Capabilities

We are a reliable manufacturer in Taizhou,China for custom compression molding and plastic injection moulding, CNC machining and your rapid prototyping manufacturing source. We will follow up your 2D and 3D models drawing or samples to make your compression and plastic parts to your specifications. We have many different composites and plastic materials available, and many steels of molds and surface finishes to run. There are also secondary processes to help you do one-station service, such as mass production of final shaped products, printing and chrome plating.

When you’re going to work your custom composites compression and plastic injection molding or CNC machining project with us, it’s fast to get started. Just submit your drawings or samples, specify your requirements like quantity, material and ect.You will see your molds cost and piece unit price within 2-4 hours.

We will work together with you from the initial quotation to through the delivery of your parts to gurantee that you’re happy with our service. Click on the links as follows to learn more about the services we provided.

Molds Moulding

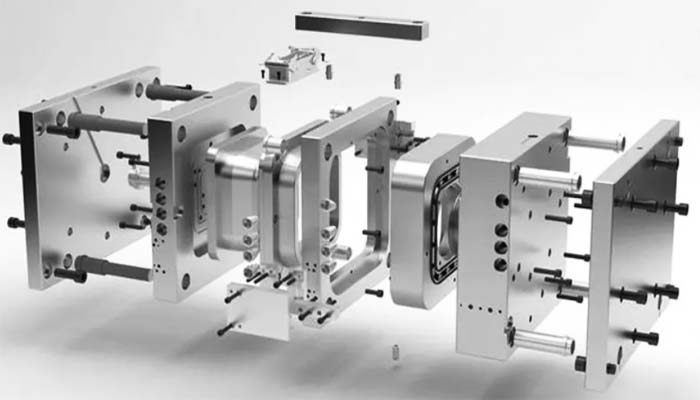

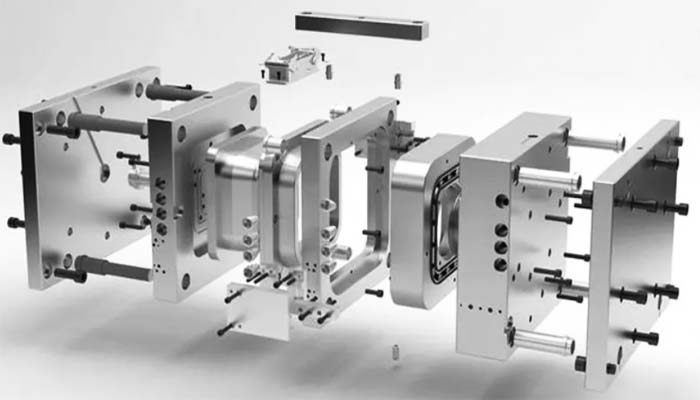

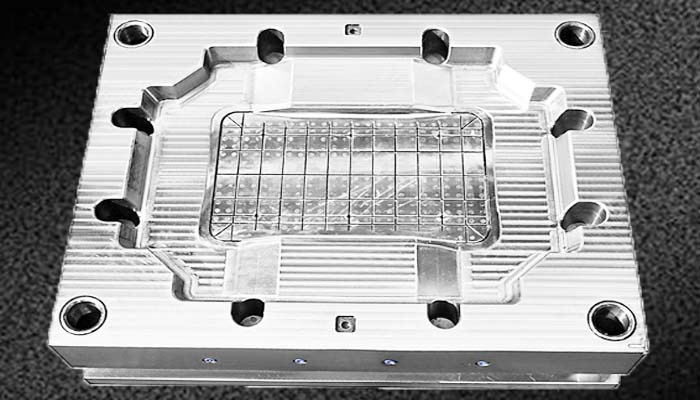

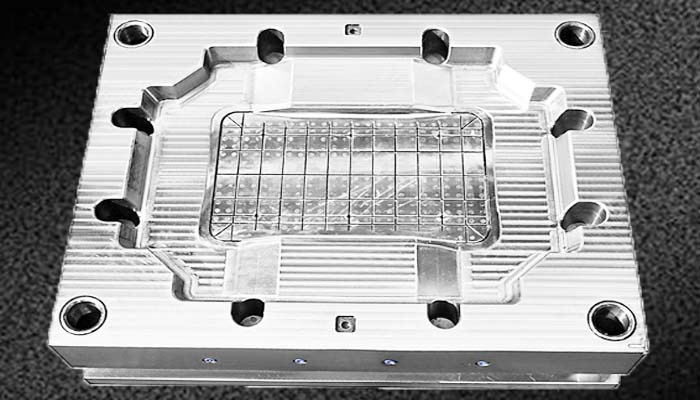

Injection Molds

Compression Molds

Molds Making

Molding Options

Family Molds

Insert Molding

Overmolding

CNC Machining

CNC Milling

CNC Turning

CNC Drilling

CNC machining Plastics

CNC machining Metals

Urethane Casting

Process Overview

Applications

Materials

Finishes

Advantages

Comparison to Plastic Injection Molding

Additive Manufacturing with wsmcmold.com

3D Printing Services

Additive Manufacturing Quotes

3D Printing Prototypes

Wsmcmold is a Leader in Composites Compression Molding and Plastic Injection Moulding for China Companies

Mold and Part Molding Services

One-stop machining of CNC molds and parts - quick proofing

We Offer Solutions for Compression Molding and Injection Moulding

Our products are aimed at precision parts manufacturing in all walks of life, military industry, aerospace and defense, automobiles, daily necessities, new energy, industrial products, medical equipment, etc., providing strong support for your custom mold and component production.