High-end plastic food container injection mold secrets

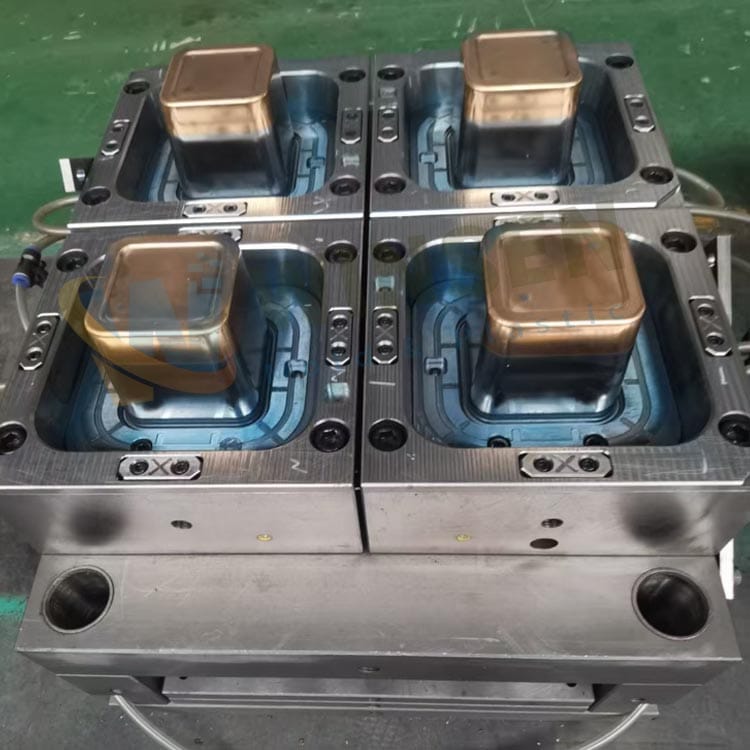

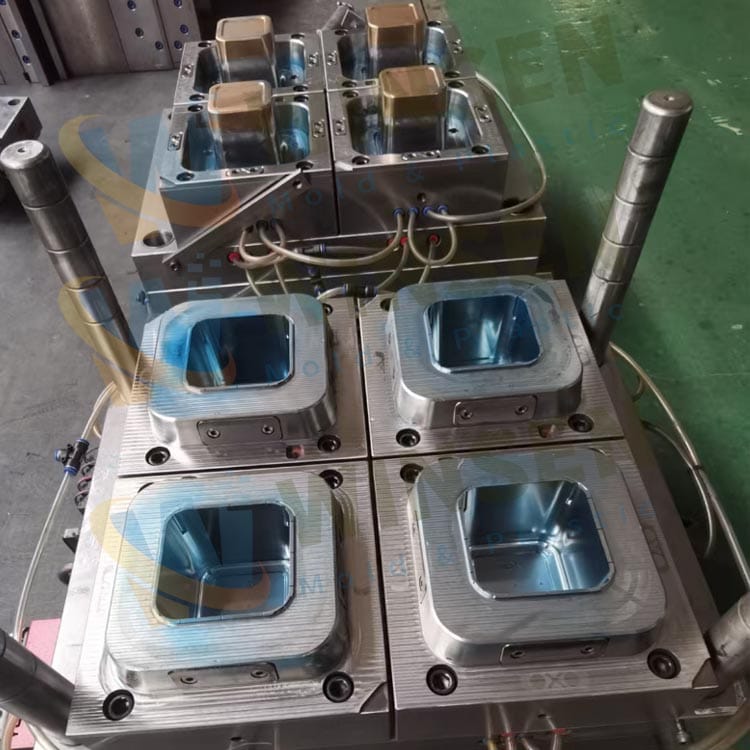

H13 plastic food container injection mold with beryllium bronze core excellent performance.Plastic food containers are popular in the food packaging industry for their lightweight, durable, and cost-effective nature. The production of these containers relies on injection moulding molds, a crucial step. This article will delve into how a high-end plastic food container injection mold—made from H13 material and featuring a beryllium bronze core insert—can improve production efficiency and product quality.

Table of Contents

Toggle

Basic Concepts of Plastic Food Container Injection Molds

Injection molds are tools used to manufacture plastic products. They inject molten plastic into a mold and form it into the desired shape after cooling. Plastic food container injection molds are specifically designed for producing food containers that meet food safety standards and possess excellent sealing and heat resistance.

H13 Food Container Injection Molds Material

- Material Characteristics: H13 is a hot work die steel with excellent toughness, wear resistance, and heat resistance, making it ideal for injection container box mold manufacturing.

- Application Advantages:

High Toughness: H13’s high toughness enables it to withstand the high pressure and impact of the injection molding process.

Heat Resistance: Its excellent heat resistance ensures that the container molds maintains stable shape and dimensions even at high temperatures.

Wear Resistance: H13’s wear resistance extends mold life and reduces plastic container molds replacement frequency.

Beryllium Bronze Core

- Material Properties: Beryllium bronze is a high-strength, high-thermal-conductivity material, making it ideal for injection plastic container box mold cores.

- Application Advantages:

Wear Resistance: Beryllium bronze boasts significantly higher wear resistance than traditional mold materials, extending mold life.

Thermal Conductivity: Excellent thermal conductivity ensures rapid container molds cooling, improving production efficiency.

Corrosion Resistance: Beryllium bronze exhibits excellent corrosion resistance, making it suitable for use in food container production, ensuring product safety.s

Design and Manufacturing food container mould

- Design Phase: During the design phase, the specific requirements of the H13 mold material and the beryllium-inlaid bronze core were considered to ensure optimal mold performance.

- Manufacturing Process: During the manufacturing process, high-precision machining equipment and techniques were used to ensure mold accuracy and durability.

Injection Molding of plastic container box mould

- Raw Material Preparation: Select appropriate plastic raw materials, such as polyethylene (PE) and polypropylene (PP), which are food-safe and heat-resistant.

- Injection Molding Machine Operation: Inject the molten plastic into the mold. The machine controls precisely the injection pressure, speed, and cooling time.

- Cooling and Demolding: After the plastic cools and solidifies in the mold, the finished container is removed from the mold using the demolding system.

Mold Maintenance and Care

Regular Cleaning: To maintain mold cleanliness, clean and disinfect it regularly to prevent the accumulation of food residue.

Wear Inspection: Regularly inspect molds for wear and tear, and promptly repair or replace them to ensure product quality and mold life.

Storage: When not in use, molds should be stored in a dry, well-ventilated environment to avoid moisture and corrosion.

Challenges and Solutions

- Challenge: High-end container moulds require high precision, making deformation and wear a common problem during the production process.

- Solution: Utilize high-precision processing equipment, strengthen mold maintenance, and employ advanced mold design techniques.

Future Development Trends

- Intelligence: With the development of Industry 4.0, mold manufacturing will become more intelligent, improving production efficiency and product quality.

- Environmentally Friendly Materials: With increasing environmental awareness, the use of biodegradable or recyclable plastic materials may increase in the future.

- Versatility: To meet diverse food packaging needs, mold design will place greater emphasis on versatility and flexibility.

The application of the YUDO hot runner system and beryllium-inlaid bronze materials has revolutionized injection container molds for plastic food containers. These advanced technologies not only improve production efficiency and product quality, but also help reduce costs and environmental impact. With the continuous advancement of technology and changing market demands, we have reason to believe that future injection molds will be even more efficient, environmentally friendly, and intelligent, bringing greater possibilities to the food packaging industry.

This article has demonstrated the importance and advantages of the YUDO hot runner system and beryllium-inlaid bronze materials in injection molds for plastic food containers. The application of these technologies not only improves product quality and production efficiency, but also supports the sustainable development of the food packaging industry. With the continuous advancement of technology, we look forward to seeing more innovative mold technologies being developed and applied.