Carbon fiber material products' requirements for mold processing

Unlock the pivotal role of mould processing in crafting carbon fiber material products. Carbon fiber, known for its exceptional strength-to-weight ratio, has become a cornerstone in the production of high-performance components across various industries. From automotive to aerospace and sporting goods, the demand for carbon fiber components is soaring. However, the manufacturing of these components is contingent upon the quality and precision of the molds used. This blog delves into the specific requirements that carbon fiber material products impose on mold processing, exploring the nuances of mold design, material selection, and processing techniques that are pivotal for success in this domain.

Table of Contents

Toggle

What are the requirements for processing of carbon fiber product molds

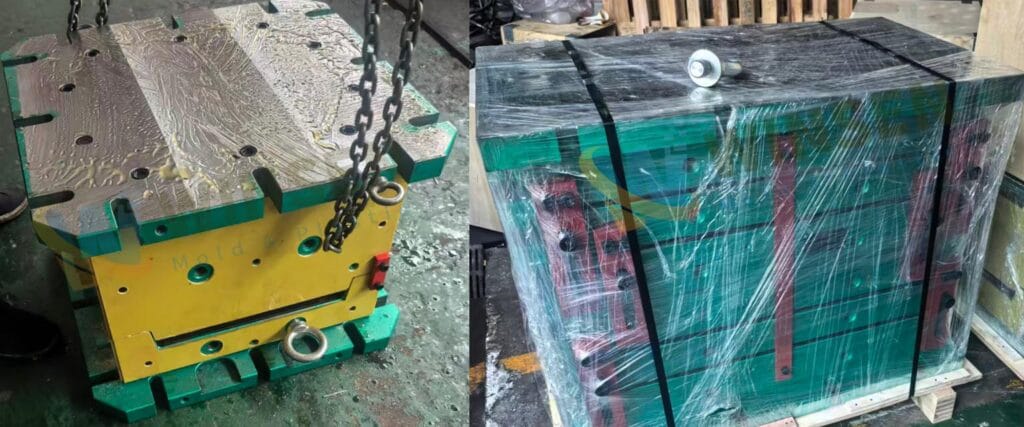

The resin transfer molding process utilizes low-pressure molding. For low-pressure injection molding, fiberglass molds, aluminum molds, epoxy molds, or wood molds can be used. However, molds made of these materials are susceptible to significant precision errors during the high-temperature curing process. Stainless steel molds are the best choice for ensuring design accuracy.

Under normal circumstances, the following requirements are placed on carbon fiber molds for product production:

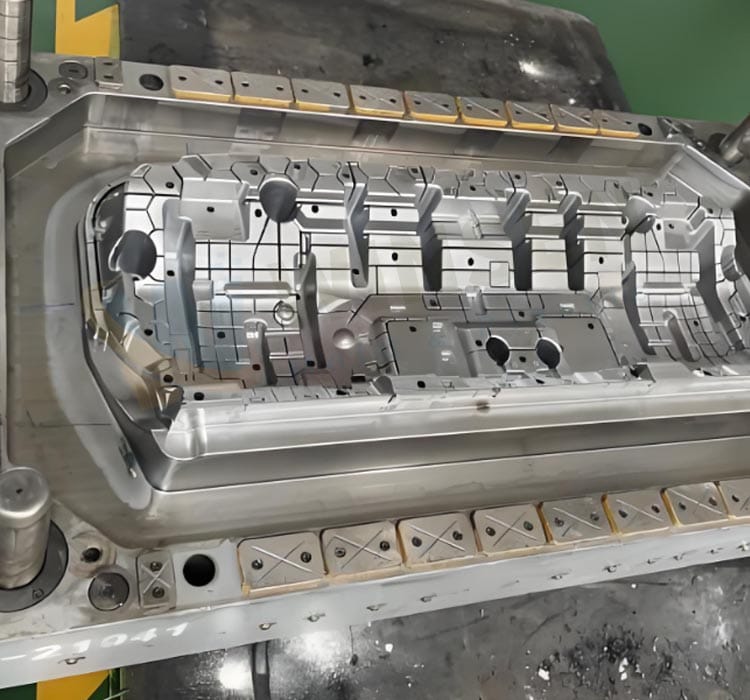

- 1. Because resin injection is required, the mold must have both injection and exhaust ports, ensuring a complete seal. Air leakage must be avoided during the resin injection process, especially during vacuum liposuction. The mold’s sealing directly impacts the quality of the carbon fiber product.

- 2. The mold must be designed with upper and lower mold guides and positioning devices, a mold locking mechanism, and a mold release mechanism.

- 3. The mold cavity dimensions must be accurate, the upper and lower molds must fit together accurately, and the mold surface must have high surface precision.

- 4. It must possess sufficient strength and rigidity to withstand the injection pressure.

- 5. It must have a heating device capable of heating the mold to a certain temperature (60-120°C), ensuring uniform temperature distribution across the mold surface and enabling temperature monitoring and adjustment.

Design Considerations for Carbon Fiber Molds

- The design of a carbon fiber mold is a critical aspect that dictates the quality and functionality of the final product. Key considerations include:

Dimensional Stability: Given the high precision required for carbon fiber components, molds must maintain their shape and size under varying temperatures and pressures without distortion. - Surface Finish: The mold’s surface quality directly influences the aesthetic and structural integrity of the carbon fiber product. High-quality surface treatment is essential to achieve a smooth, defect-free finish.

- Injection and Venting: Molds must incorporate injection points for resin and adequate venting to prevent air entrapment, which can compromise the quality of the final product。

- Ejection Mechanism: Considering the strength and stiffness of carbon fiber, molds need a robust ejection system to release the product without damage

Material Selection for Molds

Selecting the right material for carbon fiber molds is crucial. Ideal materials should possess:

- High Strength and Durability: To withstand the repeated heating and cooling cycles inherent in the manufacturing process.

- Thermal Stability: To maintain dimensional accuracy during the curing process of carbon fiber components.

- Chemical Resistance: To resist the corrosive nature of resins and other chemicals used in carbon fiber production.

- Ease of Machining: To facilitate the creation of complex mold designs that are often required for carbon fiber components.

Processing Techniques for Carbon Fiber Molds

The processing of carbon fiber molds involves several sophisticated techniques:

- CNC Machining: Utilizing computer numerical control (CNC) machines for precision cutting and shaping of the mold components ensures accuracy and repeatability.

- Surface Treatment: Techniques such as polishing, coating, and plating enhance the mold’s surface quality and durability.

- Heat Treatment: Applying specific heat treatments can improve the mold’s mechanical properties and resistance to thermal shock.

- Quality Control: Rigorous inspection and testing at various stages of mold production ensure that the final product meets the stringent standards required for carbon fiber components.

Challenges in Mold Processing for Carbon Fiber

Despite the advantages, there are challenges associated with processing molds for carbon fiber products:

- Complex Geometry: The intricate designs often required for carbon fiber components can make mold manufacturing more difficult and time-consuming.

- High Precision Requirements: The need for extreme precision in mold dimensions can demand advanced equipment and skilled operators.

- Material Costs: The specialized materials suitable for carbon fiber molds can be costly, impacting the overall production budget.

Future Prospects of carbon fiber mould

As technology advances, the future of mould processing for carbon fiber looks promising. Innovations in additive manufacturing (3D printing), automation, and material science are expected to make mold production more efficient and cost-effective。 Additionally, the development of new materials and coatings could further enhance the performance and lifespan of carbon fiber molds.

Conclusion

The manufacturing of carbon fiber material products relies heavily on the precision and quality of the molds used. From design considerations to material selection and processing techniques, each aspect plays a critical role in determining the success of carbon fiber components. As the demand for carbon fiber products continues to grow, so too will the importance of advancements in mold processing technologies. Manufacturers who invest in state-of-the-art mold production capabilities will be well-positioned to meet the challenges and opportunities presented by the carbon fiber market.