Compression Molding Demystified: Steps, Purpose, Process and Top Benefits

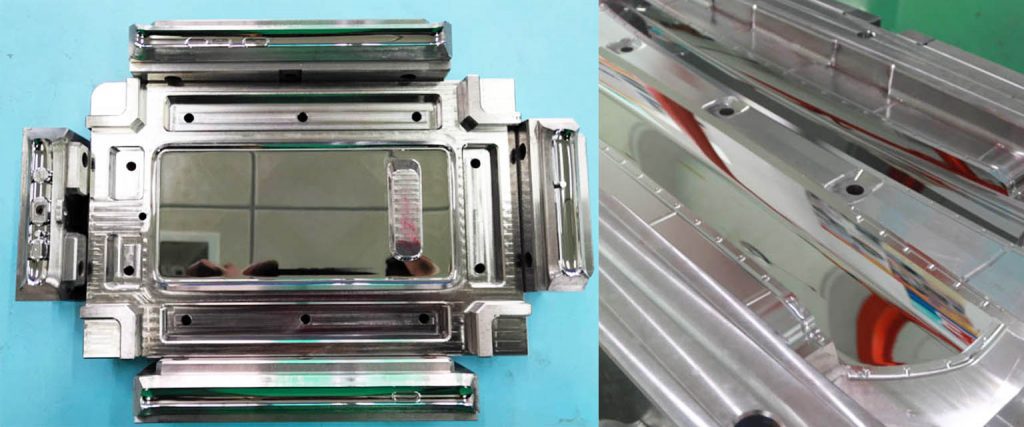

A compression mold is a two-part tool—cavity and core—into which pre-weighed, pre-heated raw material is loaded; under high pressure it flows, fills and cures, producing robust FRP or plastic components for cars, electronics and consumer products.

Table of Contents

ToggleWhat Is Compression Molding?

Compression molding is a heat-and-pressure technique that forces thermoset or thermoplastic compounds into a closed cavity, where they soften, flow and cure into uniform, high-strength parts. The simultaneous heat and pressure trigger a chemical cross-linking reaction, giving the finished shape its final mechanical properties. First patented in 1905, the method has outlived countless technological shifts and remains a trusted route for producing everything from dental instruments to gaming controllers. Upcoming sections detail how the process works, where it is applied, and why engineers still choose it over alternative forming technologies.

Why Is Compression Molding So Critical Today?

Compression molding turns pre-impregnated intermediates into load-bearing composite parts, whether the matrix is thermoset or thermoplastic. It offers thick-wall capability, minimal scrap, and high-volume output, making it the go-to route for cost-effective, large-surface structural components.

How Compression Molding Works

- Tool Preparation – Steel or aluminium mould halves are cleaned, assembled and pre-heated to the target temperature to avoid warping.

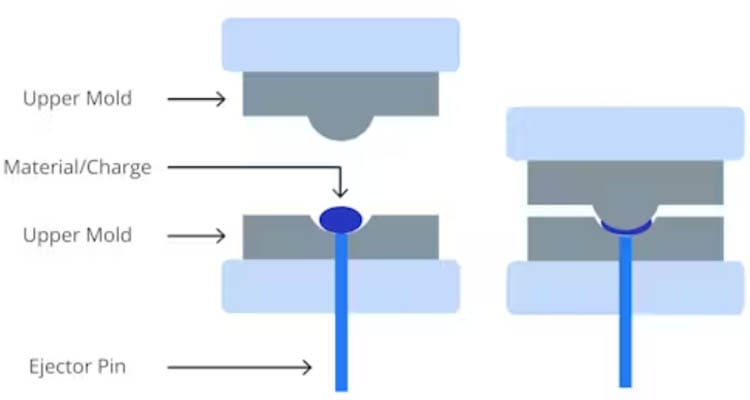

- Charge Placement – A pre-weighed charge of fibre-reinforced thermoset (or thermoplastic compound) is laid in the lower cavity; for thermoplastics, the tool is cooled rather than heated.

- Closure & Cure – The upper half descends, locking in pressure, heat and speed settings; material flows, fills and cross-links (or cools) within 1–5 minutes depending on wall thickness.

- Demould & Trim – The press opens, the part is ejected, and excess flash is removed—ready for assembly without further curing.

What’s the Typical Cycle Time for Compression Molding?

Compression molding cycle time is driven by wall thickness, but most thermoset parts cure in 60–300 seconds, keeping the process among the fastest FRP routes available.

What Equipments Are needed in Compression Molding?

- Hydraulic Press: Typically ranging from 150 to 2,500 tons, this equipment applies the necessary clamping force.

- Mold: Comprising an upper and lower half, along with an internal cavity, it directs material flow during the melting and reshaping phase.

- Heating Chamber: Utilized to elevate material temperature, achieving the molten state.

- Heating Elements: Long, cylindrical resistors that serve as the primary source of heat.

- Air Blower: Assists in cavity cleaning, removing debris, particles, and contaminants from various machine components.

- Trimming Tools: Manually used to remove excess material post demoulding.

How Does Compression Molding Transform Material?

Compression molding utilizes the application of heat and pressure to reshape a pliable material pre-form into the desired configuration. The process entails compressing the charge between the two halves of a heated mold, causing the material to conform to the mold’s cavity as it cools or cures.

What Materials Are Involved in Compression Molding?

- Epoxy Resin Epoxy resins are renowned for their excellent mechanical properties, high heat resistance, and dimensional stability. Combined with reinforcing materials like glass or carbon fiber, they form high-performance composites. This makes them ideal for aerospace parts, electrical insulation, and structural composites.

- Silicone Silicone is valued for its superior heat resistance, flexibility, and suitability for electrical insulation. It flows easily into the cavity and can be molded into intricate shapes, making it perfect for precision seals, gaskets, medical devices, and automotive components.

- Melamine Melamine resins provide outstanding heat resistance, hardness, and chemical resistance, making them suitable for compression molding. They mold easily and produce finished parts with excellent surface finishes and dimensional stability. Commonly used in compression molding for kitchenware, decorative laminates, electrical components, and heat-resistant utensils.

- Urethane Urethane, or polyurethane materials are preferred in compression molding for their exceptional toughness, abrasion resistance, and impact strength. They can be formulated to exhibit a wide range of physical properties, making them versatile for various applications. Urethane flows well during compression molding, allowing for intricate mold designs and the production of items such as automotive parts, rollers, wheels, and industrial seals.

- High-Density Polyethylene (HDPE) This type of plastic is ideal for melting and molding. It offers fantastic chemical resistance, strength, and rigidity. Moreover, it can handle significant impacts, which is why it’s used for automotive components and industrial parts.

- Polyphenylene Sulfide (PPS) For electrical components, industrial equipment, and some automotive parts, manufacturers often use PPS. This is because it flows well once it’s melted down but cools into a stiff yet strong finish.

- Polytetrafluoroethylene (PTFE) You’ll likely recognize this material in the kitchen as it’s used to create non-stick surfaces. In compression molding it offers much of the same benefits—stability in high temperatures, chemical resistance, and a slick surface.

What Industries Benefit from Compression Molding?

- Kitchenware Compression molding is instrumental in producing kitchen essentials like bowls, cups, plates, and utensils, creating heat-resistant and durable versions suitable for outdoor dining.

- Automotive Components Compression molding is employed to fabricate both minor and major vehicle parts, including door panels, dashboards, and engine components for cars, trucks, and tractors.

- Electrical Components Utilizing the materials mentioned, compression molding is well-suited for crafting electrical parts, offering manufacturers precision, reliability, and consistency in their designs.

- Gaming and Computing Devices Compression molding plays a crucial role in the creation of devices we use daily, such as computer keyboards, gaming controllers, and electrically insulated parts for various gadgets.

- Medical and Dental Equipment Compression molding enables the production of intricate plastic and silicone parts essential for medical and dental practices, like syringe stoppers and respirator mask components.

What Quality Does Compression Molding Achieve?

Do Compression Molding Products Last Long?

Is Compression Molding a Safe Manufacturing Method?

Is There a Growing Need for Compression Molding?

How Long-Lasting are Compression Molded Products?

What's the Outlook for Compression Molding?

Machine learning, AI, and automation are streamlining the compression molding process. As the demand for compression molded products continues to grow, so too do the materials that can be utilized in these machines. With the ease of manufacturing everyday items like dishes and more sophisticated components for computers, it’s challenging to envision this manufacturing process slowing down in the near future.

What Benefits Does Compression Molding Offer?

- It produces parts with exceptional strength that withstand significant wear and tear, suitable for heavy-duty applications.

- Molds are highly customizable, allowing for the creation of intricate designs or simpler forms.

- The process is versatile, accommodating a variety of materials, including those that are highly sensitive, enabling the production of a broad spectrum of products.

- It’s material-efficient, leading to cost savings over time.

- Parts exhibit superior surface finishes.

- Enables batch production, with settings and cycles optimized for peak efficiency.

- Utilizes recycled and eco-friendly materials, appealing to environmentally conscious businesses.

What Drawbacks Does Compression Molding Have?

- While it can handle complex parts, creating intricate components with thin walls is challenging.

- Limited pressure range restricts the creation of finely detailed shapes.

- Though quick, it’s slower than processes like injection molding.

- The heat, pressure, and cooling cycle can result in extended production times.

- Flashing may occur, leading to imperfect parts, material waste, and resource loss.

The Prospects of Compression Molding

How Do Compression Molding and Injection Molding Compare?

How Do Compression Molding and Injection Molding Compare?

How Can WS MOLD Assist You?

- Note