Medical Device Products Molds

Professional manufacturing of Precision molds for medical laboratory consumables products

Taizhou Huangyan WS MOLD specializes in the production of medical device mold, laboratory consumable molds, nucleic acid extraction tube molds, virus detection card molds, virus sampling tubes, precision medical molds, medical molds, medical equipment molds, centrifuge tube molds, tip molds, PCR molds. The company is located in Huangyan District, Taizhou City, the hometown of Chinese molds, where the transportation is convenient, and it is very close to the railway station and the airport. The company focuses on the research and development of precision molds and product processing for disposable medical consumable plastic products, and can design and manufacture various molds according to customer requirements. The company has a group of mold engineers who have been engaged in mold manufacturing for more than 20 years, as well as experienced product designers. The company has complete production equipment, thoughtful service, punctual delivery, quality assurance and reasonable price. Our company’s business philosophy: win customers by integrity, seek long-term cooperation by quality. Welcome customers and friends to inquire and cooperate.

Disposable Medical mould and Laboratory consumables products mould professional production factory from Huangyan,Taizhou of China.

Disposable medical injection products are more common, including test tubes, petri dishes, measuring cups, centrifuge tubes, etc. WS Mould has 20 years of experience in pharmaceutical laboratory (consumables) mold manufacturing.

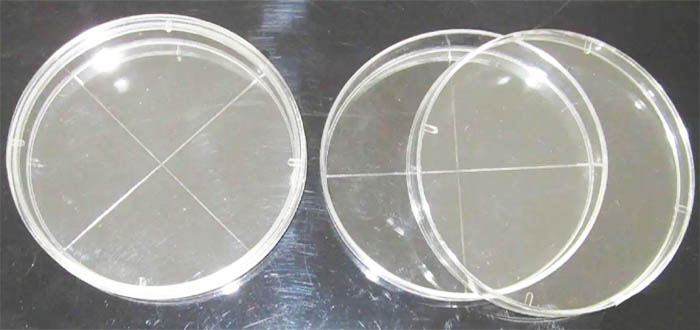

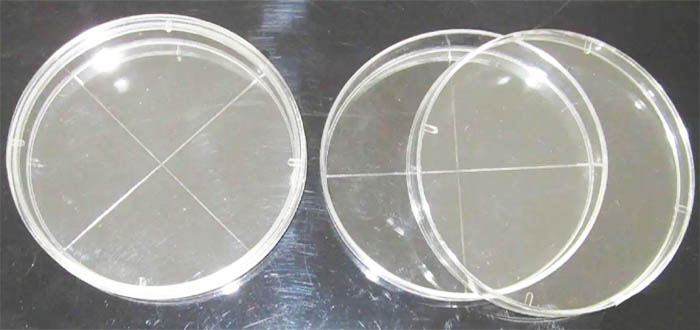

Test tubes, petri dishes and colorimetric cup are mostly made of PS plastics material and those items have a high concentricity requirments. As we know, PS material products can easily get scratches, so it needs supreme grade polishing. WS Mould uses mirror polish and has artificial polishing to ensure high quality polish and reduce the scratches.

For medical consumables molds, the mould dimension must be controlled in precision. We always use high speed milling machine and some other high precision tooling machine to process all kinds of medical divice moulds, the dimension tolerance can be controlled in 0.02mm.

To make a excellent quality disposable medical molds, we will choose the suitable steel material for the medical molds. The common steels we apply into the medical moulds have S136, NAK80, H13 with 45-50HRC. Then the molds can be achieve a long mold life at least 3 million shots and running for 3-5 years continuously.

Urine Sample Cup Moulds Specimen Container Molds

Urine Sample Cup is a container cup for collecting and storing solid or liquid samples.

WS MOULD is a factory specializing in the design, manufacture, plastic molding and processing of precision medical Urine Sample Cup Moulds.

We can produce Specimen Container Molds of various specifications, including 10ml, 20ml, 30ml, 40ml, 60ml, 100ml, 120ml and so on.

The materials of Urine Specimen Cup are usually polypropylene (PP), polystyrene (PS), and technical solutions for stool cup moulds or sputum cup moulds are provided.

Product details of Urine Container Cup Mould by WS MOLD:

★ Produces disposable medical sample collection cup molds of various styles and capacities, which are widely used in the collection and experimentation of sputum, urine, feces, semen and other different specimens.

★ LOGO or other designs can be made according to customer needs.

★ High-quality materials, exquisite molds and craftsmanship, the urine cups produced have good sealing properties, effectively prevent leakage and contamination of specimens, facilitate preservation and transportation, and prevent patients and medical staff from contacting specimens, which is safe and reliable.

★ The high-quality mold steel ensures that the Urine Cup produced has good chemical resistance, ensures the quality control before analysis, and provides a strong guarantee for the standardization of specimen testing.

40ml 60ml 120ml screw mouth Urine Container Moulds stool cup sampling cup measuring cup phlegm cup mold Specimen Container Molds custom production.The design and production of disposable plastic Specimen Container Molds has first-class production equipment, strong mold strength, superb mold technology and mold technology, and can develop new products according to customer requirements.

Medical device moulds manufacturer that supply components molds to the medical device industry,injection molding is a important manufacturing method for plastic medical devices. It has a high degree of design flexibility, injection molding is capable of producing a large quantity of parts per hour.Used properly designed and built tooling molds, the defective rate is very low and little if any post-production work is needed.

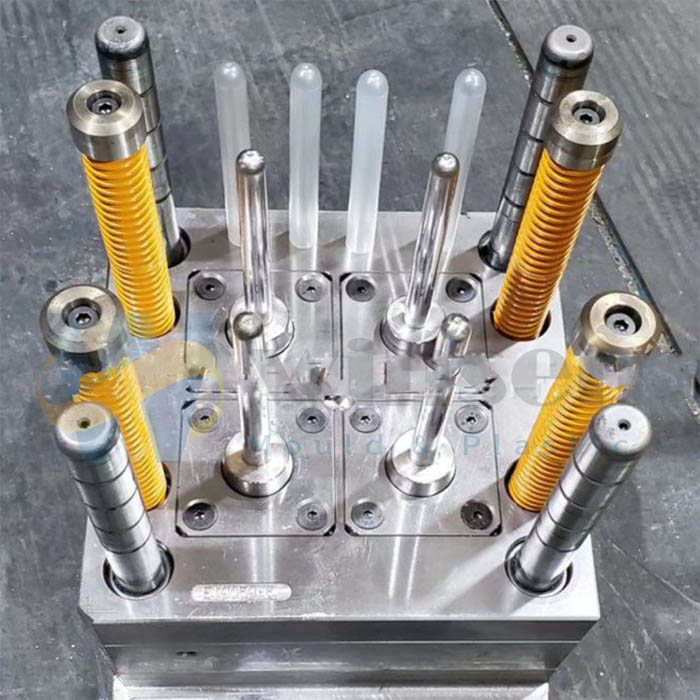

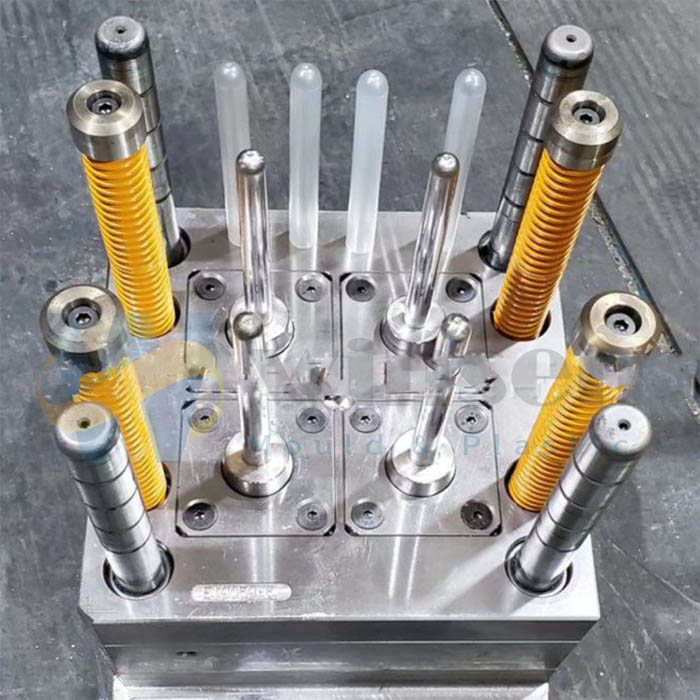

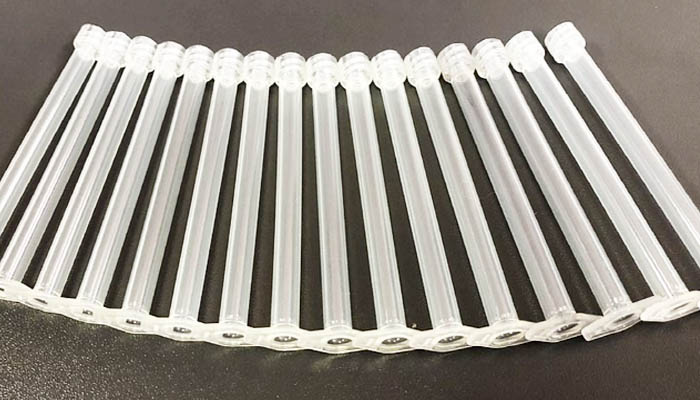

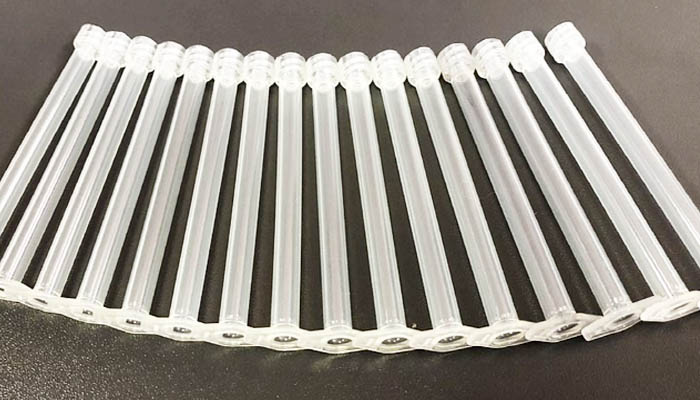

PP and PET test tube moulds

The materials of plastic test tubes are usually PE, PP, PS, PET, etc.The test tube of PET material is a vacuum test tube.

Daily virus sampling tubes are used to collect influenza virus, hand-foot-mouth virus, measles and rubella virus and related samples. It is stored and shipped at 2-8°C for a short period of time and at -80°C in a refrigerator or liquid nitrogen environment for a long time.

2ml 5ml 7ml 10ml 12ml 20ml 30ml multi-cavity plastic injection test tube molds custom production.

As one of the necessary medical consumables, plastic test tubes are used in a large amount. Coupled with the impact of the epidemic, the market demand for test tubes is also increasing day by day, and more and more companies have turned their investment targets to the medical consumables market. We have been committed to the research and development and production of medical disposable test tube molds. due contribution.

We provide solutions for test tube molds, perfect quality control and management of test tube molds, and guarantee to provide customers with high-quality test tube mold services.

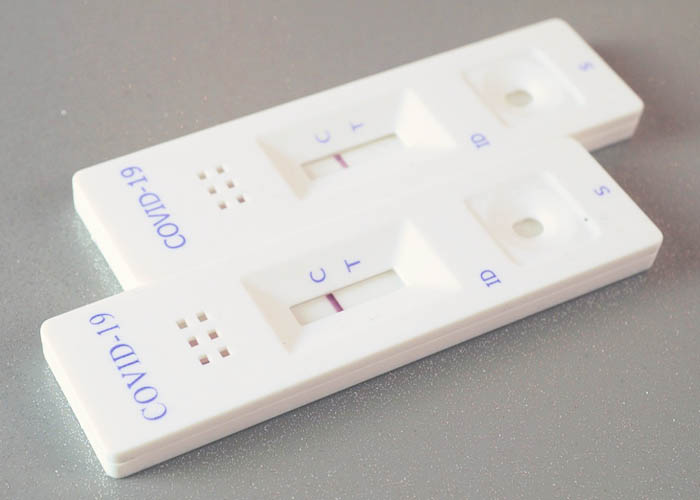

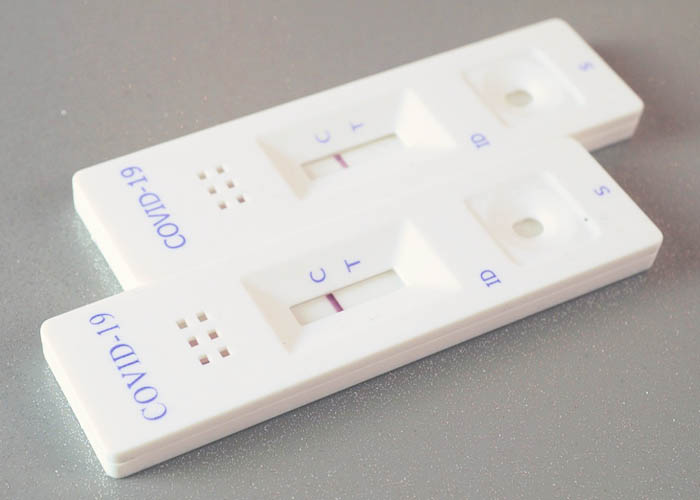

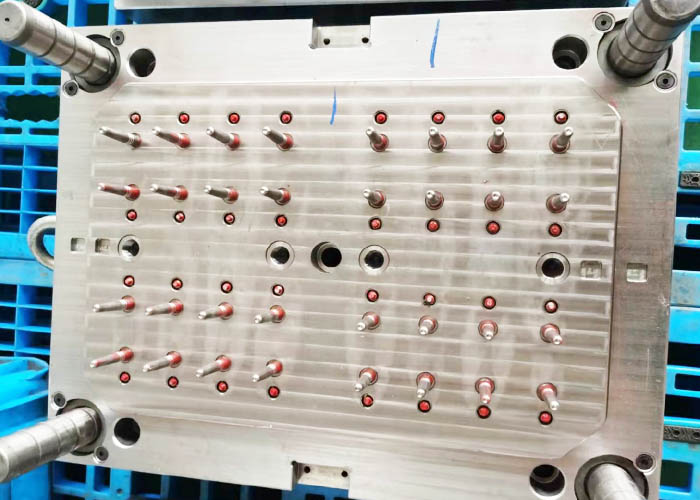

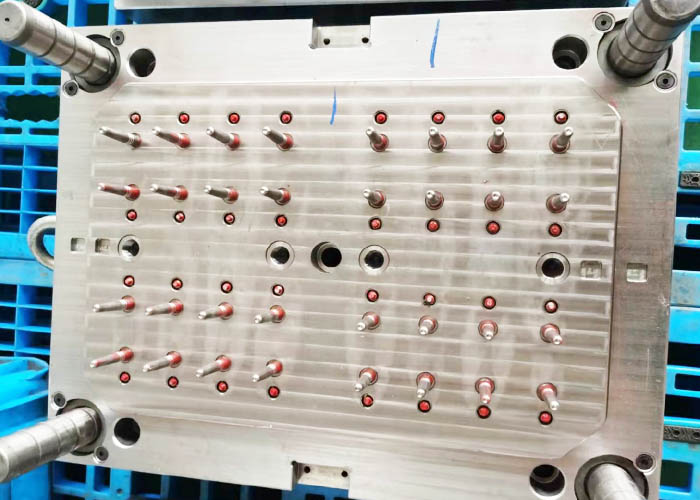

COVID-19 self-test box mold cassettle mould

The nucleic acid detection reagent plastic cassettle for nucleic acid detection, also known as the gold standard cassettle, is generally produced with white PS material and has good performance.The test test box is also widely used in food safety testing such as clenbuterol, melamine, and antibiotics.

Customized production of H13 high-quality New coronavirus detection reagent plastic shell mold. The company has advanced and precise medical mold production equipment. It integrates product and mold design, sales, and research and development, and strives to create high-end medical product mold quality in the industry. With professional production experience, mature technology and advanced management, the medical COVID-19 self-test box mould produced has been well received by customers. With good quality and good service, a stable customer base has been established.

The regular specification of the gold standard plastic card case is 70*20*6mm and 100mm*16mm*4.3mm.

We have been committed to providing customers with economical and reasonable medical cassette mold solutions. Our goal is to be customer-oriented, driven by technological innovation, based on quality assurance system, and use technology and services to help customers stay in the same industry. leading level.

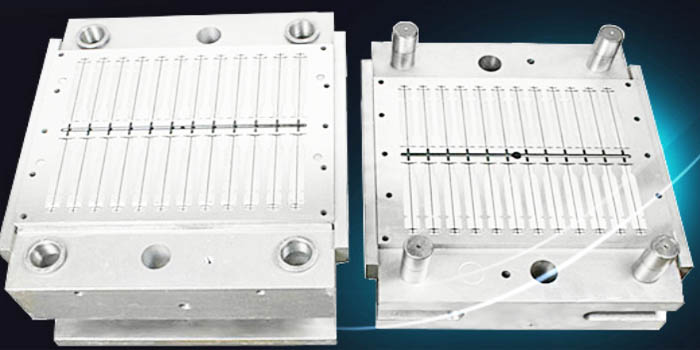

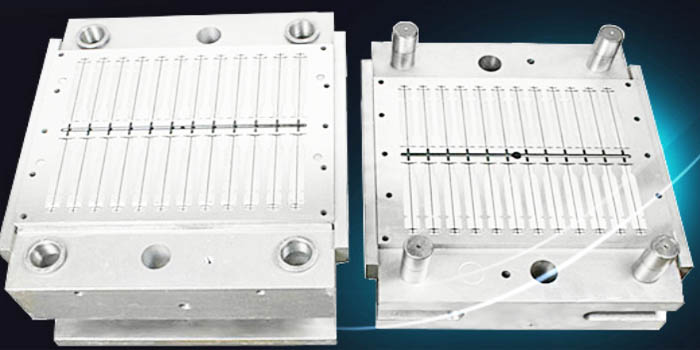

Centrifuge tube injection mold

A centrifuge tube is a tubular sample container used for the separation and preparation of biological samples using centrifugation technology. The centrifugal force provided by the high-speed rotation of the centrifuge causes the tiny particles in the liquid to settle and separate from the solution. The centrifuge tube is made of polypropylene, a transparent polymer material, which is widely used in various experimental operations and meets the requirements of biological analysis.

Centrifuge tube mold customization Sample tube customization and processing flow: 3D design – drawing and confirmation – material preparation – mold base processing – mold core processing – mold parts processing – inspection – assembly – mold trial – customer Feedback Confirmation – Shipment

Processing equipment: CNC milling, engraving, EDM, wire cutting, drilling machine, grinding machine, ordinary milling machine, CNC machining center.

WS Injection Mold Factory adopts computer professional design, CNC precision machining of various specifications of centrifugal tube molds, and can customize injection molding centrifugal tube products according to customer requirements.

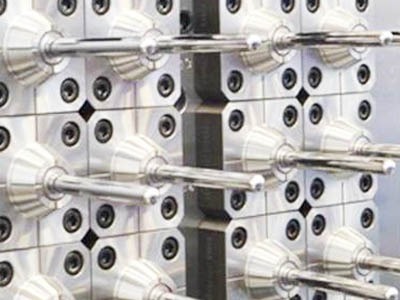

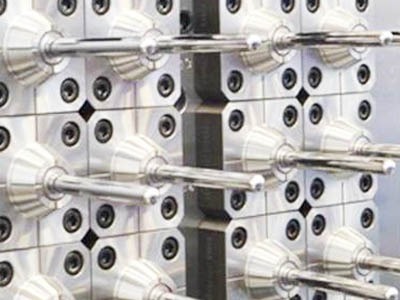

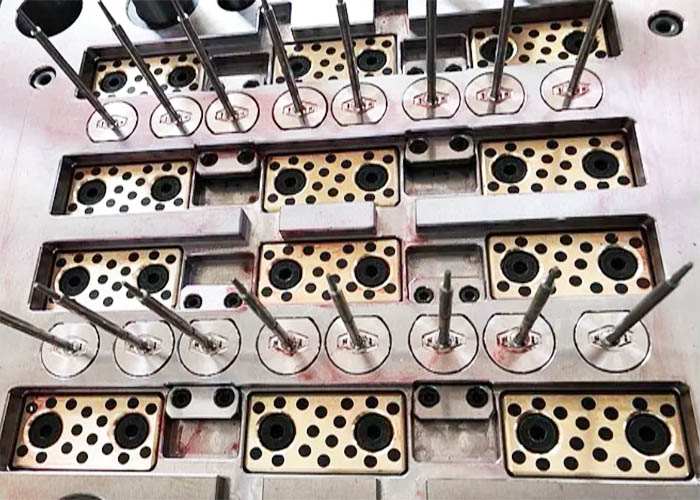

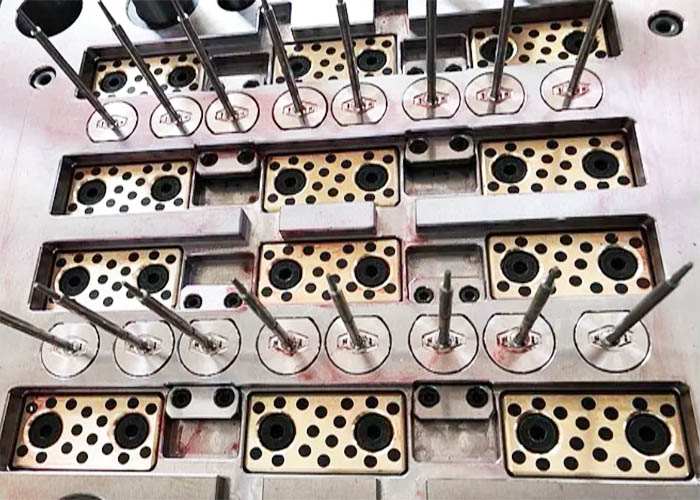

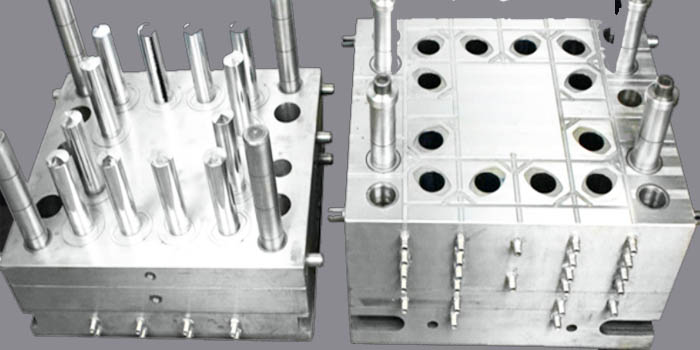

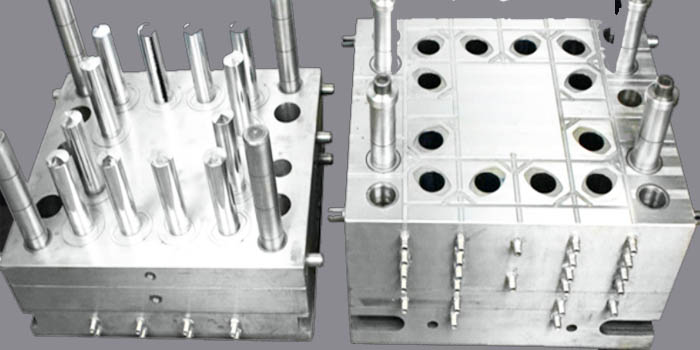

Pipette Tip Mould

The multi-cavity pipette tip mold is customized production, the mold cycle time is 15-18s, the cycle is short and the quality is high. WS Mould focuses on the design, development and manufacture of 12-64 cavity pipette tip moulds. High-precision processing equipment, strict quality inspection standards, the achievement of high-quality molds. The product is not eccentric, the inner surface is smooth, and the quality is reliable!

Pipette Tip Mould Details

Product Name: Pipette Tip Mould

Plastic material PP

Cavity core steel: S136 and 50~52HRC

Steel used for mold base: pre-hardened

Mould accessories: Compatible with DME/HASCO standard

Mold life: 200,0000 or more injections of pre-hardened material under normal use

Runner: hot runner point gate or needle valve hot runner

Delivery time: 50 days after prepayment

Packing: Standard fumigated wooden box

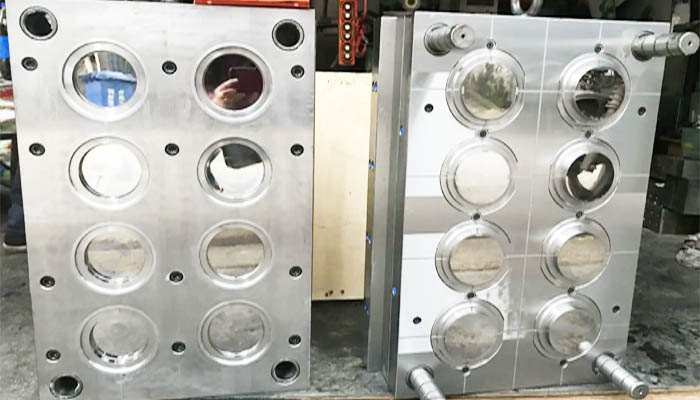

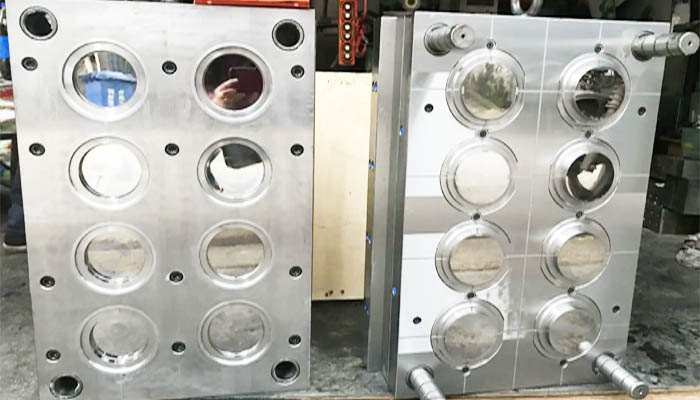

Petri Dish Mould

Microbial petri dish, petri dish for sedimentation bacteria detection, standard 90mm, in line with GMP requirements. Not broken, used many times. Strong like metal, more transparent than glass—commonly known as metallic glass, resistant to high temperature.

Taizhou Huangyan WS Mould Co., Ltd. is a professional manufacturer of precision medical product moulds, and the precision of moulds can meet customer requirements.

Petri dish Mold steel material: H13, S136, 2316, etc. Head, cavity vacuum quenching, mold base P20# heat treatment.

A project is a collision of trust, and a client is a lifelong friend!

We are committed to being your worry-free medical mold partner, happy cooperation and win-win development!

100% commitment to after-sales service: mold warranty for 1 year, free maintenance during the warranty period!

Disposable Syringe Mould

A syringe is a common medical device. As early as the 15th century, the Italian Cartinel proposed the principle of the syringe. The main use of needles to extract or inject gas or liquid.

Syringes can also be used in medical devices, containers, and scientific instruments such as some in chromatography to inject through rubber septa.

1/2/3/5/10/20ml Syringe Mould, Vaccine Syringe Mould, Safety Injection Needle Mould Customized Production.

Information on Medical Syringe Molds

Syringe: PP

Syringe plunger: PP

Syringe stopper: TPE or TPU

Product volume: 1ML, 5ML, 10ML, 20ML, 25ML

Syringe mold cavity number: 12-64 cavity

Syringe push rod mold cavity number: 6-48 cavity

Syringe plug mold cavity number: up to 144 cavities

Cavity core steel: S136

Steel used for mold base: 4CR13 pre-hardened

Pretreatment cavity core steel hardness: HRC 33 ~ 36

Heat Treated Steel: HRC 50 ~ 52

Mold life: Under normal use, the mold life can be as long as five million molds or enjoy a one-year warranty

Hot runner: point gate hot runner

Delivery time 60 days after prepayment

WS has accumulated more than 20 years of medical syringe mold technology in the design and production of medical device molds. It has invented a 72-cavity high-efficiency syringe mold with full hot runner, which is the best choice for high-end syringe manufacturers in the world.

Medical device moulds manufacturer that supply components molds to the medical device industry,injection molding is a important manufacturing method for plastic medical devices. It has a high degree of design flexibility, injection molding is capable of producing a large quantity of parts per hour.Used properly designed and built tooling molds, the defective rate is very low and little if any post-production work is needed.

Medical product mold custom production

1. Mold Steel

We use high-strength mold materials for the production of medical molds, cores, cavities and related inserts for medical molds, we use high-grade plastic mold steels, commonly used mold steels are: 2083, 2344, 2311, 2316, 2738 , S136, etc.; and professional heat treatment companies heat the main part of the medical mold, the hardness of the material is generally more than HRC45, and the mold base is generally P20H or 718H;

2. Design of the mold

We use high-strength mold materials for the production of medical molds, cores, cavities and related inserts for medical molds, we use high-grade plastic mold steels, commonly used mold steels are: 2083, 2344, 2311, 2316, 2738 , S136, etc.; and professional heat treatment companies heat the main part of the medical mold, the hardness of the material is generally more than HRC45, and the mold base is generally P20H or 718H;

3. Mold parts processing

Use high-speed CNC machining center to process medical molds and carry out standardized operations; ensure the accuracy of each medical mold’s parts, and make each part interchangeable;

4. Fast cycle times

The perfect cooling water circuit is designed on the medical mold, combined with the use of fast cooling materials, the cycle time is optimized, the production is more rapid and stable, and the production efficiency is improved;

5. Selection of the number of cavities of the mold

4 cavities; 6 cavities; 8 cavities; 12 cavities; 16 cavities; 24 cavities; 32 cavities; 36 cavities; 48 cavities; 72 cavities;

6. Hot runner system of mold

The high-quality hot runner system developed by ourselves or the hot runner system of well-known brands can produce perfect plastic medical products after optimizing the gate of the mold; all parts of the hot runner of the medical mold are made of high precision, high hardness, ultra-high precision Wear-resistant material

7. Mold delivery time

Fast delivery time, the delivery time of medical molds is generally controlled within 60 working days;

Key points in the design of precision medical device product molds

As a leader in the mold manufacturing supplier of disposable medical device products, WINSEN is committed to the research and development, production, sales and service of disposable medical consumable molds. We can provide customers with and assist in perfecting the complete mold configuration scheme for the production of disposable medical devices. The market prospects of precision medical molds are broad. WINSEN molds tell you the following matters to be considered when designing precision medical equipment molds:

1. The shape and dimensional accuracy of the target molded product, the flow direction of the resin, the transmission of the injection pressure, and the solidification of the filled resin. As a mold designer, it is necessary to know the requirements of the product, which is also the source of precision medical mold design. Therefore, the requirements of the product must be well-informed.

2. The characteristics of the object molded product should have a systematic list of the characteristics of the molded product, mainly in terms of materials, the shape of the molded product, and some details on the mold design below will be based.

3. The structure of the mold. The structure of the precision mold is different from that of the ordinary mold. There may be several possible structural design schemes for ordinary plastic molds, but for precision molds, some structures may have certain influences, so some structural schemes for precision medical molds may be very demanding. It is mainly to consider the influence of the mold action on the product.

4. The rigidity and strength of the mold. Personal experience believes that the rigidity of the mold is very important. I often see that the mold base and inner mold material of some molds are very thin. I can only say that maybe his mold can be produced, but the problem of some products is related to the strength of the mold. There is a very close relationship that is sometimes difficult to spot.

5. The glue inlet and the horizontal glue channel are important factors to control the product. The precision mold has certain requirements for the glue feeding method of the product. Making the glue point beautiful will have an unimaginable effect on the product.

6. Mold temperature control circuit, the mold should be controlled at a uniform temperature. It is necessary to set the temperature difference required in the resin flow direction, and countermeasures are required for the portion where the thickness of the meat changes. When the molded product is released from the mold, the mold surface temperature of the product part should be uniform. This requires the mold cooling system to be reasonable.

7. The precision of the precision mold is very high, and the processing method used to process the mold is very important. Dividing the mold cavity of the product according to the shape of the molded product is very common. Therefore, the processing method should be considered when designing.

8. The mold structure should be reasonable to facilitate the addition of other programs. For example, a position may be unsatisfactory. If it is really unsatisfactory after the mold trial, a post-fill plan should be adopted.

Buyers who need to buy medical device molds can call for specific matters, hotline: +86 13456489912

Influence of temperature on mold quality of medical device products

Today, I will tell you the influence of temperature on the quality of medical device molds:

1. Deformation

The stable temperature of the medical device mold and the balanced cooling rate can reduce the deformation of the product. For products with inconsistent wall thickness and complex shapes, deformation due to uneven shrinkage often occurs. Therefore, a suitable cooling system must be used to keep the temperature of each part of the mold and the core basically uniform, so that the mold cavity The plastic melt can solidify at the same time.

2. Dimensional accuracy

Using the temperature adjustment system to keep the temperature of the medical consumable mold constant can reduce the fluctuation of the molding shrinkage rate of the product and improve the stability of the dimensional accuracy of the product. Using a lower mold temperature for disposable medical devices where possible can help reduce the molding shrinkage of the product. For example, for crystalline plastics, because the mold temperature is lower, the crystallinity of the product is low, and the lower crystallinity can reduce the shrinkage. However, low crystallization is not conducive to the dimensional stability of the product. From the perspective of dimensional stability, it is necessary to appropriately increase the mold temperature to make the product crystallize uniformly.

3. Mechanical properties

For crystalline plastics, the higher the degree of crystallinity, the greater the chance of stress cracking of the product, so it is beneficial to reduce the control temperature from the point of view of reducing the stress cracking angle.

4. Surface quality

Increasing the temperature of the medical mold can improve the surface quality of the product, but too low mold temperature will make the contour of the product unclear and produce obvious fusion lines, resulting in an increase in the surface roughness of the product.

Medical Mould Solutions - Pursuit of Perfection

We will create the best medical product mold solutions according to the needs of different customers: from the material PET/PS/PP required by the customer, the size (-0.5 to 50ml), the shape (cylindrical/conical/flat bottom shape), the product Thickness, production capacity, capital budget and other aspects are comprehensively considered, so that efficient plastic medical mold solutions can be tailored for customers.

WS MOLD Sales Engineer – Confirm customers’ specific needs for medical products through communication, strive to maximize customer satisfaction and exceed customer expectations.

WS MOLD medical product designers will design and optimize the best medical product designs.

WS MOLD mold designer will provide the best medical mold design.

WS MOLD mold quotation department will provide customers with the most affordable medical mold quotation.

China Professional Plastic Injection Commodity Mould Manufacturer

OEM & ODM

Our professional designers can meet any of your special requirements.

Quality Control

We will provide the best price and best quality delivery with you.

Customized service

We can customize various molds according to your requirements.

CUSTOMIZATION/Customized service

Custom Plastic Injection Moulds

Our mold steels all have certificates, and the mold life is long; the molds produced by advanced equipment have a tolerance of +-0.01mm; the molded products have a good appearance without any flash.

Custom Plastic Injection Parts

The company has several precision injection molding machines (specs ranging from 100 grams to 20,000 grams), and can process general plastics, engineering plastics and general materials according to customer needs.