Compression Molds to Slovenia: 20+ Years of Expertise

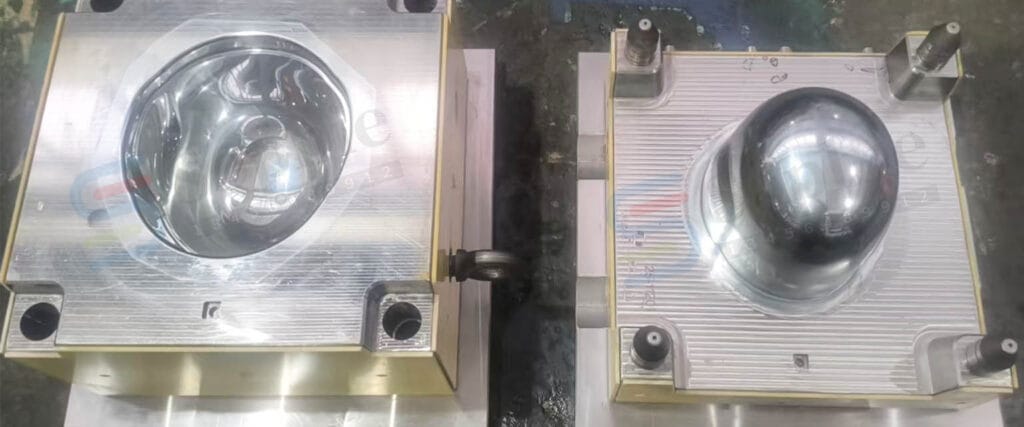

In the world of protective gear, helmets play a crucial role in ensuring safety across various industries and sports. At our company, we have dedicated over two decades to perfecting the art and science of compression molding, particularly for producing high-quality Kevlar (Aramid) and UHMWPE (Ultra-high molecular weight polyethylene) helmets. We recently produced a bulletproof helmet mold for a Slovenian client.As we expand our reach to the Slovenia market, we are excited to bring our expertise and craftsmanship to a new audience in ballistic helmet molds industry.

Table of Contents

Toggle

Compression helmets are helmets formed through a molding process. This process typically involves placing materials into a heated mold and curing them under high temperature and pressure to achieve a high-strength, lightweight structure. Molding technology is widely used in riot control, bulletproofing, and sports protection. Common materials include ultra-high molecular weight polyethylene, polycarbonate, fiberglass, and Kevlar/Aramid.

Our Expertise in Compression Molding

This bulletproof helmet mold uses compression molding technology to produce Kevlar/aramid and UHMWPE Helmet bulletproof helmets.

Compression molding is a precision-driven process that requires meticulous attention to detail and a deep understanding of materials and machinery. Over the past twenty years, we have honed our skills in this field, becoming a leading manufacturer of compression molds for protective helmets. Our journey has been marked by continuous innovation, rigorous quality control, and a commitment to delivering products that meet the highest standards of safety and durability.

Innovative mold technology improves production efficiency by 10-15%

Every year, we explore and innovate with the latest technologies. Currently, we use the latest technology to design mold structures, which increases mold production efficiency by 10-15% compared to ordinary production. This greatly helps companies improve production efficiency, save costs, and quickly capture market share.

Precision Engineering for Safety

When it comes to manufacturing helmets, precision is not just a buzzword—it’s a necessity. Our compression molds are engineered with state-of-the-art technology to ensure that every helmet produced meets stringent safety regulations. Whether it’s a Kevlar helmet for military or law enforcement use or a UHMWPE helmet for sports and industrial applications, our molds are designed to create helmets with consistent thickness, uniform strength, and optimal fit.

We understand that different industries and sports have unique requirements for helmets. That’s why our compression molds are highly customizable. Our team of engineers works closely with clients to understand their specific needs and design molds that cater to those requirements. From the shape and size of the helmet to the material composition, we ensure that every detail is tailored to provide the best possible protection.

Customization for Diverse Needs

We understand that different industries and sports have unique requirements for helmets. That’s why our compression molds are highly customizable. Our team of engineers works closely with clients to understand their specific needs and design molds that cater to those requirements. From the shape and size of the helmet to the material composition, we ensure that every detail is tailored to provide the best possible protection.

Sustainable and Efficient Production

Case Studies and Success Stories

WS Mold is a notable example of a company that successfully exports compression molds to Armenia,especially military product compression molds, which are well-received in the Armenian market. Their success can be attributed to a combination of high product quality, effective marketing strategies, and strong local partnerships.

Expanding to the Slovenia Market

As we set our sights on the Slovenia market, we are eager to share our expertise with local businesses and industries. Slovenia, with its growing focus on safety and innovation, presents a unique opportunity for us to collaborate and contribute to the development of high-quality protective gear. We are confident that our experience and commitment to excellence will make a significant impact in this new market.

Conclusion

At our company, we take pride in our twenty-plus years of experience in compression molding for Kevlar and UHMWPE helmets. Our dedication to precision, customization, and sustainability sets us apart in the industry. As we embark on this new chapter in Slovenia, we look forward to forging strong partnerships and delivering products that enhance safety and performance. Whether you are a manufacturer looking for reliable molds or an industry seeking top-notch protective gear, we are here to meet your needs with the expertise and passion that define our brand.