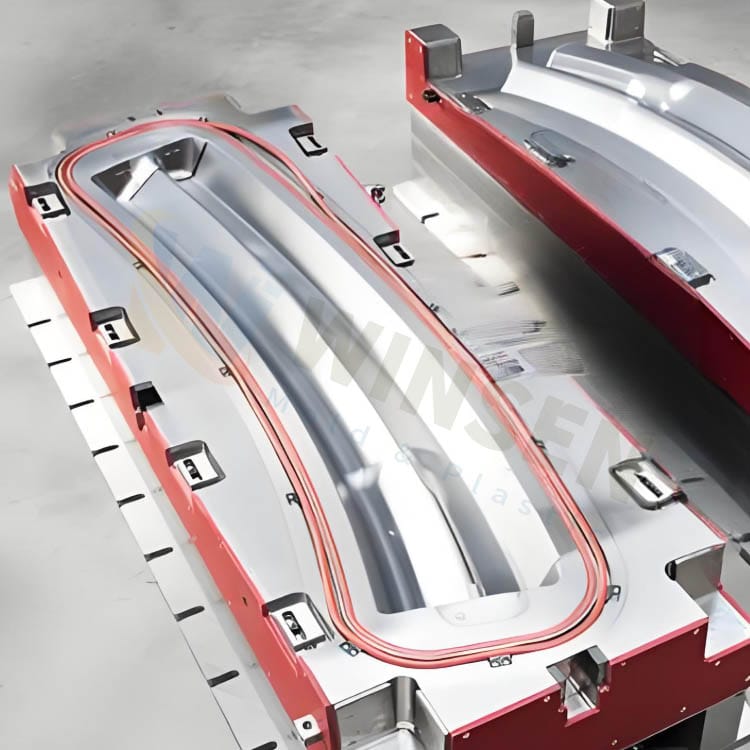

- Uniform Temperature Field Design:

- The design of the molding mold ensures uniform temperature distribution, which is crucial for consistent resin flow and fiber impregnation.

- Gap Injection and Post-Injection Compression:

- These techniques improve resin flow and reduce the risk of process defects, enhancing the overall quality and repeatability of the proces

Industry Applications

- Automotive Industry

- HP-RTM is widely used in the automotive sector for manufacturing high-strength, lightweight components such as body panels, structural frames, and interior parts.

- Aerospace Industry

- The aerospace industry benefits from HP-RTM’s ability to produce complex, high-strength composite parts with minimal defects, making it ideal for aircraft components.

- Renewable Energy

- In the renewable energy sector, HP-RTM is used to manufacture wind turbine blades and other components that require high strength and durability.

- Consumer Goods

- HP-RTM is also used in the production of consumer goods, such as high-end sporting equipment and luxury goods, where quality and performance are paramount

Cost-Effectiveness of RTM Moulds

- Mold Cost: While HP-RTM molds require a higher initial investment, their durability and high production efficiency can significantly reduce unit costs in large-scale production.

- Material Cost: While the high-performance resins and fibers used in HP-RTM are more expensive, their lightweight and high-strength properties can reduce material usage, thereby lowering overall costs.

- Production Efficiency: HP-RTM’s rapid curing and high production efficiency can shorten production cycles, increase output, and further reduce costs.

Production Efficiency of RTM Molds

- Rapid Prototyping: HP-RTM technology enables resin injection and curing in a shorter time, significantly improving production efficiency.

- Automation: HP-RTM technology can be integrated into automated production lines, reducing manual intervention and improving production consistency and efficiency.

- Mold Life: High-quality mold design and material selection can extend mold life, reduce mold replacement frequency, and improve production efficiency.

High-pressure resin transfer molding (HP-RTM) Mould technology has been widely used in many industries due to its high efficiency and high-quality production characteristics. Through technological innovation and process optimization, HP-RTM is expected to further promote the lightweight and high-performance development of composite materials in the future and meet the needs of various industries for high-performance and lightweight components.

Conclusion

HP-RTM technology represents a significant advancement in composite manufacturing, offering a combination of precision, efficiency, and quality that is unmatched by traditional methods. Its applications span across multiple industries, from automotive and aerospace to renewable energy and consumer goods, demonstrating its versatility and potential for future growth. As technology continues to evolve, HP-RTM is poised to play an even more critical role in the production of high-performance composite parts