SMC Fiberglass Compression Mold: The Complete Guide to Process, Benefits, Design Tips, and Future Trends

SMC fiberglass compression mold is a heated closed-mold process that cures sheet molding compound into lightweight, high-strength composite parts within 30 seconds to 5 minutes.

Key Points

- Uses 10–60 % glass fiber reinforced polyester sheets

- Mold temperature: 135–160 °C

- Pressure: 1 000–3 000 psi (7–20 MPa)

- Cycle time: 30 s–5 min depending on thickness

- Linear shrinkage ≤ 0.1 %

Typical Parameters

| Parameter | Value |

|---|---|

| Glass fiber content | 25–55 wt % |

| Mold temperature | 140 ± 5 °C |

| Curing pressure | 10 MPa |

| Cure time @ 3 mm | 60 s |

Detailed Process Description

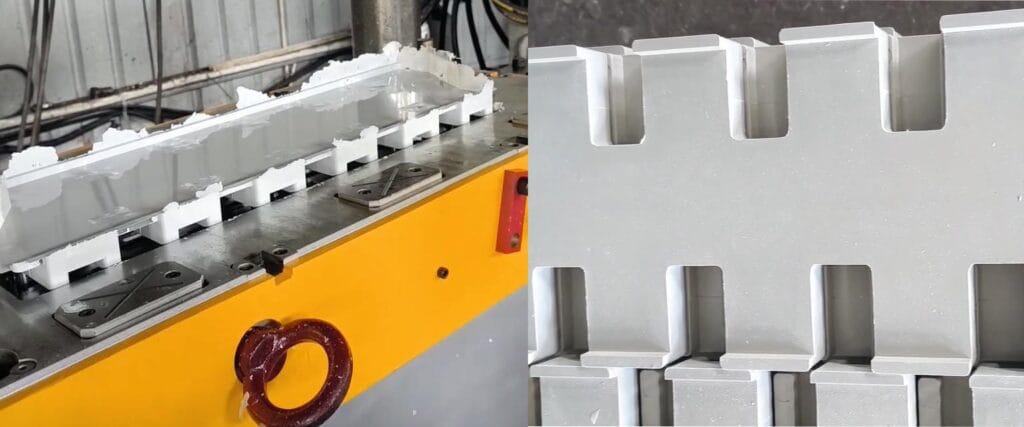

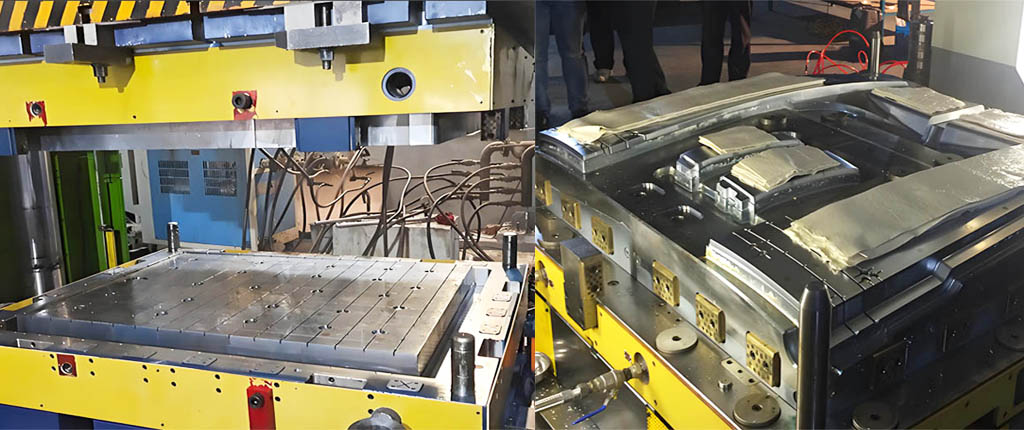

Sheet molding compound (SMC) is a ready-made sheet composed of chopped glass fibers, unsaturated polyester resin, mineral fillers, and additives. After 24–48 h maturation, the sheet is cut to a predetermined weight (±2 %) and placed into a pre-heated steel mold. A hydraulic press closes at 5–60 mm s⁻¹, applying heat and pressure to initiate cross-linking. The exothermic reaction peaks at 180–200 °C inside the part, after which the mold opens and ejector pins remove the cured component. Post-mold cooling fixtures maintain dimensional stability while the temperature drops below 80 °C. Finally, cryogenic tumbling or robotic routing removes residual flash, yielding a net-shape part with excellent surface finish.

Advantages Over Alternative Processes

- Higher glass loading than RTM or hand lay-up → superior stiffness-to-weight

- Class A surface straight from the mold → eliminates primer surfacer

- Labor content 70 % lower than open-mold laminating

- Consistent wall thickness ±0.1 mm → reduced post-machining

- Excellent corrosion resistance → ideal for automotive under-body and electrical enclosures

Tooling Design Guidelines

Production molds are usually machined from P20 or H13 steel and hardened to 45–50 HRC for runs exceeding 100 000 shots. Draft angles should be ≥1° to ensure easy release; shear edges are machined to 0.05–0.10 mm clearance for clean flashing. Uniform wall thickness (2–4 mm) minimizes flow lines, while integrated vacuum channels (<50 mbar) help evacuate trapped air and reduce voids. Locating holes or datum pads should be included for post-mold machining alignment.

Recent Innovations

- Low-density SMC: Hollow glass microspheres cut density to 1.2 g cm⁻³ while maintaining 200 MPa flexural strength.

- Conductive SMC: Carbon nanotubes provide EMI shielding for EV battery covers.

- In-mold coatings: Polyurethane clear coat cured in-press eliminates paint lines.

- Hybrid molding: Local continuous carbon fiber patches for tailored stiffness.

- Simulation accuracy: Moldex3D and Sigmasoft predict weld lines within 5 %, cutting trial iterations by 30 %.

Sustainability Outlook

Although SMC is a thermoset, glass-rich residues can be milled into 0.5 mm powder and reused as filler (up to 20 %) without mechanical penalty. Solvolysis recovers styrene-free resin oligomers for use as concrete additives, and major OEMs have committed to 25 % recycled content in SMC fiberglass compression mold parts by 2030.

Conclusion

SMC fiberglass compression mold delivers net-shape, high-strength, and aesthetically superior composite parts at automotive production rates. By mastering charge design, tooling details, and cycle optimization, manufacturers can exploit its low labor cost and excellent property-to-weight ratio while meeting tight sustainability targets. Whether you are specifying materials for an EV battery housing, a truck cab roof, or an electrical enclosure, SMC fiberglass compression mold deserves a front-line position in your process portfolio.