The aerospace industry demands injection Mold with precision, durability, and lightweight performance from every component—especially plastic injection-molded parts. However, traditional mold-making methods often struggle with complex geometries, high-temperature materials, and stringent certification requirements, leading to costly delays and compromised quality.

Table of Contents

ToggleThis blog explores how custom aerospace mold solutions—leveraging advanced coatings, 3D printing, and hybrid manufacturing—can overcome these challenges, ensuring faster production, superior part quality, and compliance with aviation standards.

WS aviation injection mold customization manufacturer is your best choice to solve the problems of aviation injection molding parts. We are committed to solving every pain point of aviation injection molding parts with professional, efficient and reliable services. We believe that through our efforts, every customer can find a satisfactory aviation injection mold solution in Fanshida and jointly promote the high-quality development of the aviation manufacturing industry. Choose WS Aviation Mold Customization Official Website to make your aviation project take off easily!

The Critical Challenges in Aerospace Injection Molding

High-Temperature & High-Stress Materials

Aerospace components often use PEEK, PEI (ULTEM), and carbon-fiber-reinforced thermoplastics, which require molds to withstand 300–400°F (150–200°C) without warping or degradation. Traditional steel molds may require frequent maintenance, while aluminum molds wear out quickly.

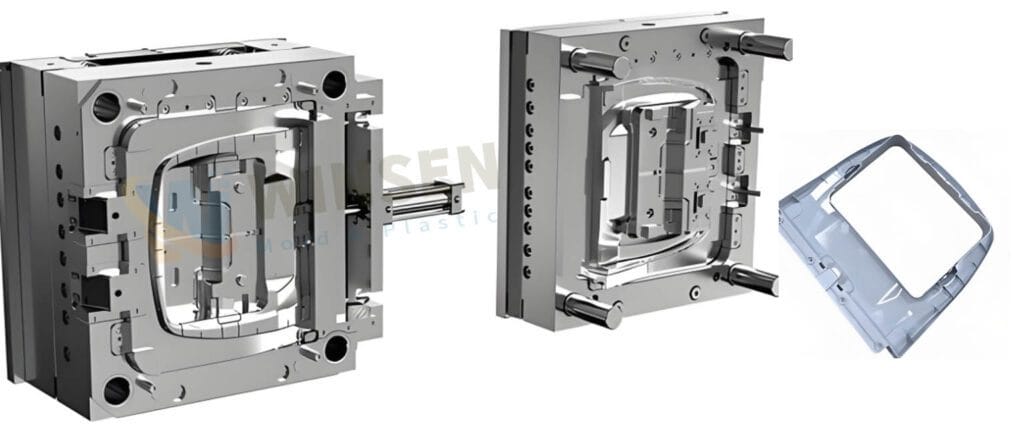

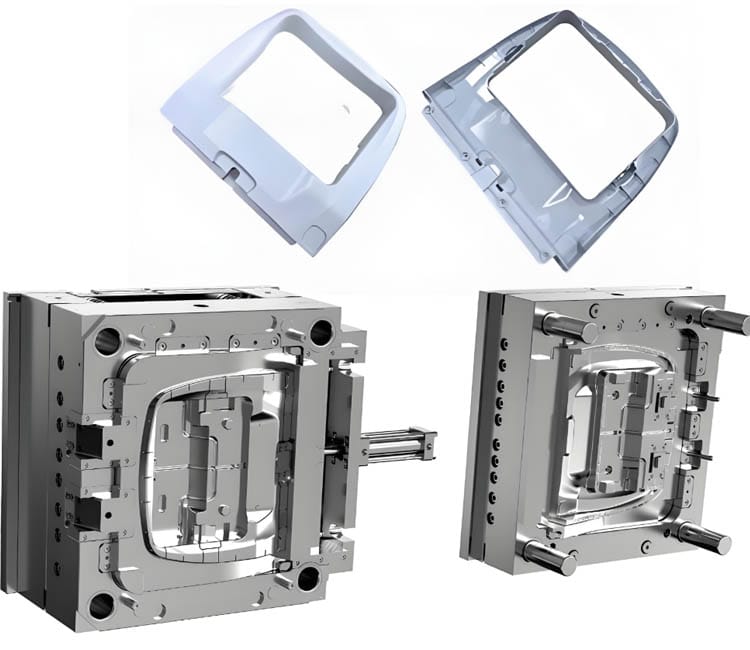

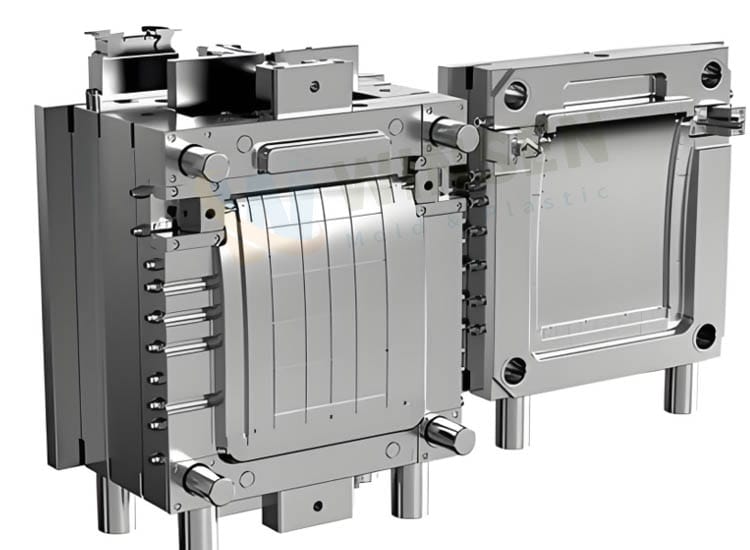

Complex Geometries & Thin-Wall Structures

From aircraft interior panels to drone housings, many aerospace parts feature intricate ribs, undercuts, and ultra-thin walls (0.5–1mm). Conventional CNC-machined molds struggle with these designs, leading to ejection failures, sink marks, and inconsistent tolerances

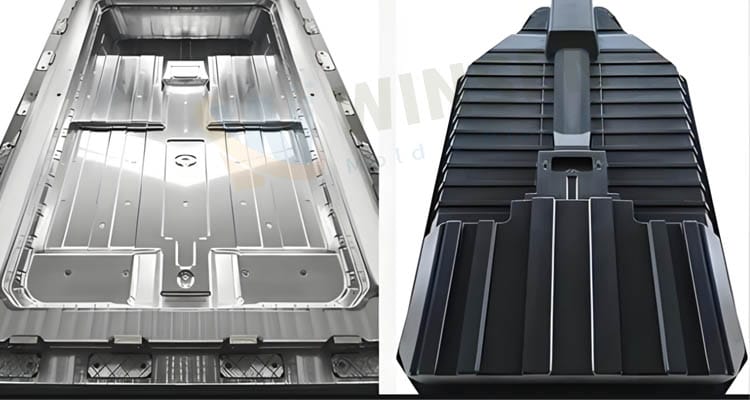

Custom Aerospace Mold Solutions

WS2-Coated Molds for Zero Sticking & Longer Life

WS2 (Tungsten Disulfide) coating bonds permanently to mold surfaces, reducing friction to 0.03 (vs. 0.1–0.3 for steel).

Eliminates release agents, preventing contamination in medical-grade or cabin components.

Case Study: A helicopter parts supplier reduced ejector pin failures by 90% after switching to WS2-coated molds

3D-Printed Composite Molds for Rapid Prototyping

Carbon-fiber-reinforced PSU/PEKK molds can be 3D-printed in days (vs. weeks for metal molds).

Thermwood’s LSAM system combines large-scale 3D printing + CNC machining, producing molds up to 10×20 ft for aircraft interiors.

Cost Savings: Up to 34% cheaper materials + 69% faster production vs. traditional tooling

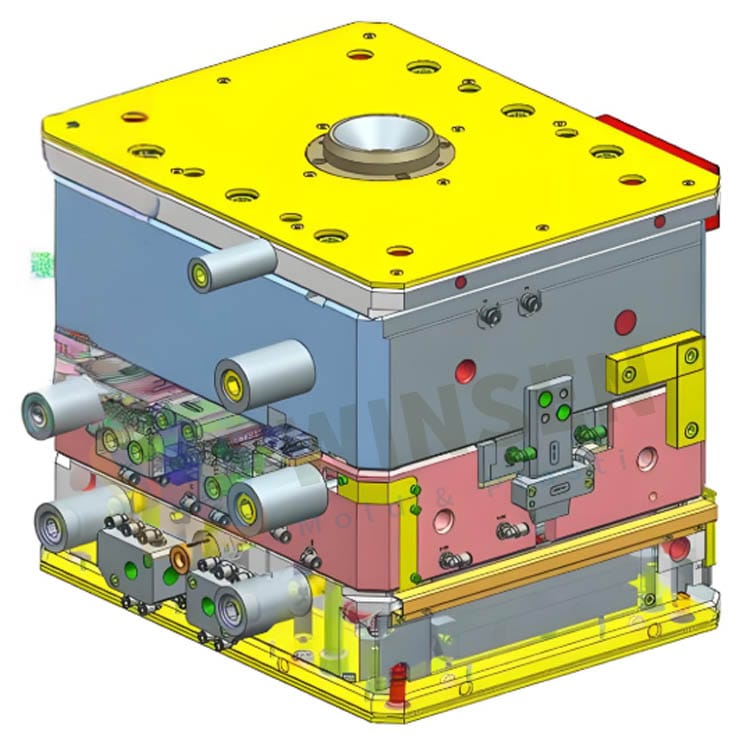

Hybrid Manufacturing for High-Volume Production

Metal 3D-printed inserts (e.g., conformal cooling channels) reduce cycle time by 20–30%.

Modular mold systems allow quick changes for different aircraft part variants.

Industry Applications

| Component | Challenge | Custom Solution |

|---|---|---|

| Cabin Panels | Warping in high-temp environments | PEEK-compatible 3D-printed molds |

| Drone Frames | Thin-wall breakage | WS2-coated molds for smooth ejection |

| Engine Covers | High-pressure resin infusion | Steel molds with conformal cooling |

| Interior Trim | Aesthetic defects (sink marks) | High-precision CNC + polishing |

How to Implement Custom Aerospace Molds

Material Selection – Match mold material (steel, aluminum, or composite) to part requirements.

Design for Manufacturability (DFM) – Optimize draft angles, wall thickness, and gate locations.

Advanced Coatings – Apply WS2 or DLC (Diamond-Like Carbon) for wear resistance.

Testing & Validation – Use CAE simulation to predict filling behavior and stress points.

Why Choose Custom Aerospace Molds?

✔ Faster Time-to-Market – 3D-printed molds cut lead times from 8 weeks to 1 week10.

✔ Lower Costs – WS2 coatings reduce maintenance by 3x1.

✔ Regulatory Compliance – Avoid oil contamination and ensure repeatability.

Carefully select materials to ensure the performance of injection molded parts

Aviation injection molded parts need to maintain stable performance in extreme environments, so the requirements for materials are extremely stringent. WS Injection Mold Factory has established long-term cooperative relationships with many well-known material suppliers and can accurately select injection molding materials suitable for aviation applications according to customer needs. Whether it is high-temperature and corrosion-resistant special plastics or high-strength and lightweight composite materials, we can ensure that the performance of the materials perfectly matches the requirements of aviation injection molded parts. In addition, our mold design team will also optimize the mold structure according to the material characteristics to further improve the performance and service life of injection molded parts.

Fast delivery to meet urgent project needs

The time node of aviation projects is critical, and any delay may result in significant losses. WS Injection Mold Factory is well aware of this, so we have established an efficient production management system. From project contact to mold delivery, every link has been carefully optimized to ensure a quick response to customer needs. Our aviation mold customization official website provides a convenient online communication channel. Customers can communicate with our professional team at any time about the project progress. We promise to complete high-quality mold delivery in the shortest time to help customers’ aviation projects advance on time.

In the field of aviation manufacturing, the quality and precision of injection molded parts are the key to ensuring flight safety and performance. However, many customers often face many pain points when looking for aviation injection molds: complex structural design is difficult to achieve, material performance requirements are stringent, precision requirements are extremely high, and delivery time is tight… These problems make traditional mold solutions seem inadequate and make it impossible to meet customer needs. WS Injection Mold Manufacturer, as a professional aviation mold customization factory, is committed to tailoring accurate, efficient, and reliable aviation injection molds for each customer to solve customers’ urgent needs.