Static Charging Generator for IML(In Mold Labeling) injection molding

Help you reduce product defect rate and improve production efficiency

Make IML product more stable and comfortable,100% injection success rate!

In mold labeling IML film lable static charger generator Plastic injection Electrostatic charging generator manufacturer

The Static Charging Generator mainly generates static electricity. The output is usually a single polarity, such as positive or negative, and the output voltage can be adjusted. Electrostatic generator has a wide range of uses, involving packaging, printing, plastics, textiles, painting, woodworking, papermaking, metallurgy, Agricultural production, aviation and many other fields,especially provides a robust solution for IML(In Mold Labeling) injection molding production processes,maximizing the efficiency of the application.

Static charger generator can meet the needs of customers in plastic injection industries for electrostatic equipment, and will provide customers with the most reasonable solutions with the most professional skills.We offer electrostatic charging generator solutions for various manufacturing processes and aimed at increasing productivity and quality.

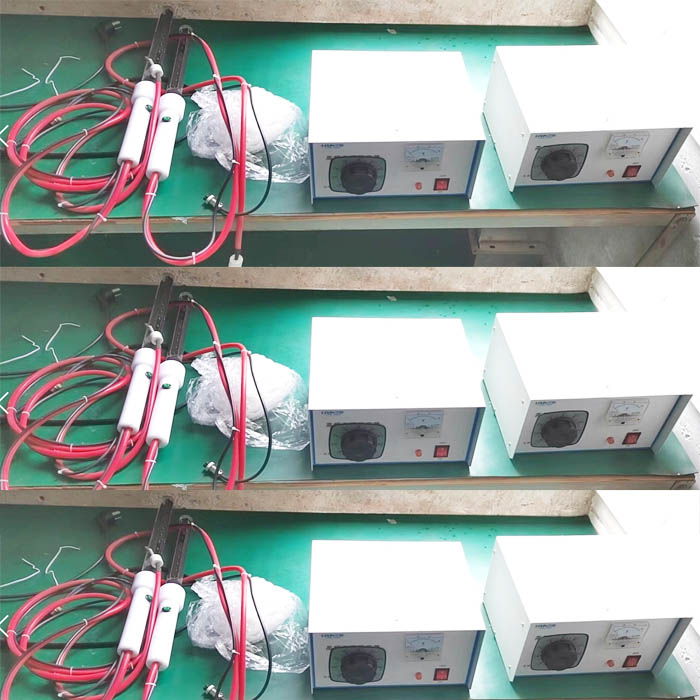

In Mold Labeling IML Static Generator Device

Static Generator Device used for in mold labeling( IML) plastic injection production,after adding static electricity to the label, it can be better pasted on the mold and reduce the defective rate of injection molding

In Mold Foil IML Static Generator Equipment

Static Generator Equipment for In Mold Foil IML,plastic films and labels,which is special customized production for in mold label,static generator is directly installed on the manipulator

IML Label Film Static Charging Generator Machine

IML Label Film Static Charging Generator Machine has been verified by many enterprises and manufacturers, and has excellent performance and long service life. It is widely used in every industry

IML 20KV Electrostatic Charge Generator Machine

Electrostatic Charge Generator Machine (electrostatic machine) is an electromechanical generator that generates static electricity in, or electricity of, high voltage and low current continuously,When the robot places the label on the mold, the electrostatic generator is controlled by PLC to power on the label, and the label will be adsorbed on the mold

Plastic Injection Industrial Static Generator

Plastic Injection Industrial Static Generator utilizes the electrostatic electrostatic field under the action of the electrostatic field.The characteristics of the temporary adsorption material, to achieve plastic labels sticks well on mold for better injection molding,helping to maintain product quality and productivity for injection moulding

In Mold Labeling IML Static Generation Charging Equipment

In Mold Labeling IML Static Generation Charging Equipment uses the high voltage generated by the electrostatic generator. The electric charge moves to the surface of the product under the action of the electric field.The robot picks up the label, electrifies the label through an electrostatic generator, and finally puts it into the mold

Battery Box Mold making Plastic Battery Box for Lithium Battery

Car Battery Storage Box Mold producing Lithium Ion Battery Box Enclosure

Contact Us Now For Your Static Generator In Plastic Injection Field Solution

Static chargers that can be used to stick PP, BOPP, polystyrene foil material to the inner mold surface during injection molding. This makes the foil constant in a position in the mold due to charging. These static chargers are manufactured in compliance with international quality & safety standards. Decorate your injection moulded product to look more charming

Because an in-mold label or decoration is embedded in the wall of the product through plastic molding injection, it is very durable and nearly impossible to remove from the object. For injection molded tubs, all four sides and the bottom can be decorated with a single label during the molding process, something that pressure-sensitive labels cannot do.

We provides a robust solution for a wide range of production processes maximizing the efficiency of the application.

Contact me for detailed and quotation !

More Electrostatic Generator Models

Electrostatic charge generator Industrial Static Control

Static Generation Equipment Static Charging Generator

IML in mold labeling static charging equipment 20KV 30KV 80KV high voltage generator static with charging bar

Application range of electrostatic generator

1. Textile mills, non-woven industry

2. Printing industry

3. Painting and film industry

4. Bioengineering, other industries that need to add static electricity

An electrostatic generator is – a kind of electrostatic application equipment. The electrostatic generator is composed of electrostatic emitter (rod) and DC high voltage power supply. The DC high voltage power supply provides the ion emitter (rod) with negative (or positive) high voltage, so that the ion emitter (rod) emits negative ions (or positive ions) and then charges the object (workpiece) (artificially charged). The higher the voltage, the larger the effective range.

In-mould decorating is a process for labeling or decorating a plastic object during the plastic injection molding process. In the in-mold labeling process, a label or appliqué is placed in the open mold and held in the desired position by vacuum ports,electrostatic attraction or other appropriate means. The mold closes and molten plastic resin is extruded or injected into the mold where it conforms to the shape of the object.

Static charges can be used to pin a decorative label tight against the inner mould surface during injection moulding without the use of vacuum. This procedure greatly improves finished product quality. Outside the mould a robot presents the label to a charging bar which applies an electrostatic charge to the label. The label is then placed into the mould cavity, where it sticks due to the electrostatic bond between the label and the metal mould wall. The label will not slip or change position in the mould.

Electrostatic generators are effectively used in the injection molding process of plastic products with in mold labeling IMl film.When the electrostatic generator is used, the level of the output of the electrostatic generator can be adjusted according to the site conditions to adjust the size of the adsorption force.

Electrostatic generators are widely used in packaging, printing, plastics, textiles, painting, woodworking, papermaking, metallurgy, agricultural production, aviation and many other fields. And there are a wide variety of products. The successful IML in-mold labeling solution can meet the needs of customers in various industries for electrostatic equipment and will provide customers with the most reasonable solutions with the most professional skills.