The Different of Composite Molding and Manufacturing

Composite materials have revolutionized the manufacturing industry, offering a versatile and durable alternative to traditional materials. By combining multiple substances, often polymers and fibers, these composites provide enhanced strength, reduced weight, and improved performance characteristics. In this article, we delve into the various types of composite compression molding and manufacturing processes, shedding light on their unique applications and benefits.

Table of Contents

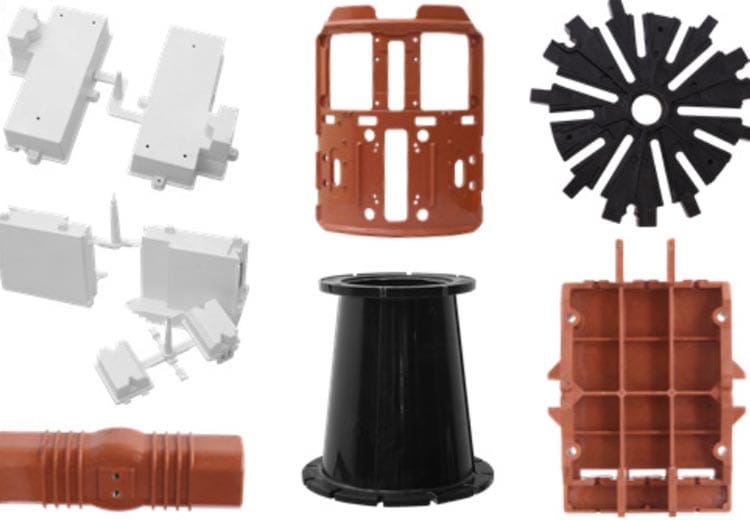

ToggleComposite Molding Mould

Composite Molding Parts

The Essence of Composite Molding

Composite molding is the process of shaping composite materials into specific forms for manufacturing purposes. This involves combining different materials to create a single, superior product. The versatility of composite materials makes them ideal for a wide range of applications, from automotive parts to aerospace components and beyond.

Types of Composite Manufacturing Processes

There are several primary methods used in composite manufacturing, each tailored to specific requirements and applications. Let’s explore these methods in detail:

1. Open Molding

Open molding is a straightforward and cost-effective method where composite materials are poured into a mold that is open to the atmosphere. The material then hardens and cures through exposure to air. This method is particularly useful for short production runs or when testing prototype designs. Its simplicity and affordability make it a popular choice for small-scale projects.

2. Closed Molding

Closed molding, as the name suggests, involves creating the composite within a sealed mold. Typically, the mold consists of two parts that press together to form the desired shape. This method is often referred to as vacuum molding due to the use of vacuum pressure to ensure a precise fit and uniform distribution of materials. Closed molding is ideal for high-volume production runs and when both sides of the finished product require a smooth, finished surface.

3. Cast Polymer Molding

Cast polymer molding is a versatile process that can incorporate either open or closed molding techniques. The composite material is poured into the mold and left to solidify and harden. This method is widely used for creating parts with intricate designs and complex geometries, making it a popular choice in industries such as automotive and consumer electronics.

Methods of Composite Material Fabrication

The creation of composite materials involves combining various substances to achieve the desired properties. Here are some common methods used in composite fabrication:

1. Filament Winding

Filament winding involves winding fiber tape or filament tape into a resin to add strength. The filament is passed through a resin bath and then wound continuously onto a mandrel. This method is particularly effective for creating hollow, cylindrical parts such as pipes and tanks, offering high strength-to-weight ratios.

2. Hand Layup

Hand layup is a manual process where pre-impregnated woven fabrics or mats are chopped into pieces and woven into the resin. This method is labor-intensive but allows for customization and flexibility in the design of the composite material. It is commonly used for small-scale production and custom projects.

3. Tape Laying

Tape laying is similar to hand layup but involves using strips of fabric that are layered with resin to create the composite. This method is ideal for creating large, flat panels and can be automated for increased efficiency and precision.

4. Injection Molding

Injection molding involves heating materials such as plastic or resin and injecting them into a mold to create the desired shape. This method is highly efficient for mass production and allows for the creation of complex shapes with high precision.

5. Compression Molding

Compression molding involves pressing sheets of material, such as fiberglass mats, between two mold halves to create the composite. This method is suitable for creating parts with high strength and durability, making it a popular choice in the automotive and aerospace industries.

6. Pultrusion

Pultrusion is a continuous process where fibers are pulled through a resin bath and then through a heated die to create a composite profile. This method is ideal for creating long, continuous parts with uniform cross-sections, such as rods and beams.

The Importance of Composite Molding in Modern Manufacturing

Composite molding has become an integral part of modern manufacturing, offering numerous advantages over traditional materials. From automotive manufacturers seeking lightweight yet strong components to aerospace engineers demanding high-performance materials, the applications of composite molding are vast and varied. Whether you are looking to create a prototype or produce thousands of parts, composite molding offers a reliable and efficient solution.

If you are considering incorporating composite materials into your manufacturing process, it’s essential to choose a reputable and experienced partner. At [Your Company Name], we specialize in providing high-quality composite solutions tailored to your specific needs. Contact us today to discuss your project and discover how composite molding can transform your manufacturing capabilities.