In-depth review of compression molds and Punch Die Tooling

The evolution of compression tooling technology is revolutionizing numerous high-precision manufacturing industries—from composite molding and automotive parts manufacturing to pharmaceutical tablet compression. WS Mould is at the forefront of this technological revolution, providing high-strength, high-consistency, and high-durability punch and die systems and tablet compression tooling solutions.

Table of Contents

ToggleIn modern manufacturing, tooling accuracy directly determines product performance. Every micron of precision deviation can impact the efficiency of material forming, compacting, and demolding. This article will systematically introduce the structure, operating principles, materials science, and applications of compression tooling, and explore how WS Mold is leading the industry through advanced processing and testing technologies.

Innovations in compression mold technology are reshaping the high-precision manufacturing industry. WS MOLD with its micron-level precision and cutting-edge material science, provides durable and reliable stamping and mold systems for the pharmaceutical, automotive, and composite materials industries, leading the new trend of intelligent manufacturing and sustainable development.

What are Compression Tooling, Punch & Die Tooling systems

Compression tooling is a system consisting of a matched punch and die cavity that compresses materials into a predetermined shape using controlled pressure and temperature. This process relies on high-precision metal dies to ensure uniform density, smooth surface finish, and accurate dimensions.

In a punch and die tooling system, the punch is a male die inserted into a female die cavity, applying pressure to compress powder, resin, or composite sheet into a specific geometry. This type of tooling system is widely used in the following areas:

- Tablet production in the pharmaceutical industry

- Compression molding of SMC/BMC composites

- Powder metallurgy and ceramic molding

- Electrical and thermoset component manufacturing

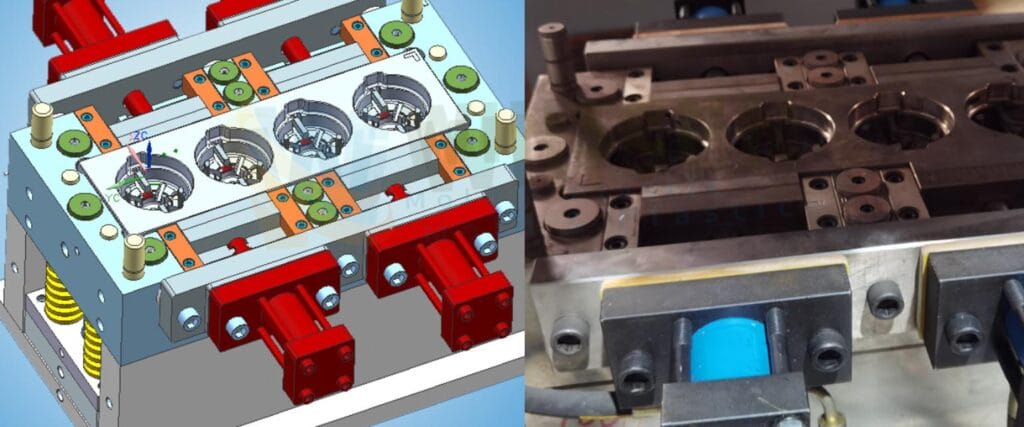

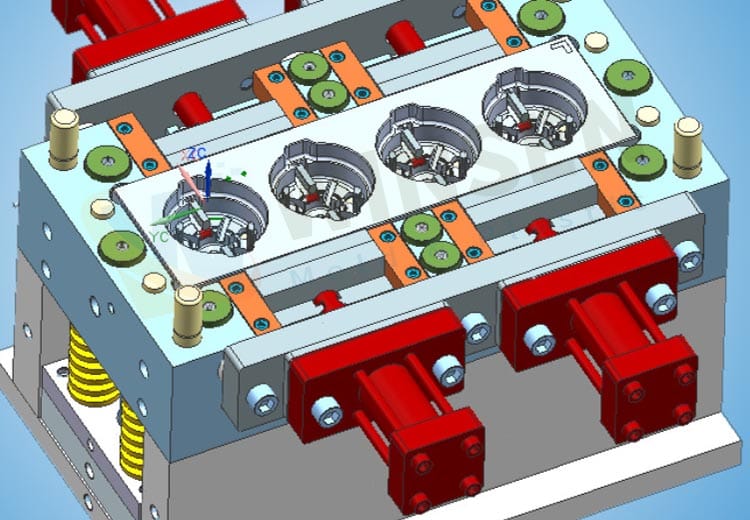

Mold Design and Construction

A high-quality compression mold consists of several key components: the punch, cavity, guide assembly, and some preform supports and ejection systems. Each component must exhibit precise coaxiality, thermal stability, and mechanical durability.

- Upper and lower punches: These are critical components for applying mold pressure. Shuangsheng Plastics utilizes mirror-polished punches to reduce sticking and wear.

- Mold cavities: Hardened and ground to ensure micron-level dimensional stability even after repeated use.

- Mold base/base plate: Ensure mold alignment and evenly distribute compression loads.

- Cooling channels: These are used for temperature control during thermoset or composite molding.

Materials and Surface Treatment

The choice of mold material is crucial for hardness, wear resistance, and dimensional accuracy. Shuangsheng Mould utilizes a variety of high-performance steels and surface coating technologies to achieve superior performance:

- Mold Steel: H13, D2, and DC53 steels are selected for their high toughness and high-temperature resistance.

- Stainless Steel: Used in pharmaceutical molds for corrosion and contamination resistance.

- Surface Treatment: Nitriding, TiN coating, CrN coating, and hard chrome plating enhance wear resistance and extend service life.

- Polishing and Passivation: Ensure a smooth surface to prevent sticking during tableting or resin curing.

Compression and Tablet Tooling Die Applications

Compression die tooling versatility lies in its ability to meet the molding needs of diverse materials and industries:

- Pharmaceuticals: Tablet compression dies ensure consistent tablet dosage, clear markings, and meet FDA surface requirements.

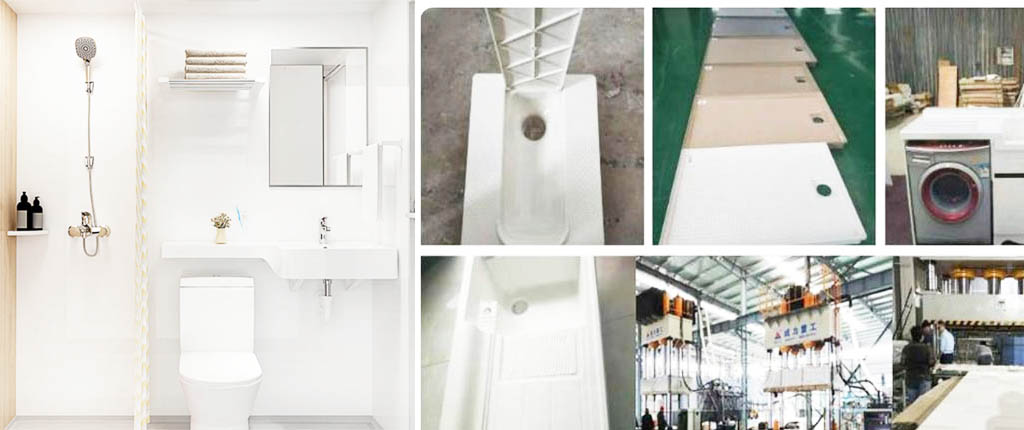

- Composites and Automotive: SMC and BMC compression dies are used for engine covers, electric vehicle battery housings, and structural panels.

- Electrical Components: Thermoset compression dies are used to produce switches, insulators, and housings, providing excellent electrical insulation properties.

- Powder Metallurgy: Punch and die sets are used to press powdered metal gears, bushings, and sintered structural parts.

WS Mould's Engineering and Manufacturing Process

WS Mold utilizes an integrated manufacturing system that combines advanced CAD/CAM modeling, CNC machining, EDM (Electrode Design Molding), and three-dimensional coordinate measuring (CMM) inspection technologies.

- 3D modeling and simulation: Finite element analysis predicts stress and deformation, ensuring accurate and reliable mold design.

- Multi-axis CNC machining: Achieve high-precision machining and mirror-polished surfaces.

- Heat treatment: Optimizes hardness and dimensional stability.

- Quality control: Strictly adheres to ISO 9001 standards, ensuring every part passes hardness and dimensional inspection.

This high-precision engineering system ensures that every compression moulding system meets international quality standards.

Innovations in Compression Molds

WS Mould continues to innovate in compression mold technology, introducing intelligent manufacturing and sustainable solutions:

- Digital twin simulation: Predicts molding cycle time, curing uniformity, and mold wear distribution.

- Smart sensing technology: Enables real-time monitoring of mold temperature and pressure.

- Recyclable composite molds: Support green manufacturing and material recycling.

- 3D-printed inserts: Shorten prototyping cycles and improve mold efficiency.

Conclusion

From tablet compression molds tooling that ensure pharmaceutical precision to punch and die systems that shape the future of composite materials, Shuangsheng Mould is a trusted tooling partner for customers worldwide. Leveraging materials science, automation, and decades of manufacturing experience, Shuangsheng provides customers with durable, high-precision, and cost-effective compression mold solutions.

Contact WS MOLD to learn about our full line of compression molds, punches, and die systems, as well as tablet compression mold solutions.