Products

Plastic Injection Products

Hundreds of specifications, must belong to

Customized design and processing of various plastic products, our top hot selling lithium battery case car auto battery box, motorcycle battery sheel,PET preforms with various sizes and weights,in molding label(IML) injection molding paint bucket from 1L to 20L with designed labels according to your requirements.

With advancements in technology and manufacturing processes, custom plastic product design and processing have become more accessible and cost-effective. It has opened up new possibilities for various industries to create unique and innovative products that were previously not possible.

Lithium Battery Case Auto battery Box Motorcycle Battery Shell

Personalized custom battery box new energy car battery case,print LOGO, text and custom colors according to customer requirements

Plastic Injection PET Preform

The PET preforms produced have complete specifications, and are widely used in blowing various specifications of food packaging cans, medical chemicals, mineral water, beverages, fruit juices, oil products, daily chemical washing and other beverages and foods, etc. PET packaging bottle.

IML Paint Bucket Plastic Barrel

Produce customized in mold labeling (IML) Paint Bucket according to customer requirements, can customize label design and color of plastic paint barrel pail

Composites Compression Products

Customized mold opening and processing according to your products and requirements

Compression molding is a versatile manufacturing process used to produce a wide variety of parts and products made from materials such as composites and thermoplastics. The process involves placing raw material in a heated mold and compressing it under high pressure until the material takes on the shape of the mold. With its ability to produce complex parts with tight tolerances and consistent quality, compression molding is an ideal solution for a wide range of industries including aerospace, automotive, medical and consumer goods. In our company, we specialize in the custom design and production of compression molded parts and products to meet the unique needs of our customers. Our experienced team of engineers and technicians work closely with customers to develop solutions that are cost-effective, performant and delivered on time. Whether you need a small number of custom parts or a high volume of a specific product, our compression molding services provide a reliable and efficient manufacturing solution.

Fiberglass(FRP) compression auto parts

Can undertake a large number of order, support custom design and production for fiber glass compression automobile parts

SMC BMC FRP compression cable support holder bracket

Compression composites cable support Corrosion resistance, strong shock resistance, high pressure resistance, and various holder bracket connection methods

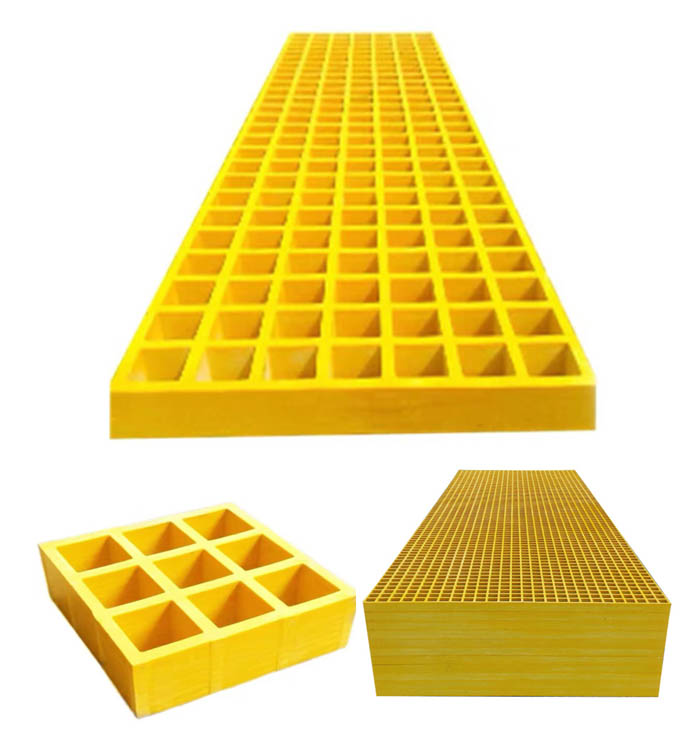

Fiberglass grille cover plate SMC BMC FRP compression sewage drain grille

The thickened and upgraded material for fiberglass grille cover plate,it is more firm and durable, and has good aging resistance. It is a product made of glass fiber reinforced material and unsaturated polyester resin based on special processing and compounding

One-stop Caring Service

Scheduling An Appointment

Integrated solutions, based on the industry for more than 20 years "Strict quality control ,your satisfaction is our direction" make every product with heart !