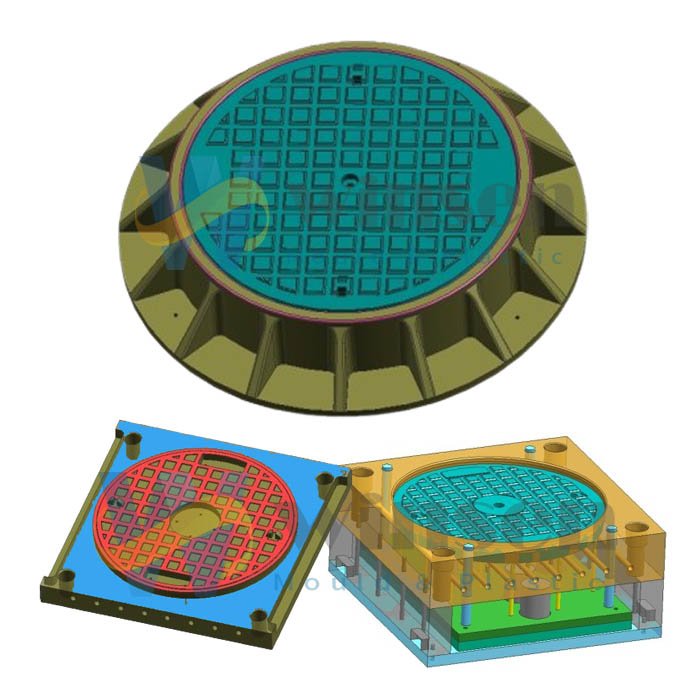

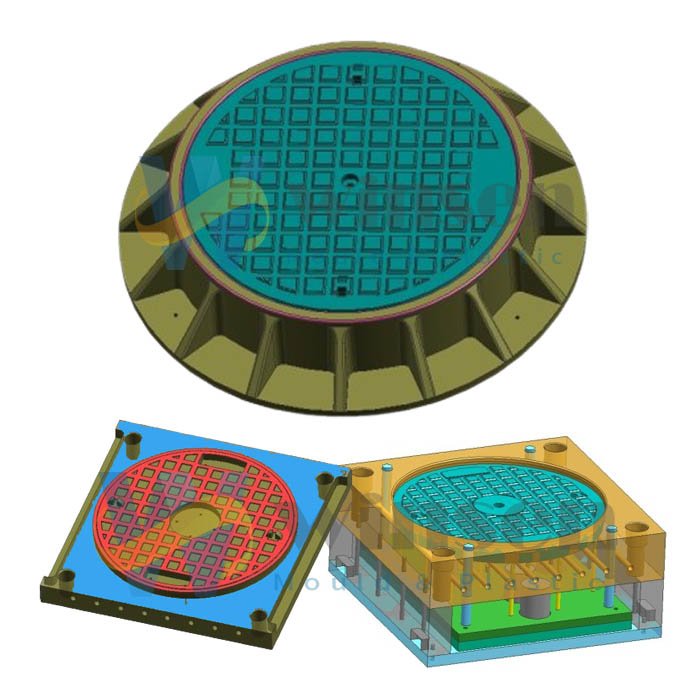

SMC BMC Manhole Cover Mold

Professional manufacturer of fiberglass(FRP) composite compression manhole cover mold

SMC BMC Composites Material Compression Manhole Cover Mold Maker

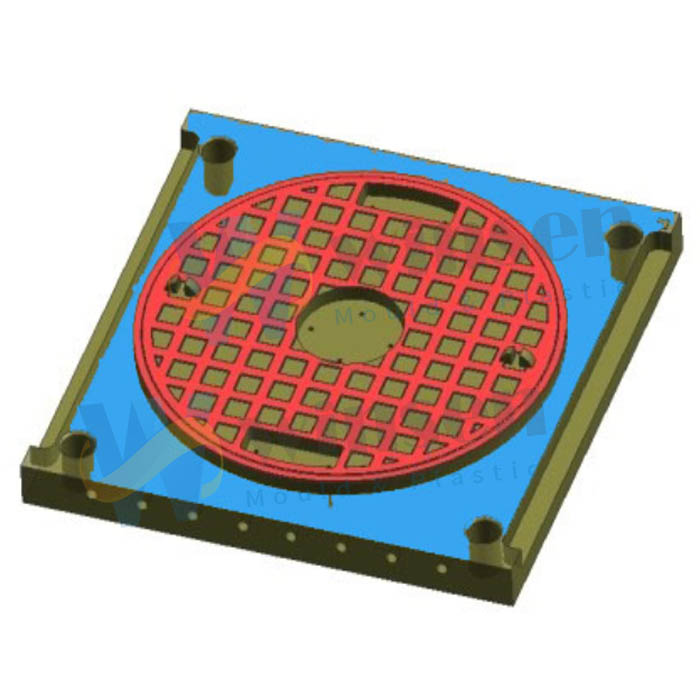

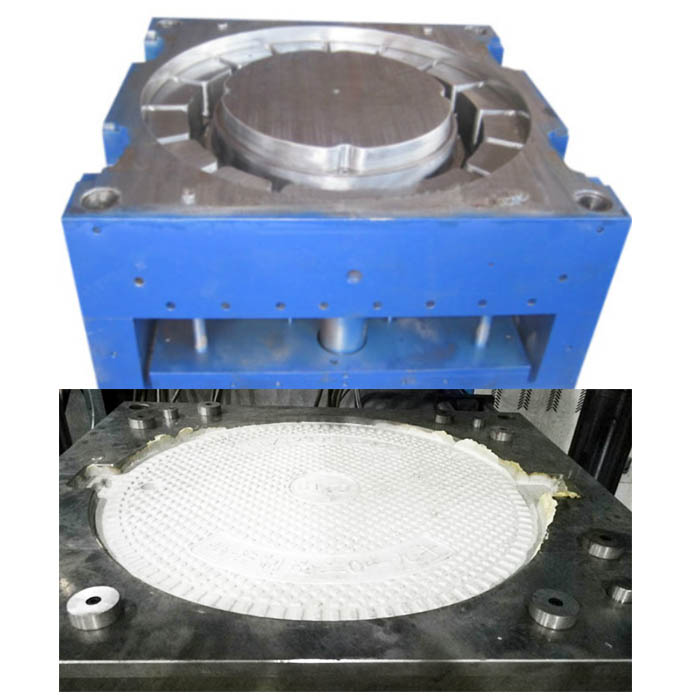

WS MOLD specializes in the production of composite material SMC BMC FRP GRP manhole cover molds,there has round and square manhole cover mould. The company’s molds are made of high-strength materials. The hardness of the materials generally exceeds HRC45, and the quality is excellent. At the same time, high-speed CNC machining centers are used to process all kinds of manhole cover mold, and the Sewage Manhole Cover Mold and Electric Telecom Manhole Cover mold accuracy is guaranteed.

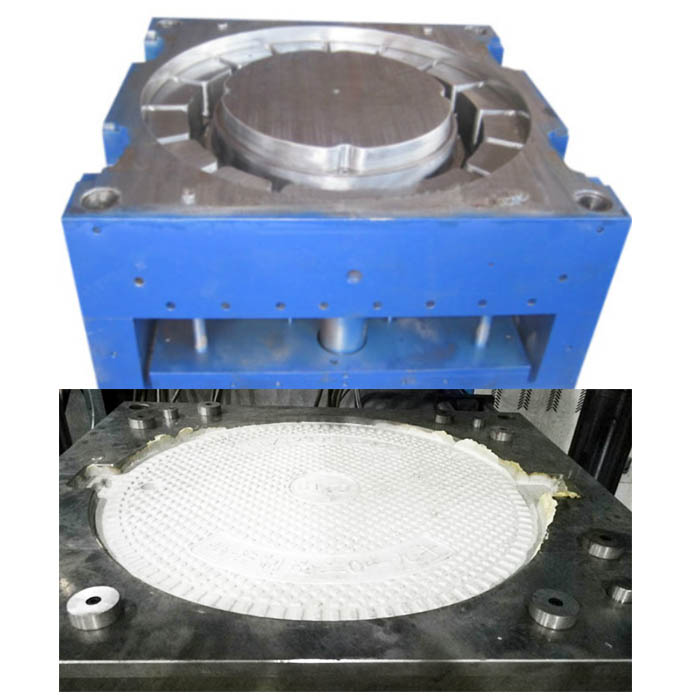

SMC Manhole Cover Mold

The preferred manufacturer of SMC manhole cover mold, focusing on the composite material manhole cover mold industry for many years, with strong technical strength and excellent product quality, WS manhole cover mold factory looks forward to cooperating with you!

BMC Manhole Cover Mold

WS is specialized company dedicated to the design and manufacture of BMC Manhole Cover Mold. Now it is mainly engaged in providing manufacturing and processing services of manhole Cover Mold for various municipal enterprises and manhole cover production industries

Fiberglass Manhole Cover Mold

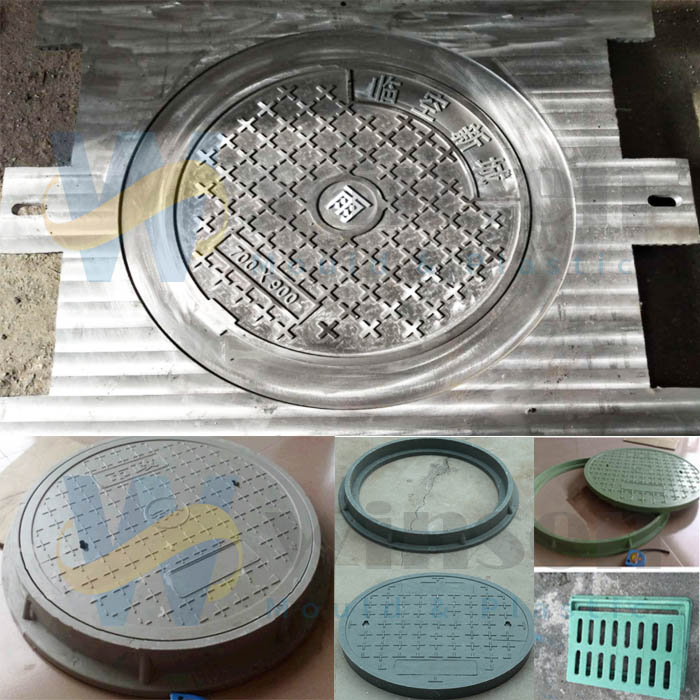

Fiberglass Manhole Cover Mold is used to produce fiber glass Manhole Cover,it is fiber glass material with compression molding molds produced by four-column Hydraulic press, which is used to cover roads or deep wells in homes to prevent people or objects from falling.

FRP GRP Manhole Cover

FRP GRP Manhole Cover Mold developed by WS, the FRP GRP Manhole Cover produced by our mold has the characteristics of light weight, high strength, high temperature resistance and excellent anti-aging performance. Subway, urban construction, tunnel, etc.

Compression Manhole Cover Mold

Which is the best Compression Manhole Cover Mold ? Look for WS mold to focus on the production of cable polymer resin Compression Manhole Cover Mold, factory direct sales.Our manhole cover mold can customize the LOGO as an interchangeable insert

Composite Manhole Cover Mold

WS Mold is mainly engaged in composite material molding molds, especially experienced in the production of composite Manhole Cover Mould. It integrates design, R&D, production and sales. The mold investment is small and can quickly recover the investment

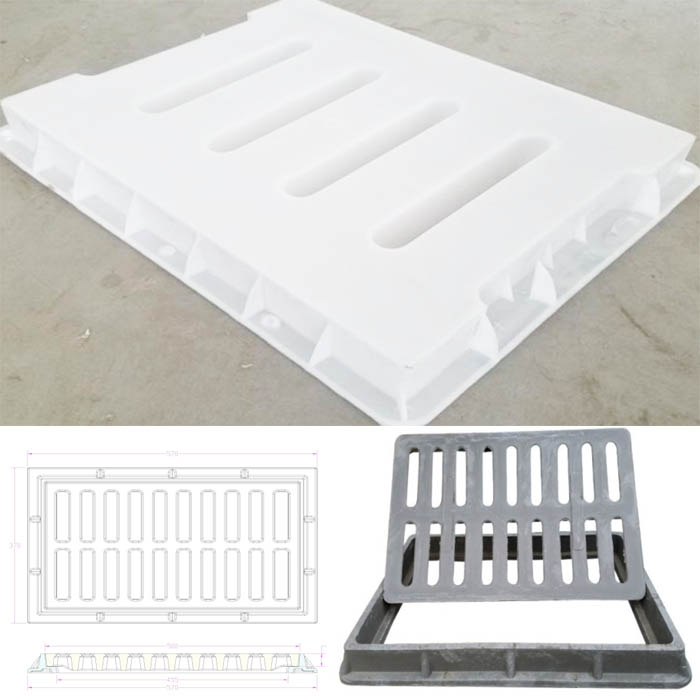

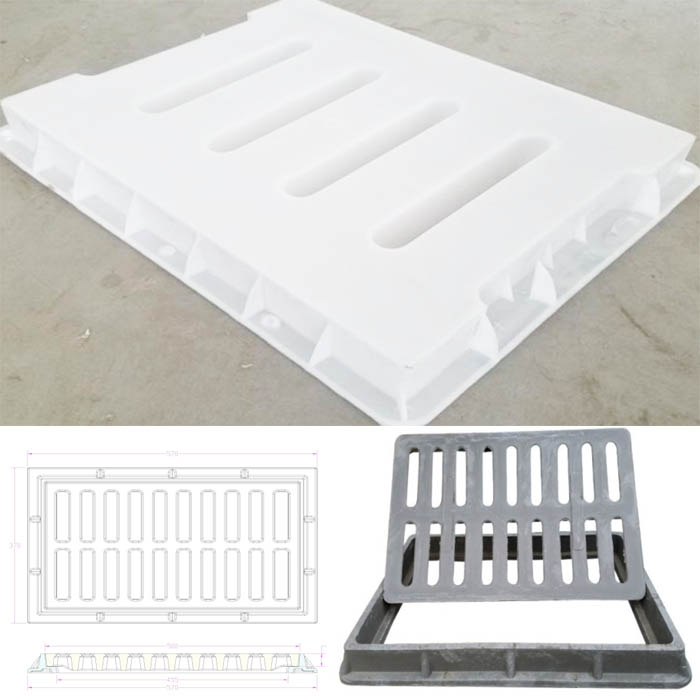

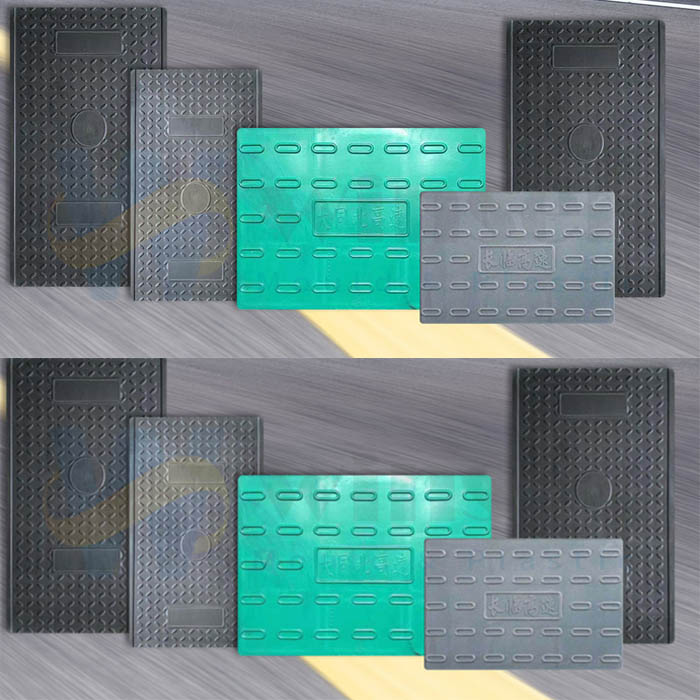

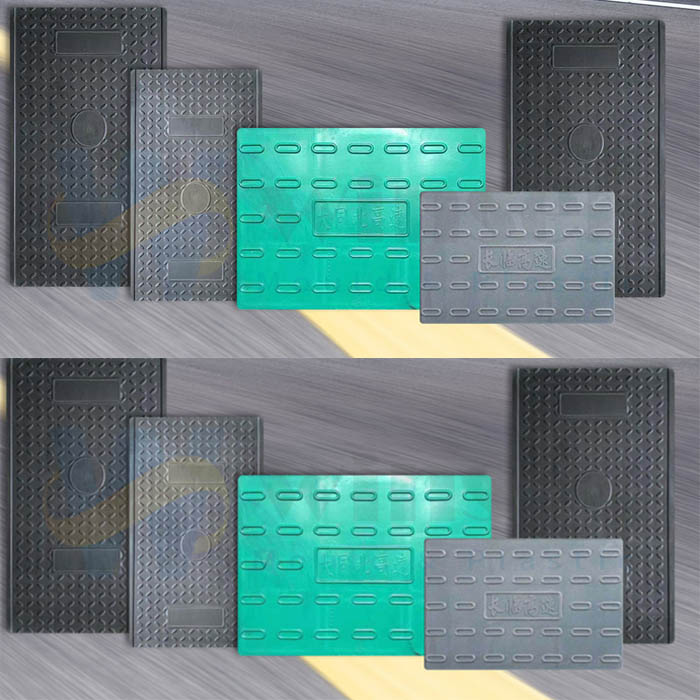

Polymer Resin Compression Mold Rectangle Cable Trench Cover Plate Mould

Rectangle Cable Trench Cover Plate mould is widely used in our daily life, and has become the focus of future development. The mould can be designed and customized according to customer needs, so that the product can better meet customer requirements and better meet the market.

SMC Sheet Molding Compound Cable Trench Cover Mold Compression Mould

Our company specializes in the production of SMC Sheet Molding Compound manhole cover mold, strict production process, stable product quality.Which is the best cable trench cover mold? Look for WS mold to focus on the production of cable polymer resin composite cover molds, factory sales.

The rainwater drainage manhole cover mold has the advantages of strong toughness, high brightness, no deformation, easy demoulding, and low breakage rate. This manhole cover mold can be used to produce various tap water manhole covers, sewage manhole covers, rainwater manhole covers with diameters of 60, 70, and 80. , manhole covers, etc., which are widely used and are the most popular mold products on the market.

SMC BMC FRP Composites Manhole Cover Mold

Sheet Molding Compound Mahole Cover Mold

Contact Us Now For Your SMC Sheet Molding Compound Manhole Cover Mold Solution

Find the reliable supplier for your square and round sewer manhole Cover mold and frame mould , we can suply all kinds of model and specification composite compression manhole cover molds,The compression molding Bulk Molding Compound manhole cover mould custom production with export high quality

Manhole Cover Mold Design

Sheet Molding Compound(SMC) Manhole Cover Mold

Bulk Molding Compound(BMC) manhole cover mould

Fiberglass(FRP GRP) Reinforced Plastic Manhole Cover Mould

Features of SMC BMC Composite manhole cover molds we produced

1. High strength: magnesite inspection, with high compressive, bending and impact strength, and toughness. After long-term use, the manhole cover will not be crushed and damaged, which can completely prevent the occurrence of “urban black hole” accidents.

2. Beautiful appearance: The surface pattern of magnesite inspection manhole cover is exquisitely designed, the color is bright and adjustable, and the urban environment is beautified.

3. Easy to use and light weight: the weight of the product is only about one-third of that of cast iron, which is convenient for transportation, installation and emergency repair, and greatly reduces labor intensity.

4. Anti-theft: magnesite inspection manhole cover has no recycling value, and is naturally anti-theft; according to customer needs, it is equipped with a locking structure to achieve anti-theft of property in the well.

5. Strong weather resistance: The magnesite inspection manhole cover can be used normally in the environment of -50℃~+300℃ through scientific formula, advanced technology and perfect technical equipment.

6. Acid and alkali resistance,corrosion resistance,wear resistance,vehicle rolling resistance,long service life.

It can be customized according to your needs, and the models and specifications of the molds are various!

Years of production experience of manhole cover molding die, contact you for a quotation, and give you the most professional solution.

There are manhole covers on the roads of most cities in China, so the manhole cover mold industry is booming

Technical parameters of manhole cover

Technical parameters Test load: heavy 400KN, general 250KN, light 125KN

Bending Strength: Average 22MPa Impact Strength: Average 10J/m2

Water absorption rate: 1%

Acid resistance: sample at 20%

Soak in sulfuric acid solution for 48h

No corrosion on the surface, mass loss of 1

Fiberglass Reinforced Plastic Manhole Cover Compression Mold

SMC BMC FRP GRP Manhole Cover Mold Telecom Cover Mould

Conventional dimensions of manhole covers

1. 50-type manhole cover: the diameter of the upper cover is 500mm ,manhole cover mold edge thickness 40mm center thickness 80mm;

2. 60 light-duty manhole cover, the diameter of the upper cover is 600mm, the thickness of the edge is 50mm, and the thickness of the center is 100mm;

3. 60 heavy-duty manhole cover, the upper cover diameter is 600mm, the edge thickness is 50mm, the center thickness is 110mm;

4. 70 light-duty manhole cover, the upper cover diameter is 700mm, the edge thickness is 50mm, the center thickness is 100mm;

5. 70 heavy-duty manhole cover, the upper cover diameter is 700mm, the edge thickness is 60mm, the center thickness is 120mm;

6. Type 80 manhole cover, the upper cover diameter is 800mm, the edge thickness is 60mm, the center thickness is 150mm;

7. Horizontal manhole cover ,The length*width of the upper cover is 750*450mm, the edge thickness is 45mm, and the center thickness is 120mm;

8. Three-piece set of vertical water collecting well cover, the outer edge length is 800*width 600*height 350mm, and the thickness of the upper cover is 45mm

What are the advantages of manhole covers produced by WS cable trench cover molds

1. High bearing capacity and strength As a trench cover, the most important thing is to see the bearing capacity and strength of its board. In the past, the trench cover was made of cement, but with the development of science and technology, there are now composite materials. Ditch cover, their bearing capacity and strength are much stronger than cement boards.

2. Strong sealing ability In addition to a certain bearing capacity, the sealing performance of the cable trench cover is also very important. This is because the better the sealing performance, the better the protection ability of the cable, so the cable trench cover with good sealing performance is the right The best protection for the cable, so as not to cause damage to the cable.

The cable trench produced by cable trench cover mould compression mould plays an important role in the construction of urban drainage and is divided into two types: indoor and outdoor.

Composite Cable Trench Cover Plate Mold

SMC Manhole Cover compression mould

Classification of manhole covers

There has metal manhole covers, high-strength fiber cement concrete manhole covers, resin manhole covers, etc. Usually round can be used for green belts, sidewalks, motor vehicle lanes, alleys etc.

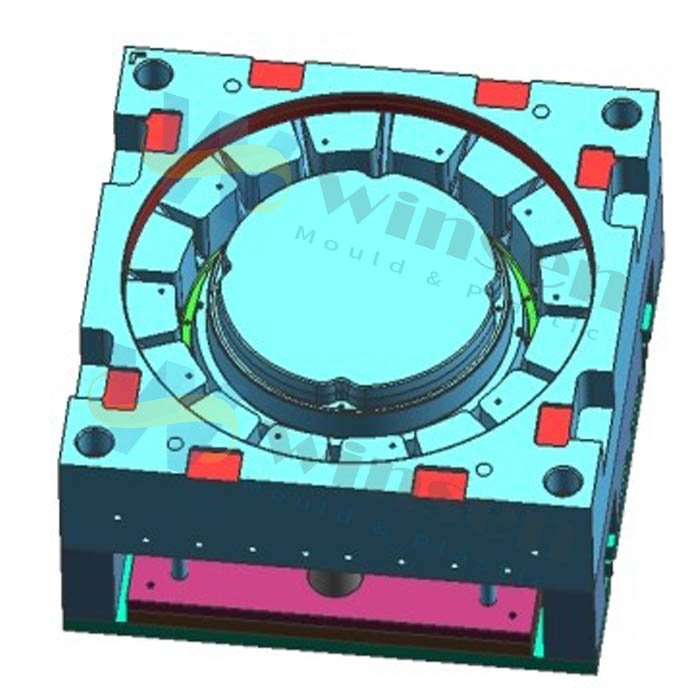

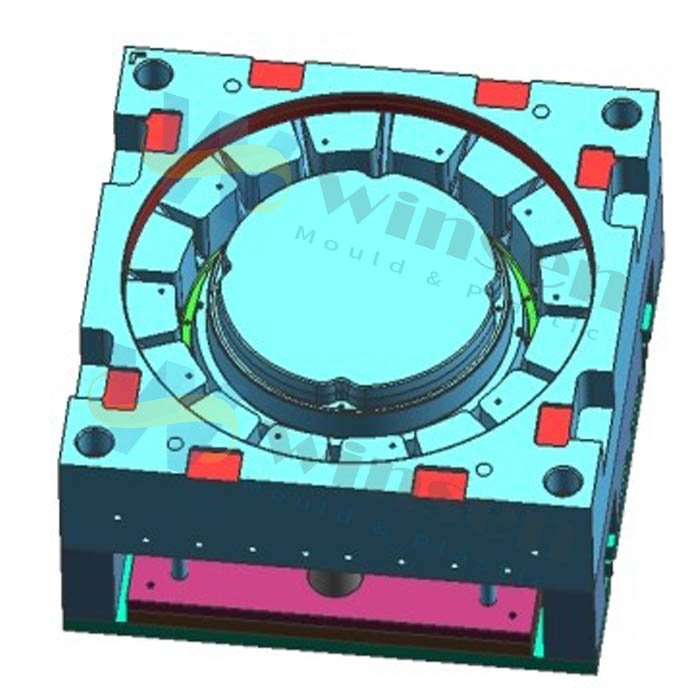

Manhole cover molds of material, design and production

SMC BMC FRP GRP compression manhole cover mold steel: Imported or domestic high-quality steels such as P20, 2738, 718, H13, NAK80, 2316, S136, etc. are used, and through reasonable heat treatment methods, the steel can achieve higher hardness and ensure the life of the mold.

Our compression mold structure designer and product stylist have rich experience in design work, and can analyze all aspects of mold structure and product structure (including: mold release slope, product surface microcosm, heating system design, exhaust system design, cooling system design, etc.)

Mold making time: small mold: 35-45 days; medium and large mold: 45-60 days.

For the production of manhole cover molds, we currently have various mold processing equipment, Mazak CNC lathes, high-speed injection molding machines, high-precision CNC grinding machines, CNC machining centers, slow wire walking and EDM equipment. At the same time, the company adopts computer CAD/CAM/CAE system (PRO/E, UG, etc.) for computer-aided design and processing software, and can independently undertake various types of difficult, high-precision large, medium and small molds from international high-end customers, and professionally research and develop various cover molds. And the design and processing of daily necessities molds, the product quality has won the recognition and appreciation of our customers.

WS has occupied the market with the business philosophy of “high quality, superiority, standard and standard”, and has been praised by the majority of users. Both the enterprise and the manhole cover mold and cable trench cover moud have become the benchmark in the industry.

WS is a professional manufacturer dedicated to moulding fiberglass manhole cover moulds. With nearly 20 years of experience in the industry and the courage to innovate, we have manufactured batches of high-quality, high-difficulty, high-efficiency, multi-cavity, and long-life compression molding dies for domestic and foreign customers.