Fiber Reinforced Polymer (FRP) custom molds have revolutionized the manufacturing industry by offering a versatile, cost-effective, and durable solution for producing complex shapes and designs. In this blog, we will explore the world of FRP custom compression molds, their applications, benefits, and how they are shaping the future of mold making.

Table of Contents

ToggleFRP custom molds are specialized tools used in the manufacturing process to give materials a desired shape or form. They are made from a composite material that combines fibers with a polymer matrix. The fibers provide strength and rigidity, while the polymer matrix offers flexibility and durability. FRP molds can be tailored to fit the specific requirements of a project, making them ideal for producing one-of-a-kind parts and components.

What are FRP Custom Molds?

FRP custom molds are specialized tools used in the manufacturing process fiberglass molding to give materials a desired shape or form. They are made from a composite material that combines fibers with a polymer matrix. The fibers provide strength and rigidity, while the polymer matrix offers flexibility and durability. FRP molds can be tailored to fit the specific requirements of a project, making them ideal for producing one-of-a-kind parts and components.

FRP custom molds are more than just ancillary tools; they are enablers of innovation, bridging the gap between design concepts and tangible products. By mastering their design, materials, and processes, manufacturers can achieve new levels of precision, efficiency, and sustainability. As technology advances, the role of custom molds will only grow—propelling the next wave of breakthroughs in composite manufacturing.

Whether you’re prototyping a consumer product or scaling up an industrial solution, investing in high-quality FRP custom molds isn’t just a technical choice—it’s a strategic one.

Applications of FRP Custom Molds

The versatility of FRP custom molds makes them suitable for a wide range of applications across various industries. Some of the most common uses include:

- Aerospace Industry: FRP molds are used to create lightweight and strong components for aircraft, such as wings, fuselages, and engine parts.

- Automotive Industry: They are employed in the production of car parts, including body panels, spoilers, and interior components, to reduce weight and improve fuel efficiency.

- Marine Industry: FRP molds are used to manufacture boat hulls, decks, and other marine structures that require resistance to corrosion and marine environments.

Construction Industry: They are utilized for creating architectural elements, such as facades, cladding, and decorative pieces, that offer both aesthetic appeal and durability. - Sports Equipment: FRP molds are used to produce high-performance sports equipment, like surfboards, kayaks, and bicycles, which demand lightweight and strong materials.

Benefits of FRP Custom Molds

FRP custom molds offer several advantages over traditional mold materials, such as metal or wood. Here are some of the key benefits:

- Cost-Effectiveness: FRP molds are generally more affordable to produce than metal molds, especially for small production runs or complex designs.

- Lightweight: The composite nature of FRP materials makes the molds lighter, which can reduce transportation costs and handling requirements.

- Durability: FRP molds are resistant to corrosion, chemicals, and UV radiation, ensuring a longer lifespan compared to metal or wood molds.

- Flexibility: FRP molds can be designed to accommodate complex geometries and intricate details, making them suitable for producing parts with unique shapes and designs.

- Sustainability: The use of FRP materials in mold making can contribute to a more sustainable manufacturing process due to their recyclability and reduced environmental impact.

- Fast Production: FRP molds can be produced more quickly than metal molds, allowing for faster turnaround times and reduced lead times for production.

How FRP Custom Molds are Made

The process of creating an FRP custom mold involves several steps:

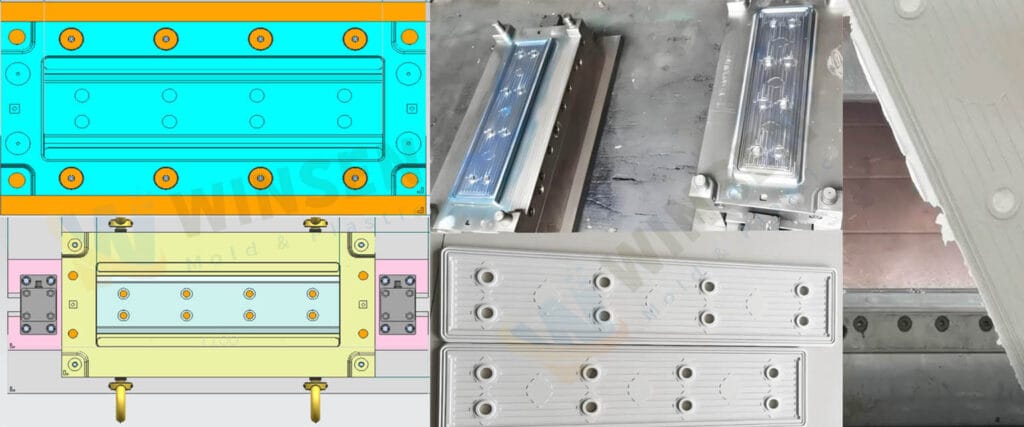

- Design: The first step is to design the mold based on the specific requirements of the project. This includes creating a detailed blueprint of the mold’s shape, size, and dimensions.

- Mold Construction: Once the design is finalized, the mold is constructed using a combination of fiberglass and resin. The fiberglass provides the strength and rigidity, while the resin acts as a binder to hold the fibers together.

- Curing: After the mold is constructed, it is placed in an oven or autoclave to cure. This process hardens the resin and strengthens the mold, ensuring it is ready for use.

- Finishing: Once the mold is cured, it is sanded and polished to achieve a smooth, finished surface. This is important for ensuring the quality of the final product.

- Testing: Before the mold is used in production, it is tested to ensure it meets the required specifications and can produce the desired parts accurately and consistently.

The Future of FRP Custom Molds

As technology continues to advance, the use of FRP custom molds is expected to grow in popularity. Here are some trends and developments that are likely to shape the future of FRP mold making:

- 3D Printing: The integration of 3D printing technology in the creation of FRP molds can lead to even greater precision and customization, allowing for the production of more complex and intricate designs.

- Automated Production: The use of automated production techniques can increase the efficiency and consistency of FRP mold making, reducing the time and labor required to produce high-quality molds.

- Advanced Materials: The development of new materials and composites can further enhance the properties of FRP molds, making them even stronger, more durable, and better suited to specific applications.

- Digital Manufacturing: The rise of digital manufacturing technologies can streamline the design and production process of FRP molds, making it easier and more cost-effective to create custom molds for a wide range of applications.

- Sustainability Initiatives: As the focus on sustainability grows, there will be a greater emphasis on using eco-friendly materials and processes in FRP mold making, reducing the environmental impact of manufacturing.

Challenges and Solutions in FRP Mold Manufacturing

Despite their advantages, FRP custom molds face challenges like bubble formation, warping, and limited lifespan. Here’s how to address them:

| Challenge | Cause | Solution |

|---|---|---|

| Bubbles/Voids | High resin viscosity or improper layup | Vacuum degassing and controlled roller pressure. |

| Gelcoat Cracking | Excessive thickness | Limit gelcoat to 0.6mm and apply in multiple layers. |

| Dimensional Instability | Rapid curing or low-quality materials | Use low-shrinkage resins and post-cure molds gradually. |

The Future: Where FRP Custom Molds Are Headed

As industries demand lighter, stronger, and more sustainable composites, FRP custom molds will continue to adapt. Expect to see:

- AI-Driven Design: Generative algorithms optimizing mold geometry for weight and performance.

- Circular Materials: Molds made from recycled composites or bio-resins.

- Hybrid Processes: Combining additive manufacturing with traditional layup for faster turnaround.

Conclusion

FRP custom molds represent a significant advancement in the field of mold making, offering a range of benefits that make them an attractive option for manufacturers across various industries. As technology continues to evolve, the capabilities and applications of FRP molds are likely to expand, further solidifying their role in the future of manufacturing. Whether you are a small business owner looking to produce unique parts or a large-scale manufacturer seeking to improve efficiency and reduce costs, FRP custom molds offer a versatile and effective solution for your mold making needs.

By embracing the advantages of FRP custom molds and staying informed about the latest trends and developments, manufacturers can position themselves at the forefront of innovation and competitiveness in today’s rapidly changing market.