Introduction to Compression Molding

How to Improve the Quality of Composite Material Compression Moulding Mould? Pre-shipment electroplating chrome treatment is a good solution to improve the quality of composite molding mould.

Table of Contents

ToggleIn modern composite manufacturing, composite compression molding tools play a key role in producing lightweight, durable and high-performance parts. These tools are widely used in industries such as automotive, electrical, aerospace and bathroom, and are particularly suitable for processing thermoset materials such as SMC (sheet molding compound), BMC (bulk molding compound) and carbon fiber prepreg.

One of the most important improvements to this type of mold is the electroplating chrome surface treatment before shipment. This chrome layer not only protects the mold surface, but also improves part quality and extends the life of the mold. This article will focus on the structure, advantages and chrome electroplating treatment of composite molding molds before shipment.

Understanding Composite Compression Molding Mould

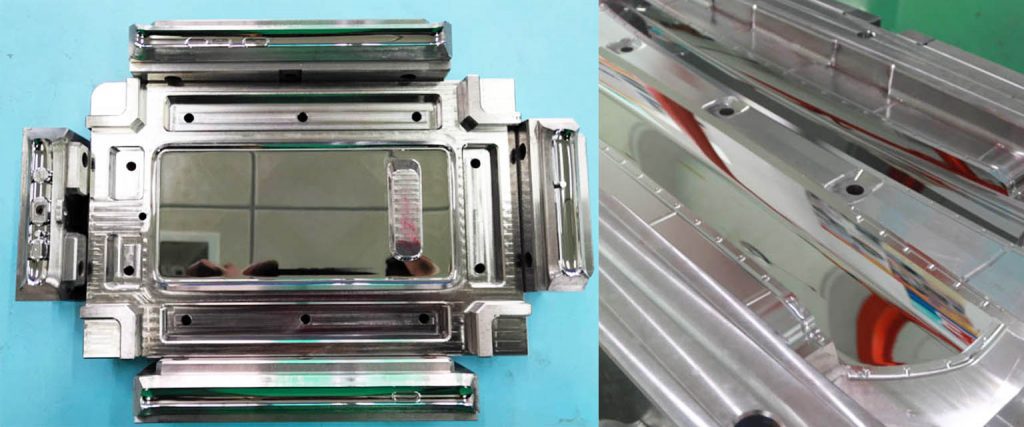

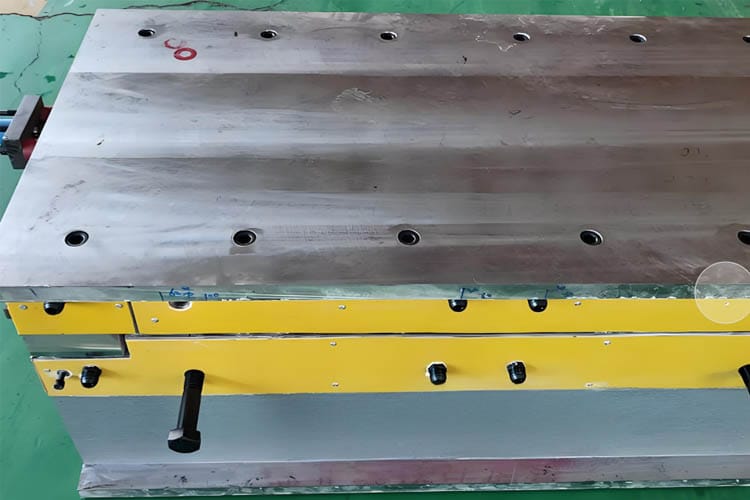

Compression molding moulds for composite materials are precision tools used to mold composite materials under high temperature and pressure, usually in conjunction with hydraulic or mechanical presses. These dies are generally designed in two parts – a punch and a die – to encapsulate the molding material during the pressing process.

Compression molding continues to thrive in industries that demand high-strength, fiber-reinforced or thermoset parts—automotive under-hood components, aerospace radomes, electrical insulators, consumer appliance housings and, increasingly, battery enclosures for EVs.

Understanding the Importance of Mold Quality in Compression Molding

Compression molding involves placing a pre-measured amount of material into a heated mold cavity and applying pressure to shape the material into the desired form. The mold is the heart of this process, and its quality directly impacts the part’s dimensional accuracy, surface finish, and overall consistency. Poor mold quality can lead to issues like flash, voids, warpage, and inconsistent part dimensions, which can increase scrap rates, reduce productivity, and compromise part performance.

Commonly processed composite materials

- SMC (sheet molding compound)

- BMC (bulk molding compound)

- Carbon fiber reinforced plastic (CFRP)

- Glass fiber thermoplastic (GMT)

- Thermosetting laminates

Key Applications of composite products

- Automotive body panels and doors

- Truck and electric vehicle battery pack housings

- Electrical enclosures and distribution boxes

- Shower trays, bathtubs and washbasins

- Carbon fiber structural parts

Design and Engineering Points

Compression molds for composite materials need to have a strong structure and precise dimensions to withstand repeated compression molding cycles. Key design factors include:

- Thermal control: integrated heating and cooling systems to ensure optimal resin curing

- Fiber orientation: mold geometry must facilitate fiber flow and pressure distribution

- Demolding structure: properly designed demolding slopes, ejector systems and surface coatings facilitate smooth demolding

- Durability: use P20, H13 or high hardness mold steel to enhance wear resistance and deformation resistance

Optimize mold design

- Wall thickness uniformity: Maintain uniform wall thickness in the mold to prevent uneven cooling and warping. Thickness variation can cause shrinkage or stress in the molded part.

Demolding angle: Design a reasonable die-out angle (usually 1-3° is recommended) to facilitate easier demolding and reduce the risk of product damage. - Rib design: When adding structural support ribs, ensure that their thickness and spacing are appropriate to avoid weak points and stress concentration in the molded part.

Exhaust and ejection system

- Exhaust channel: Set small exhaust channels at key points to exhaust trapped air during the molding process to improve surface finish.

- Ejector design: Reasonably arrange the ejector position to ensure that the ejector is evenly arranged to avoid part deformation

Heating and cooling channels

- Uniform heating: Ensure that the mold is heated evenly to avoid hot or cold spots, thereby preventing deformation or uneven curing of the finished product.

- Cooling channel layout: Implement a balanced cooling system to manage heat loss, shorten cooling time and prevent warping. Use simulation tools to optimize cooling channel design to ensure cooling efficiency and uniformity

What is pre-shipment electroplating chrome surface treatment?

Electroplating chrome treatment, also known as hard chrome plating, is the process of applying a thin layer of chrome to the mold surface. For composite molds, this treatment is usually performed after the final polishing is completed and before shipment. It can form a high-hardness, corrosion-resistant surface, allowing the mold to perform better in high-temperature and high-pressure molding environments.

Key advantages of electroplated chrome molds

- Wear resistance: can extend the service life of molds in high-wear composite molding;

- Corrosion resistance: prevent rust and chemical corrosion of resin systems;

- High-quality surface effect: the surface of molded parts is smoother, reducing subsequent processing steps;

- Mold release performance: reduce mold sticking, improve mold release efficiency, and reduce the use of mold release agents;

- Dimensional stability: the mold can still maintain accuracy after multiple uses.

Why choose chrome plating before shipment?

At WS Mould, each mould will undergo a detailed surface treatment process before shipment. Chrome plating before shipment is our commitment to quality, ensuring that customers receive moulds that can be put into use immediately and have long-term value.

Our chrome plating process includes

- Surface pre-treatment: polishing and degreasing cleaning;

- Nickel underlayer (optional): enhances adhesion and durability;

- Hard chrome plating: plating thickness ranges from 0.02mm to 0.1mm depending on mold type;

- Final inspection and measurement: confirm surface hardness, glossiness and thickness uniformity.

Quality Control and Export Standards

Our chrome plating molds are tested in simulated working conditions to ensure resistance to thermal fatigue and chemical corrosion. WS follows international quality standards such as ISO 9001 and all molds are shipped with:

3D and 2D mold drawings

Material qualification certificate

Chrome layer thickness test report

Mold trial video and pictures

Which industries benefit from chrome electroplating composite molds

- Automotive industry: electric vehicle battery covers, interior parts, trunk covers, etc.

- Bathroom industry: bathroom bases, SMC bathtubs, etc.

- Energy industry: composite electrical housings, wind blade components

- Aerospace: carbon fiber panel molding molds

Conclusion

Compression molding dies with pre-shipping chrome plating are ideal for manufacturers seeking high surface quality, longer service life and low maintenance requirements. At WS Mold, we combine advanced mold design with precise surface treatment technology to provide one-stop mold solutions that exceed industry standards.

If you are looking for a trusted long-term partner in compression molding, WS Mold will provide full support for your project from design to delivery.