Carbon Fiber Mold: Revolutionizing Manufacturing High-Performance Tooling

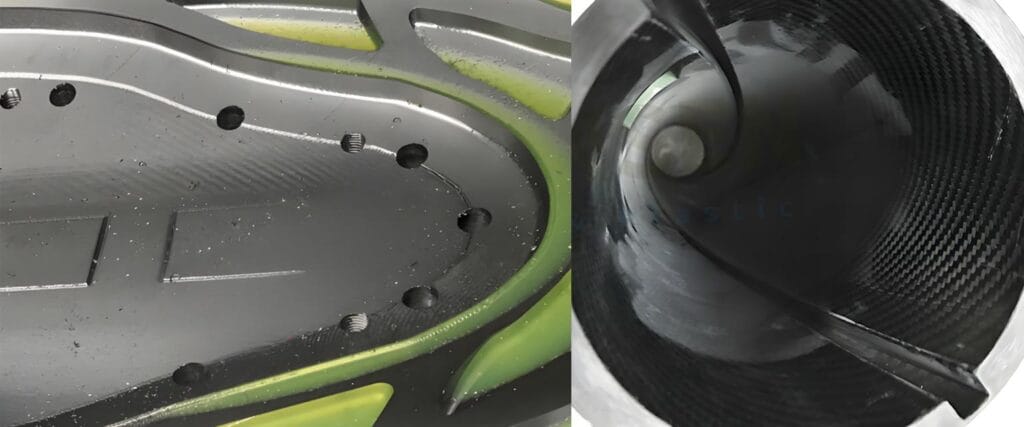

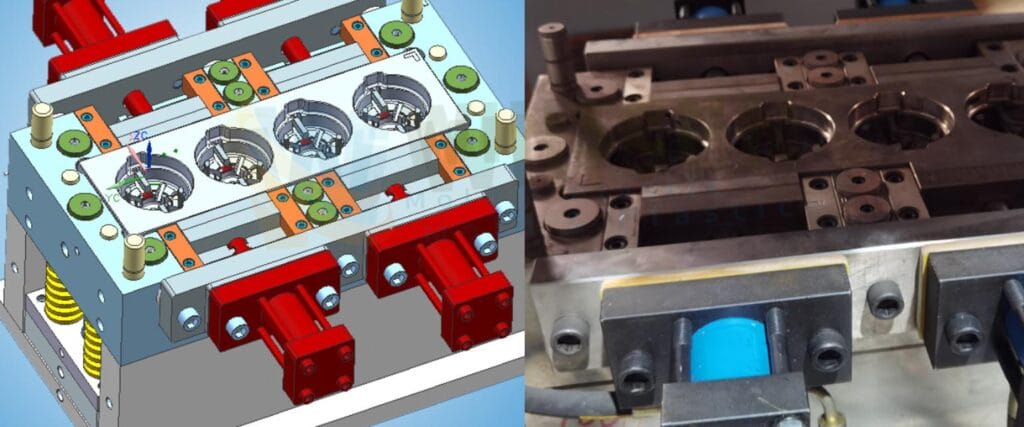

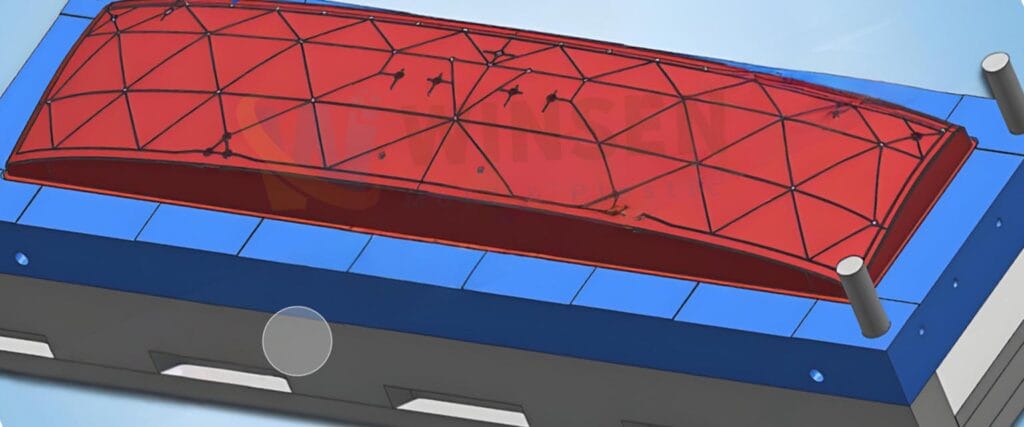

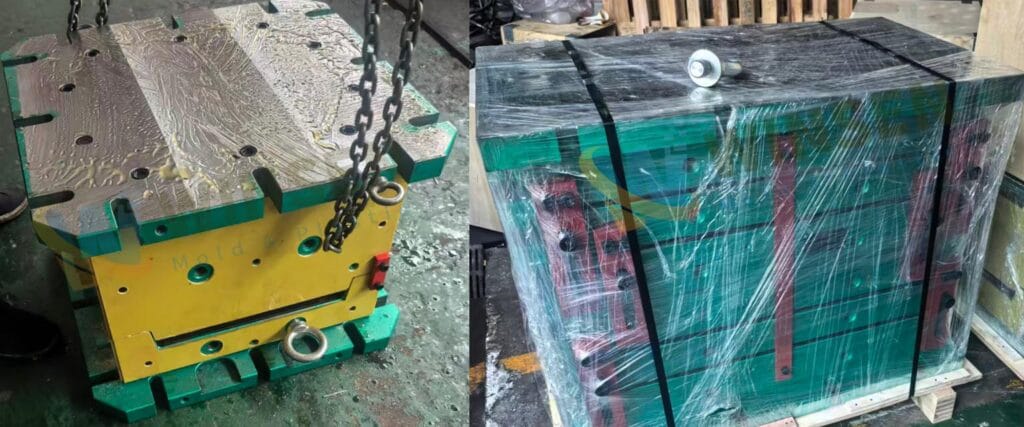

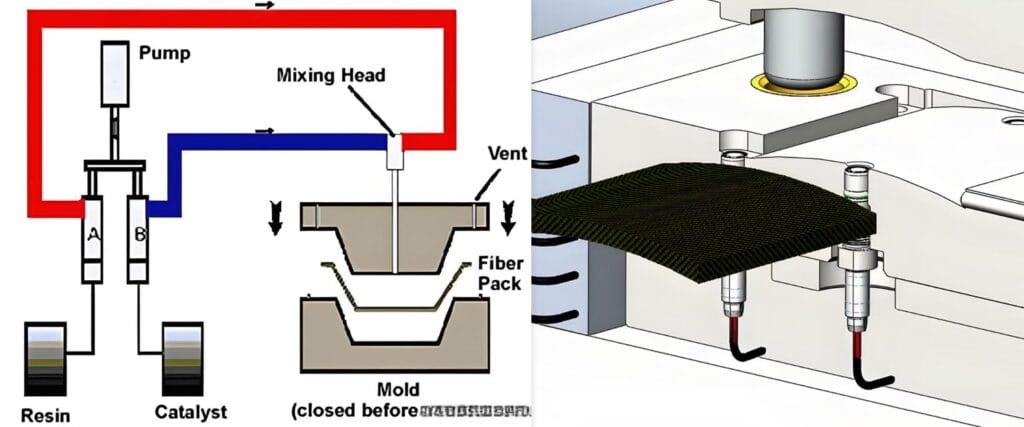

Carbon fiber molds are tooling systems made from carbon fiber composites. These molds leverage the unique properties of carbon fiber, such as high stiffness, low thermal expansion, and excellent dimensional stability, to produce parts with high precision and repeatability.

Carbon Fiber Mold: Revolutionizing Manufacturing High-Performance Tooling Read More »