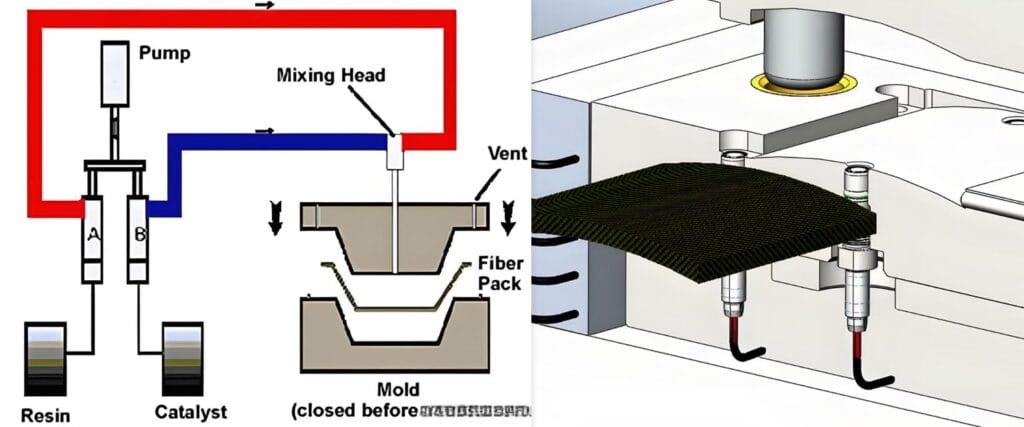

Resin Transfer Molding (RTM) is a process in which resin is injected into a closed mold to impregnate the reinforcing material and then solidify. This technology eliminates the need for prepregs and autoclaves, effectively reducing equipment and molding costs. This technology has developed rapidly in recent years and is increasingly used in the aircraft, automotive, and shipbuilding industries. It has also developed various branches, including RFI, VARTM, SCRIMP, and SPRINT, to meet the application needs of different fields.

Table of Contents

ToggleIn modern manufacturing, composite materials are gaining increasing attention for their lightweight, high-strength, and corrosion-resistant properties. Resin transfer molding (RTM), an advanced composite manufacturing compression molding process, plays a vital role in industries such as automotive, aerospace, and wind energy. This article will delve into the principles, advantages, applications, and future development trends of RTM technology.

History of RTM

Basic Principles Resin transfer moulding Mold

Development Directions of RTM Molding

Technical Features of RTM

The operation process of RTM technology

- Mold Preparation: First, a precision mold is prepared, and the interior surface is coated with a release agent.

- Fiber Placement: Pre-cut fiber reinforcement is laid within the mold to form the desired part shape.

- Resin Infusion: Resin is injected into the mold using an injection system, flowing through the mold and penetrating the fiber layers.

- Curing: The resin solidifies within the mold, forming a strong composite part.

- Demolding: After curing, the part is removed from the mold for subsequent processing and inspection.

Process Equipment of RTM Production

The RTM molding process consists of 11 steps. Operators, tools, and equipment are stationary in each step, and molds are transported by cart through each step, achieving streamlined production. The mold cycle time on the assembly line generally reflects the product’s production cycle. Small products typically take just over ten minutes, while large products can be completed in under an hour.

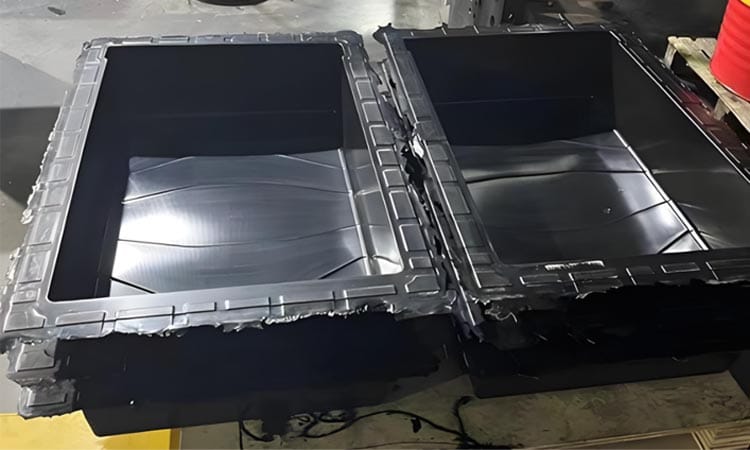

RTM molding equipment primarily consists of a resin injection machine and molds. ① Resin Injection Machine: The resin injection machine consists of a resin pump and an injection gun. The resin pump is a piston-type reciprocating pump with an air-powered pump at the top. When compressed air drives the air pump’s piston up and down, the resin pump pumps a measured amount of resin from the barrel through a flow controller and filter into the resin reservoir. A side lever activates the catalyst pump, pumping a measured amount of catalyst into the reservoir. Compressed air fills both reservoirs, creating a buffering force opposing the pump pressure, ensuring a steady flow of resin and catalyst to the injection gun tip. Behind the injection nozzle is a static turbulent mixer that mixes the resin and catalyst in an airless state before injecting them into the mold. A cleaning agent inlet is located behind the mixer, connected to a solvent tank with a pressure of 0.28 MPa. When the machine is finished using, the switch is turned on, and the solvent automatically sprays out, cleaning the injection nozzle. ② Molds: RTM molds come in three types: fiberglass molds, fiberglass molds with metal coating, and metal molds. Fiberglass molds are easy to manufacture and relatively inexpensive. Polyester fiberglass molds can be used 2,000 times, while epoxy fiberglass molds can be used 4,000 times. Fiberglass molds with metal coating can be used over 10,000 times. Metal molds are rarely used in the RTM process. Generally speaking, the mold cost for RTM is only 2% to 16% of that for SMC.

Challenges and Solutions of RTM Technology

While RTM technology offers many advantages, it also faces practical challenges, such as resin flow control, bubble removal, and cost control. To address these challenges, researchers and engineers are developing new materials, improving processes, and optimizing designs.

Future Development Trends

With increasingly stringent environmental regulations and the growing demand for lightweight components, RTM technology will see wider applications in the future. It is expected that RTM technology will become more intelligent and automated, improving production efficiency and reducing costs.

Conclusion

Resin transfer molding (RTM) is a highly efficient and environmentally friendly composite material manufacturing process with broad application prospects across multiple industries. With continued technological advancement and innovation, RTM is expected to play a greater role in the manufacturing industry, driving lightweighting and sustainable development trends.