Compression vs. Injection Molding,in the world of mass production of plastic products, mold selection is a crucial step that determines success or failure. Compression molding and injection molding, as two mainstream processes, often leave purchasing managers, R&D engineers, and even business owners struggling with the question: which one is more suitable for my project? Should I pursue the lower cost of compression molding or the higher precision of injection molding? In 2026, with fluctuating raw material prices, compressed delivery times, and upgraded quality requirements, this choice has become even more complex.

Table of Contents

ToggleThis article will use a comparison table, three real-world case studies, and a practical selection checklist to break down the differences between compression molding and injection molding in terms of cost structure, delivery cycle, and quality ceiling, so you can avoid pitfalls in your next mold investment.

Process Principles: Understand their Difference in 5 Seconds

| Aspect | Compression Molding | Injection Molding |

|---|---|---|

| Charge loading | Weighed “biscuit” or sheet placed in open cavity | Pellets fed via hopper into heated barrel |

| Clamping force | 15–30 MPa, shape cured under vertical pressure | 30–120 MPa, melt injected at high pressure |

| Cure / cool | Thermoset cross-links (exothermic) | Thermoplastic freezes in tool |

| Typical polymers | SMC, BMC, phenolic, epoxy | ABS, PC, PP, PA, PBT |

| Max. part footprint | 2 m × 4 m (e.g. automotive tail-gate) | Usually < 1 m (machine tonnage limit) |

Rule of thumb:

Compression = “hot-press sintering,” ideal for thermosets, large panels and thick walls.

Injection = “high-pressure casting,” ideal for thermoplastics, intricate ribs and tight tolerances.

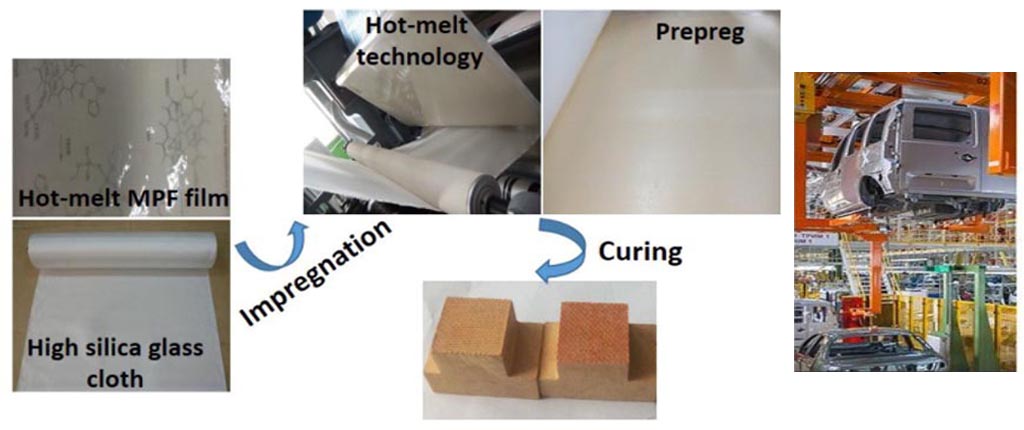

When it comes to construction, FRP panel molds offer significant benefits. FRP stands for “fiberglass reinforced plastic,” which means these molds are not only durable but also designed for longevity. They can be reused multiple times without compromising quality. WS’s FRP panels Molds are engineered to endure the tough conditions often found on construction sites. This makes them an ideal choice for builders looking for reliable and cost-effective solutions.

Cost breakdown: Where does the money go when producing 100,000 units per year?

Suppose we want to produce an appliance housing that is 400 mm × 300 mm × 3 mm in size, with an annual demand of 100,000 units. We will conduct economic calculations using BMC molding and ABS injection molding respectively (average purchase price in East China in Q1 2025).

| Line item | BMC-compression | ABS-injection | Notes |

|---|---|---|---|

| Tool steel | P20 adequate, USD 5 800 | H13 thru-hardened, USD 9 400 | Lower pressure = longer tool life |

| Press / machine | 400 t press USD 21 / h | 380 t injector USD 25 / h | Slower cycle offsets lower rate |

| Material | BMC 1.30 USD / kg | ABS 1.89 USD / kg | Part mass 0.65 kg vs 0.38 kg due to SG |

| Cycle | 120 s | 45 s | Curing + vent time in BMC |

| Labor / handling | 0.8 min manual charge | 0.1 min auto feed | Compression more operator-heavy |

| Total piece cost | USD 1.68 | USD 1.61 | Difference < 5 c; compression tool lasts 500 k shots vs 300 k |

Take-away: At ≥ 2.5 mm wall and mid-volume, the two technologies cost-parity. Once annual demand climbs past 300 k, injection’s cycle advantage pulls piece cost down another 8–12 %—unless compression moves to multi-cavity or servo-press speed-packs.

Lead-time reality: from CAD to T0 sampling

| Milestone | Compression | Injection |

|---|---|---|

| Mold design | 5 d | 5 d |

| Rough-machining | 7 d | 10 d (heat-treat added) |

| Fitting & assembly | 3 d | 3 d |

| First trial (T0) | Day 15 | Day 18 |

| Iteration cycle | + 3 d / round | + 3 d / round |

Key differences: Compression molding eliminates the need for hot runners, saving 5-7 days; if the product has a textured finish, BMC can directly include the texture sheet, saving on texture electrode processing; injection molding requires re-quenching if the structure is changed, adding another 2 days.

Therefore, when rushing to produce exhibition samples/first versions, compression molding can often deliver a week earlier than injection molding. This is a hidden advantage for Tier 1 suppliers who need to quickly deliver samples to OEMs.

Quality ceiling – comparing precision, surface & strength

| Metric | BMC-compression | ABS-injection | Winner |

|---|---|---|---|

| Dimensional tol. | ±0.15 mm | ±0.05 mm | Injection |

| Parting-line flash | 0.05–0.1 mm | 0.02 mm | Injection |

| Fiber orientation | Random (isotropic) | Flow-directed (warpage) | Compression |

| Surface gloss | Matte, built-in texture | Mirror gloss Ra 0.025 µm | Injection |

| Heat distortion temp. | HDT > 200 °C | HDT 95 °C | Compression |

| UL-94 @ 1.5 mm | V-0 natively | V-0 needs additives | Compression |

- Visible cosmetics, snap-fits, gears → injection.

- Heat-proof, electrical insulation, large flat panels → compression.

. 2026 quick-selection scorecard

- Wall thickness < 2 mm (Yes = 5)

- Annual volume > 300 k (Yes = 5)

- Needs metallisable / high-gloss surface (Yes = 5)

- Continuous use > 120 °C (Yes = 1)

- Longest panel dimension > 1 m (Yes = 1)

- Contains ribs / snaps < 0.3 mm (Yes = 5)

Case flash-back: How we saved a client USD 380 k

- Material: UV-stable BMC, 10 % glass

- Tool: 2-cavity P20, vacuum hardened

- Cycle: 95 s @ 165 °C on 600 t servo press

- Result: Flatness 0.05 mm, HDT 180 °C, passed IEC 60598-1

- Economics: Mold premium USD +8 k, but eliminated post-bake & aluminium stiffener → USD 380 k / yr savings.

2026 trend alerts – hybrid routes gaining traction

- “Compression + Injection” two-shot: BMC carrier first, TPE seal second—one cell, zero assembly, already running on Chinese battery housings.

- In-mold UV coating for compression: matte-black Ra ≤ 0.2, piano-black alternative without painting line.

- End-of-life regulations: solvolysis now cracks thermosets back to filler 40 %; carbon footprint drops 18 %—EU customers already paying a premium for recycled content.

Bottom line & action plan

- Thick walls, temp > 120 °C, large flat surfaces, moderate volumes → compression molding usually matches or beats injection on total cost.

- Complex geometry, thin walls, snap-fits, high gloss, giant volumes → injection offers speed & precision.

- Borderline projects → run the scorecard above, prototype both routes with 3-D printed cavities, and freeze the steel in 15 days, not 15 weeks.

A 2026 Guide to Cost, Lead-Time & Quality Differences in Compression Molding and Injection Molding.

Selecting the right molding process is often the single biggest make-or-break decision in plastics manufacturing. Compression (compression-molding) tools and injection molds both dominate high-volume production, but they speak totally different “languages” when it comes to dollars, days and dimensional accuracy. With raw-material prices volatile, lead-times shrinking and quality bars rising in 2026, the choice has never been more complex.

Above you’ll find a side-by-side matrix, three real-world case studies and a ready-to-use selection checklist that will keep your next tool investment off the critical-path “hot list.”