Table of Contents

ToggleWhat Is SMC Composite Fiberglass Compression?

SMC composite fiberglass compression is a high-pressure, high-temperature molding process that converts Sheet Molding Compound (glass-fiber mat + unsaturated resin + fillers) into lightweight, high-strength, corrosion-free parts in under 2 minutes. Compared to steel or aluminum, it offers 30 % weight savings, Class-A surface, and 10 k-hour salt-spray resistance, making it ideal for automotive body panels, electrical enclosures, and architectural façades.

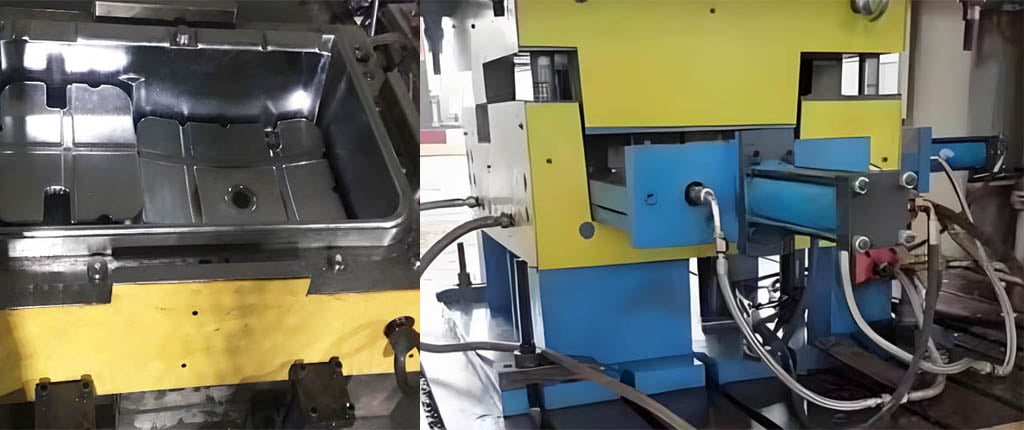

How Does SMC Compression Work?

- Pre-weighed SMC sheet is laid into the heated mold (135–160 °C).

- Hydraulic press closes at 15–30 MPa, forcing resin to flow and fill the cavity.

- Chemical cross-link cures the part in 60–90 seconds.

- Mold opens; part is demolded, trimmed, and ready for paint or assembly.

Key Properties of SMC Composite

- Density: 1.75–1.95 g/cm³ (≈30 % lighter than aluminum)

- Tensile strength: 150–200 MPa

- Flexural modulus: 10–12 GPa

- UL-94: V-0 @ 1.5 mm natively

- Thermal endurance: −40 °C to 150 °C continuous

Cost vs. Metals

Per kg SMC material is cheaper than aluminum sheet and eliminates welding, surface primer, and corrosion coating, cutting total part cost by 15–25 % for volumes above 5 k/yr.

Common Applications

- Automotive: tailgates, fenders, battery trays, front-end modules

- Electrical: medium-voltage breaker boxes, meter housings, EV charger shells

- Building: cladding panels, cable trays, decorative façades