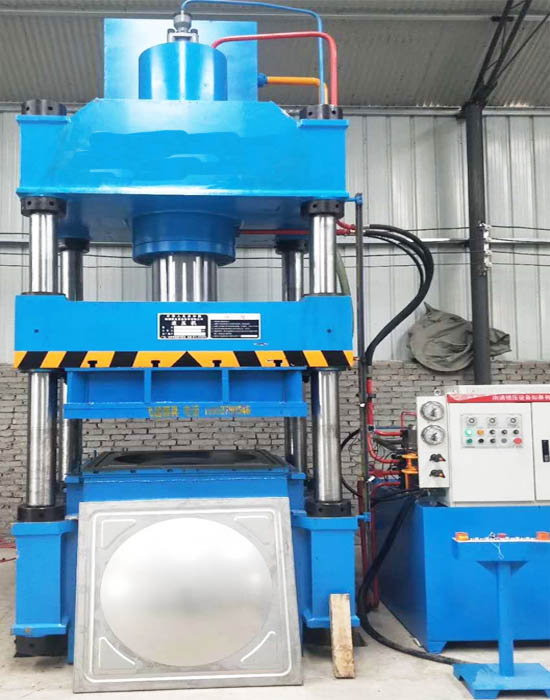

Four Column Compression Molding Hydraulic Press Machine

315 tons, 500 tons, 630 tons, 1,000 tons, 1,500 tons, and 2,000 tons four-column hydraulic press

Four-Column Compression Molding Hydraulic Press Machine Supplier

Tailor-made for users: energy-saving, exquisite and durable hydraulic equipment (hydraulic presses, servo hydraulic presses, four-column hydraulic presses) can provide solutions according to user requirements.

A hydraulic press is a machine that uses liquid as a working medium and is made according to Pascal’s principle to transfer energy to realize various processes. A hydraulic press generally consists of three parts: the machine (main machine), the power system and the hydraulic control system. Hydraulic presses are classified into valve hydraulic presses, liquid hydraulic presses, and engineering hydraulic presses.

A hydraulic press is a mechanical device that uses the static pressure of hydraulic oil delivered by an oil pump to process metal, plastic, rubber, wood, powder and other products with compression molding.

Provide a full range of hydraulic customization services for your compression molding product’s production.

315T Hydraulic Press Machine

The 315 tons four-column hydraulic press adopts an open structure with four columns and three plates. The design of the hydraulic circuit is simple, and the mold is easy to install and disassemble and easy to maintain.

500T Hydraulic Press Machine

The four-column 500T hydraulic press is mainly used for a series of forming products such as metal material blanking, stretching, auto parts, powder product forming, and glass fiber reinforced plastic product forming

630T Hydraulic Press Machine

The four-column hydraulic press, also known as the hydraulic press, is a machine made of Pascal’s law that uses liquid pressure transmission. The 630-ton hydraulic press has a wide range of applications, and has a single-cylinder, double-cylinder or multi-cylinder structure according to different products

1000T Hydraulic Press Machine

The technological action of the 1000T press is fast down of the slider,slow down for pressurization,pressure holding delay,pressure unloading delay,return, and various processes can be customized according to customer requirements

1500T Hydraulic Press Machine

Large-scale 1500T hydraulic press, the hydraulic press has compact structure, high precision, convenient operation, stable work, safety and reliability, wide range of products, and the size of the working surface can be customized. Welcome to consult

2000T Hydraulic Press Machine

Water Cooled Industrial Chiller is Efficient Industrial Cooling,application industry: Water-cooled chillers are mainly used in injection molding,compression molding,chemical industry, mechanical equipment cooling, etc.

4 Column Hydraulic Press Machine servo Metal Hot Press for compression mold

Hydraulic press is also known as oil hydraulic press, it is a machine that uses hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products. It is often used in pressing process and pressing forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet drawing, powder metallurgy, pressing and so on.

Hydraulic Press Machine Features

The control system of the four-column hydraulic press has two working modes: manual and semi-automatic.

The hydraulic system adopts two-way cartridge valve integrated system, and the electrical system adopts integrated circuit control (PLC programmable controller can also be selected). The power system of the four-column hydraulic press is installed on the ground for easy maintenance and repair.

The four-column hydraulic press is equipped with an independent movable control cabinet for easy operation.

The four-column hydraulic press can limit pressure, limit range, position, and process actions.

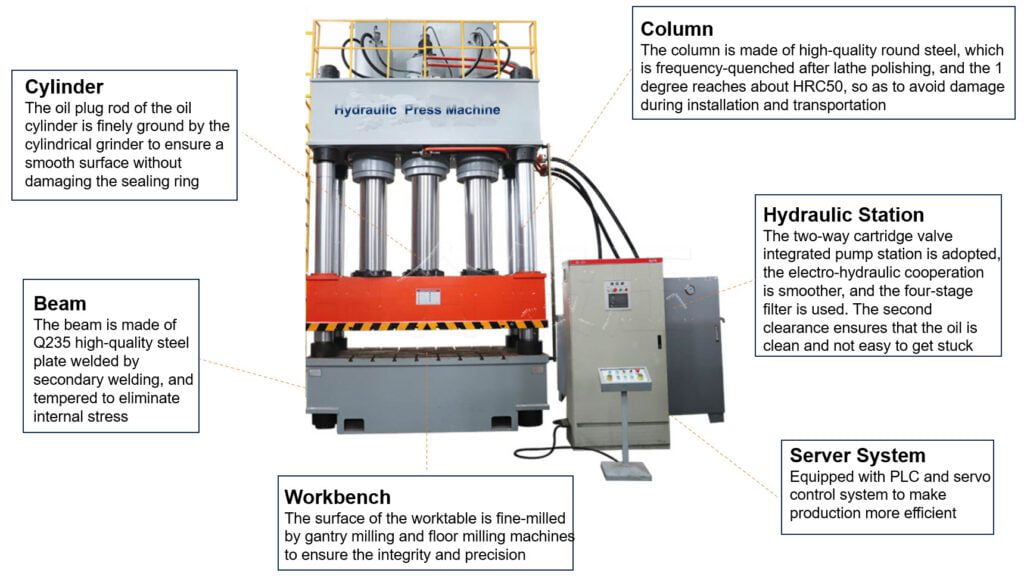

Overview of hydraulic machine structure

The press machine is composed of main body machine, hydraulic system and electric control system.

1.Press Main Body(including the fuselage and oil cylinder)

(1).Fuselage

The fuselage is composed of upper beam, lower beam, slider, column and nut. The upper and lower beams are tightly connected together with four columns and nuts to form a rigid frame. The slider is guided by the column and slides up and down along the column. The upper and lower guide sleeves of the slider are equipped with dust-proof rings to prevent dirt from scratching the cylindrical surface. On the sliding beam and the chess beam, there is a T-shaped groove (the specific size is proposed by the buyer), and the column nut can adjust the unbalance of the working surface and the non-perpendicularity between the workbench and the piston. Large pieces are precision-machined by large-scale CNC floor milling machines and high-precision CNC planer milling machines. The three-beam and four-column structure is optimized by computer and finite element analysis is performed. The equipment has high strength and beautiful appearance.

(2).Oil Cylinder

The master cylinder adopts the piston cylinder structure and is fixed in the center hole of the upper beam with bolts. The cylinder body is rolled, the piston rod is quenched and tempered, and the surface is polished by hard chrome plating, which is wear-resistant, beautiful and corrosion-resistant.

2.Hydraulic control system

(1).Hydraulic device

①.Installation form of hydraulic power station: installed on the ground on the right side of the main engine to minimize noise.

②.The hydraulic power station is equipped with an oil filtering device. The separator separates the oil suction area from the oil return area, and there is a filter at the oil filling port to ensure the cleanliness of the hydraulic oil.

③.The liquid level of the fuel tank is displayed by the liquid level gauge.

④.Cylinder liquid filling system: The liquid filling valve is installed at the bottom of the oil cylinder. The structure is a normally closed self-priming type. When the slider moves down quickly, the filling valve is sucked open by its own weight and sucks oil from the liquid filling tank. ⑤ High-pressure resistant seamless steel pipes are selected for pipelines, and high-pressure oil pipes are used for connection at the pipe heads.

(2).Hydraulic control system

①.The working pressure of the hydraulic system is 25MPa, and the rated pressure of the components is 31.5MPa, which is beneficial to improve the life of the components of the hydraulic system.

②.The high-pressure main oil pump is made of domestically produced high-quality axial piston pump, which is driven by a motor. Usually the main oil pump motor unit is installed horizontally.

③.The hydraulic control system adopts a two-way cartridge valve integrated system. It has the advantages of small oil resistance, large flow rate, anti-pollution, fast response, high safety and reliability, flexible control mode and convenient maintenance.

④.Two-way cartridge valve integrated design, reasonable layout, easy to manufacture, very convenient to debug and maintain.

⑤.The hydraulic control system realizes the following main functions respectively:

a) Pump head control circuit—consists of check valve and relief valve to realize system pressure building and control main pump overload and unloading.

b) The pressurization circuit of the main cylinder – controlled by the two-way cartridge valve and its pilot solenoid, to realize the stepless adjustment of the loading force of the press.

c) Pressure setting circuit – adjusted by the pressure valve of the main system to realize the action of ejecting the cylinder.

3.Electrical control system

The main control system of this machine adopts an integrated circuit controller, and various buttons are installed on the operation cabinet. The operation cabinet is placed on the workshop floor next to the hydraulic press, which is convenient for operation and observation.

①.The main control of the electrical system can realize various process action cycles of the hydraulic press; this machine has two working modes, manual and semi-automatic, which are converted by a switch.

②.Power part: control the main power supply and the start-stop and protection switches of each motor.

③.Control part: It can complete the control operation of all the actions of the machine. The operation panel is also equipped with operation buttons and function switching switches for each part of the main engine, and start and stop buttons for each motor.

Contact Us Now For Your A Complete Set Of Solutions For The Hydraulic Industry

If you are interested in hydraulic press machines, you are welcome to contact us. We will wholeheartedly provide you with technical solutions related to hydraulic machines, and tailor high-quality hydraulic equipment for you to meet your production process needs.

Hydraulic press machines are mainly used in composite materials production process of compression molding and thermoforming

Hydraulic press machine for ballistic helmet mold

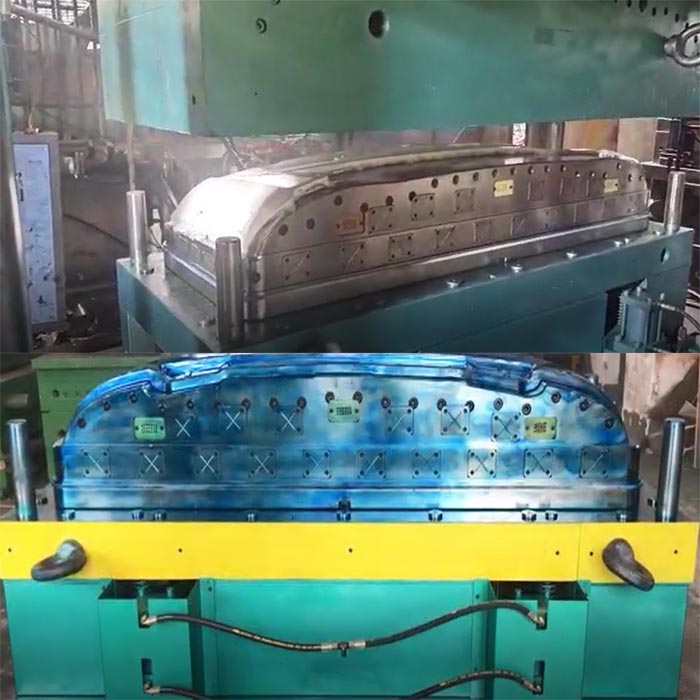

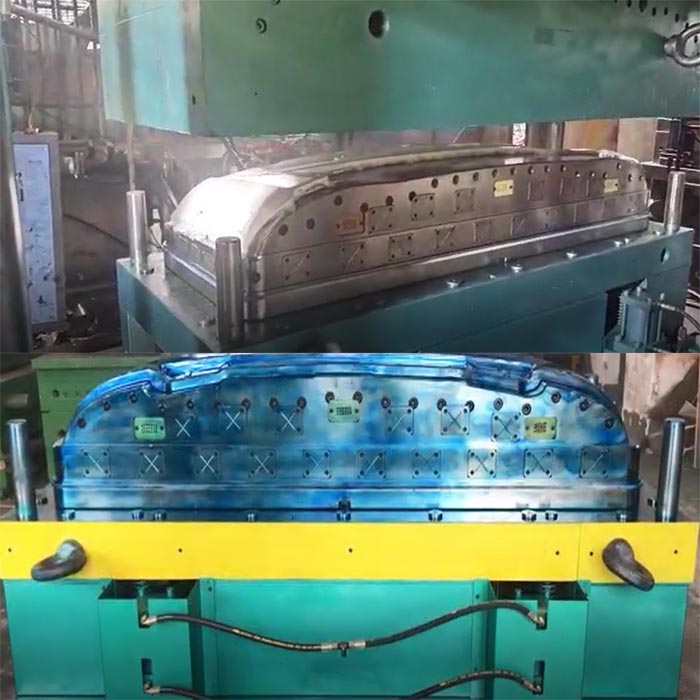

Special hydraulic press for fiberglass auto bumper mold

Hydraulic press machine for SMC BMC meter box mold

The hydraulic press can be customized according to the required process. According to the structural form, it is mainly divided into: four-column type, single-column type (C type), horizontal type, vertical frame, four-column hydraulic press, etc. Among them, the four-column hydraulic press can be divided into four-column two-beam hydraulic press, four-column three-beam hydraulic press, four-column four-beam hydraulic press and so on.

Customized production of a series of large-scale hydraulic equipment such as forging hydraulic presses of various specifications, providing a full range of services for industrial production, auto parts, plastic products, and powder pressing.