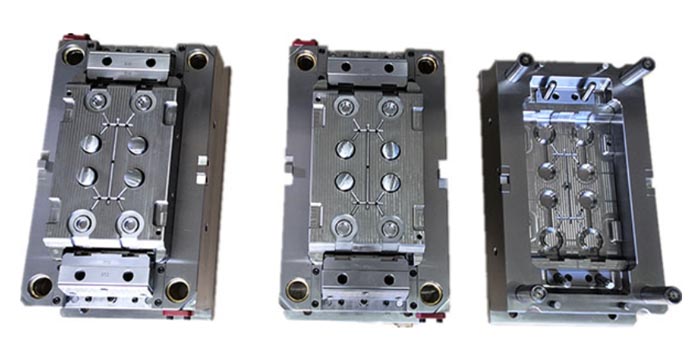

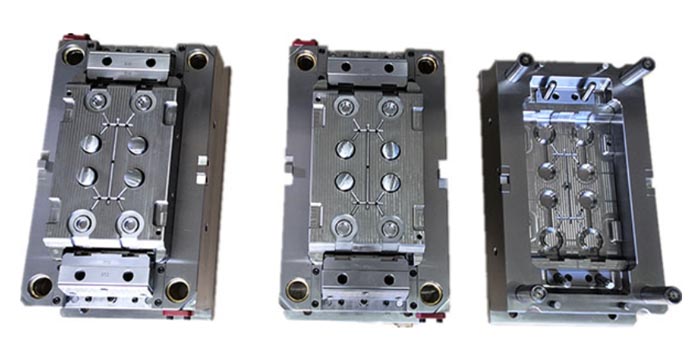

Overmolding Molds & Part

Saves cost and time

No need extra adhesive

Different effect and design

What is overmolding ?

Overmolding is the process of plastic injection molding to add additional layers on the current part.Simply say, overmolding can be plastic wrapping plastic, soft rubber wrapping plastic, or soft rubber wrapping soft rubber.

The methods of realizing overmolding (including coating rubber) can include physical snapping methods and chemical methods. For example, the former relies on snap design, surface tapping, and then covering with a second material to achieve overmolding. The physical connection site has strong adhesion, while the parts outside the physical connection site have little adhesion.

The chemical method relies on the molecular affinity between the two materials and the bonding force of the chemical bond to bond the two materials together to form a single component, two or more.Usually, it begins with injection molding a hard plastic resin,then once that part is cooled, another plastic resin part is injection molded over the first part,the purpose is to create a grip on the original part.

What are the benefits of overmolding?

1. Saves cost and time,this is one of the biggest benefits of overmolding ,due to it can be completed with two runs through our in-house injection molding process at wsmcmold, no need to outsource overmolding to another partner for overmolding,that means there has money and time savings.

2.No need extra adhesive,this also can be save a lot of money. The two pieces are bonded together without adhesive by overmolding. Otherwise, you must be setup an additional manufacturing run to attach the two pieces together with adhesive. You have to make sure the adhesive is compatible with the two materials, or else the parts will degrade and fall apart.

3. Different effect and design, you can combine two different types of plastic resins parts onto one part by overmolding. So you can get a rigid plastic product and then overmold soft rubber onto areas that an end user would grab, for example the handle of a tool. You also can overmold different plastic resins to have two different effect and aesthetic design.

Overmolding Precautions

Overmolding have to considerate that two different materials compatible,chemically and thermally. Because the first part need to put into a plastic injection mold,so it must be that the first part can withstand the temperature needed to melt the second material.Meanwhile,it needs to make sure the two materials don’t react to each other.

In the last, Overmolding is not a simple injection molding process as it is produced from a single material part. Overmolding production requires very rich experience and technology,we are good at do this molding with more than 20 years of experience in plastic injection molding, we’ve successfully completed many overmolding projects for our clients.

Overmolding applications

1. Overmolding Plastic,It is to overmold plastic onto plastic. First, one of plastic component is molded and then the more durable plastic is molded over the first plastic part.

2. Overmolding Metal, Over plastic onto metal is often used for plastic handles on metal tools and components. It’s a process in which plastic is molded over the metal part.

What is the difference between insert molding and overmolding?

Overmolding is an injection molding process that can make parts from two or more materials. Sometimes referred to as “in-mold injection”. Overmolding can be broadly divided into two distinct processes, insert molding and multi-molding. Insert molding is often used to add metal features to plastic parts. Multi-molding is used to make plastic parts from multiple materials in a single molding process to improve external properties such as impact resistance and feel.

Insert Molding is commonly used to add metal parts to injection molded parts during the molding process rather than after curing, thereby reducing post-molding manufacturing/assembly operations. Insert molding is a one-shot molding process.

How long does insert molding mould last?

In general,our injection molds will last well over 100,000 shots. Moreover, wsmcmold offers a lifetime warranty for any injection molds which you purechased from us.

How to work with us for insert molding?

1. Send your drawings to get your mold and part quote.

2. List your requirements for inserts molding, and our project manager will contact you.

3. After order confirmation, wsmcmold starts the mold and part order process.

4. Tooling design review by wsmcmold engineers.

5. when you approval the design, wsmcmold begins building your injection mold.

6. Client comfirm samples for approval,then part production begins.