Carbon Fiber Molds Transforming Production with Lightweight Efficiency

In the rapidly evolving world of manufacturing, the quest for materials that offer superior performance without compromising on weight has led to the rise of carbon fiber. This miraculous material, known for its exceptional strength-to-weight ratio, has found its way into various applications, from aerospace to automotive industries. One such application that is gaining significant traction is the use of carbon fiber in mold making. In this blog, we will explore the benefits, applications, and future prospects of carbon fiber molds compression molding.

Table of Contents

Toggle

Benefits of Carbon Fiber Molds

Lightweight and High Strength

The most apparent advantage of carbon fiber molds is their lightweight nature. This reduces the load on the machinery and allows for faster cycle times, leading to increased production rates. The high strength of carbon fiber ensures that these molds can withstand the rigors of repetitive manufacturing processes without deforming.

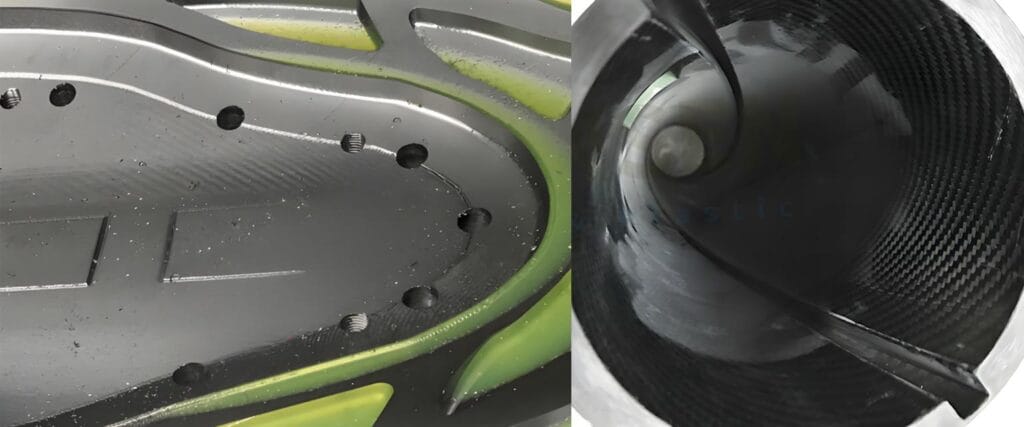

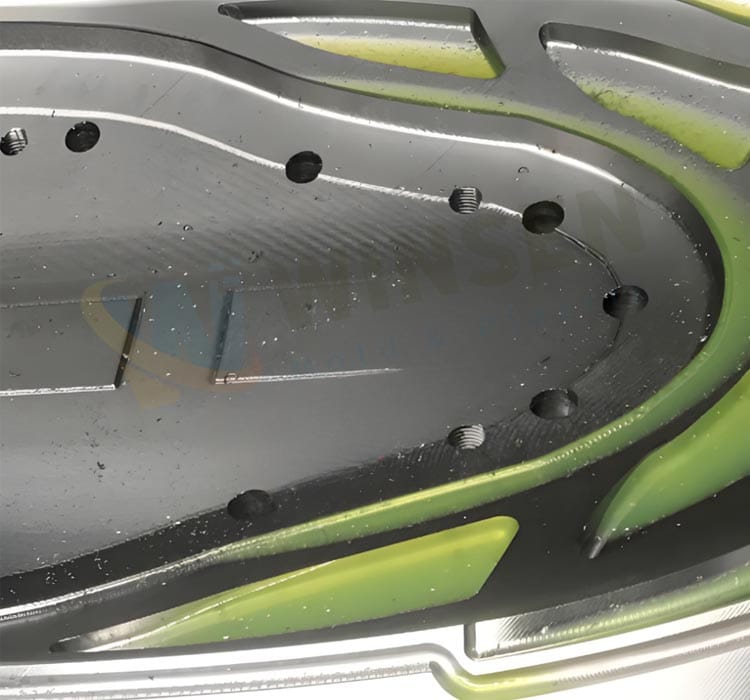

The obvious advantages of carbon fiber composite molds include light weight and high rigidity. Furthermore, the mold surface of carbon fiber composite molds is formed by prepreg layup, allowing for easy repair and reuse, resulting in high efficiency.

Thermal Stability

Carbon fiber has a low coefficient of thermal expansion, which means it does not expand or contract significantly with temperature changes. This property is crucial in molding processes where precise temperature control is necessary to achieve the desired part properties. It ensures that the mold maintains its shape and dimensions, leading to consistent part quality.

A thermal expansion coefficient close to that of the molded carbon fiber composite component, and high dimensional accuracy.

Cost-Effectiveness

While the initial investment in carbon fiber molds can be higher than traditional molds, the long-term cost savings are substantial. The durability and longevity of carbon fiber molds mean they require less maintenance and have a longer service life. Additionally, the reduced energy consumption during manufacturing processes can lead to significant cost savings over time.

Environmentally Friendly

Carbon fiber molds contribute to more sustainable manufacturing practices. Their lightweight nature reduces the carbon footprint associated with transportation. Moreover, the longer life span of these molds means fewer replacements are needed, reducing waste.

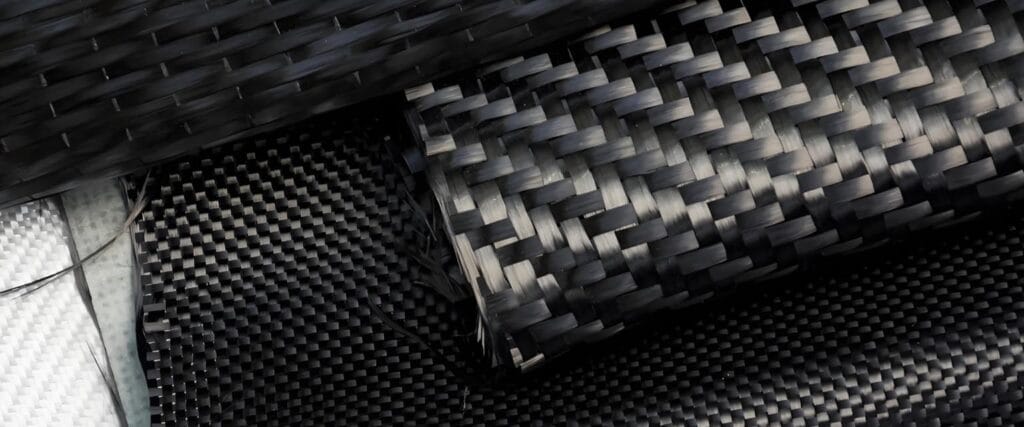

What we often refer to as “carbon fiber” is actually carbon fiber composite material, and carbon fiber composite material isn’t the only material used in the mold. This is because carbon fiber’s exceptional stiffness is conditional: when used alone, it’s very brittle and prone to splitting and cracking. To preserve its properties, the carbon fiber is impregnated with epoxy resin (a glue-like material) before being placed in the mold, creating a composite material.

The carbon fiber composite mold we’re referring to is actually a fiber-reinforced, resin-based composite structure. Its manufacturing process is similar to that of carbon fiber composite molding: the carbon fiber composite material is applied to a transitional core mold using ply layup or other methods, and then cured to form the mold. Of course, before use as a mold, it undergoes some post-processing, such as trimming, sanding, surface adhesive coating, and assembly.

Unlike metal, carbon fiber’s stiffness is easier to control; its stiffness characteristics are only exhibited in a single direction, so its stiffness can be adjusted based on how the carbon fiber composite is aligned or how it is positioned within the mold. This is known as anisotropy. Metals, in contrast, are isotropic, exhibiting the same strength and stiffness properties in all axial directions.

What to consider when designing carbon fiber composite molds

Key considerations when designing molds include operating temperature, thermal expansion properties, strength and stiffness, and mold manufacturing process performance. Large molds, in particular, must possess sufficient stiffness and strength to meet all molding process requirements and maintain shape and dimensional stability under high temperatures and pressures.

Applications of Carbon Fiber Molds

Aerospace Industry

In the aerospace sector, where weight reduction is critical for fuel efficiency and performance, carbon fiber molds are used to produce lightweight and strong components. From aircraft fuselages to satellite components, these molds help in creating parts that meet stringent aerospace standards.

Automotive Industry

The automotive industry is another significant user of carbon fiber molds. They are used to manufacture high-performance parts such as body panels, chassis components, and interior fittings. The use of carbon fiber in these applications not only reduces vehicle weight but also improves safety and handling.

Consumer Electronics

In the consumer electronics sector, carbon fiber molds are used for producing lightweight and durable casings for smartphones, laptops, and other devices. The precision of these molds ensures that the components fit perfectly, enhancing the overall quality of the products.

Sporting Goods

Carbon fiber molds are also used in the production of high-performance sporting goods such as bicycles, golf clubs, and tennis rackets. The lightweight and high-strength properties of carbon fiber make these products more durable and responsive.

Challenges and Future Prospects

Despite the numerous benefits, there are challenges associated with the use of carbon fiber molds. The high initial cost and the need for specialized knowledge and equipment can be prohibitive for some manufacturers. However, as technology advances and the demand for lightweight and high-performance materials grows, the adoption of carbon fiber molds is expected to increase.

Future developments in carbon fiber technology are likely to focus on making these molds more affordable and easier to produce. Innovations in 3D printing and automation could play a significant role in reducing production costs and simplifying the manufacturing process.

Conclusion

Carbon fiber molds represent a significant advancement in the field of manufacturing tooling. Their lightweight, high-strength, and thermal stability properties make them ideal for a wide range of applications. As the manufacturing industry continues to evolve, the adoption of carbon fiber molds is poised to grow, driving innovation and enhancing the performance of products across various sectors. The future looks promising for carbon fiber molds, and their impact on manufacturing will likely be as transformative as the material itself.