Multi-Cavity Molds: The Engine Driving High-Volume Plastic Part Manufacturing

In the fast-paced world of plastic injection molding, efficiency is king. Meeting demanding production targets while controlling costs is a constant challenge. This is where the multi-cavity mold emerges not just as a tool, but as a strategic powerhouse. It’s the cornerstone technology enabling the mass production of identical plastic components that fill our everyday lives, from bottle caps and electrical connectors to intricate medical device parts.

Table of Contents

Toggle

Beyond the Single: Understanding the Multi-Cavity Core Concept

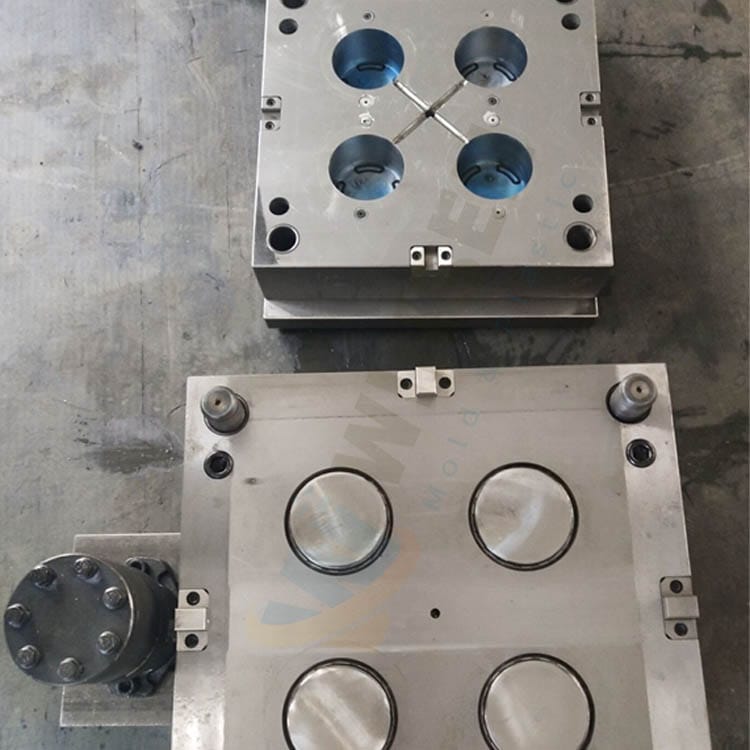

At its most fundamental level, a mold consists of two halves (core and cavity) that form the negative space of the desired part. Molten plastic is injected under high pressure into this space, cools, and solidifies. The mold then opens, the part is ejected, and the cycle repeats.

A single-cavity mold produces one part per injection cycle. Simple, effective, but inherently limited in output. A multi-cavity mold fundamentally changes the game. It incorporates multiple identical cavities within the same mold base. During a single injection cycle, plastic flows through a network of runners and gates, filling all cavities simultaneously. The result? Multiple identical parts are produced every time the mold opens and closes.

The Driving Force: Why Choose Multi-Cavity Mold?

Dramatically Increased Production Rates (The Cavity Multiplier Effect):

This is the most significant benefit. If a single-cavity mold produces 100 parts per hour, a well-designed 8-cavity mold can theoretically produce 800 parts per hour using the same machine cycle time. This multiplier effect is transformative for meeting large orders and reducing overall manufacturing lead times.

Lower Cost Per Part

While the initial cost of designing and manufacturing a multi-cavity mold is higher than a single-cavity version, this cost is amortized over the vastly larger number of parts produced. The cost contribution of the mold per individual piece plummets. Additionally, the machine time (a major cost factor) is used far more efficiently per part produced.

Enhanced Consistency

When cavities are machined to identical specifications within the same mold base and fed by a balanced runner system, the parts produced across cavities exhibit extremely high dimensional consistency and repeatability. This reduces part-to-part variation, crucial for assembly and quality control.

Optimized Machine Utilization

Injection molding machines represent a significant capital investment. Multi-cavity molds maximize the output from each machine cycle, ensuring these expensive assets are utilized at peak efficiency, improving the return on investment (ROI) for the entire production line.

Reduced Labor Costs (Per Part)

While operators are still needed, the labor cost associated with handling and secondary operations is spread across many more parts per cycle.

The Intricate Dance: Design Considerations & Challenges

Designing and building an effective multi-cavity mold is far more complex than scaling up a single cavity. It demands meticulous engineering:

Runner System Design & Balancing (The Heartbeat of Success)

This is arguably the most critical aspect. The runner system – the channels that deliver molten plastic from the injection unit sprue to each cavity gate – must be perfectly balanced.

Geometric Balancing: Cavities should be arranged symmetrically (e.g., radial, H-pattern, X-pattern) relative to the sprue. Unequal flow path lengths inherently cause imbalance.

Thermal Balancing: Ensuring all runners have identical thermal characteristics (cooling, heat retention) is vital. Variations cause plastic in different runners to flow at different viscosities and rates.

Consequences of Imbalance: Unbalanced filling leads to:

Some cavities filling faster than others.

Variations in part weight, dimensions, and mechanical properties.

Differences in shrinkage and warpage.

Potential for flash in some cavities and short shots in others.

Increased scrap rates and quality issues.

Gate Design

The gate (entry point to the cavity) must be carefully designed and sized for each cavity, often requiring fine-tuning to ensure consistent filling and packing pressure across all cavities. Hot runner systems are frequently employed in multi-cavity molds for greater control and reduced material waste.

Cooling System Design

Efficient and balanced cooling is paramount for consistent cycle times and part quality. Cooling channels must be strategically placed near every cavity to extract heat uniformly. Imbalanced cooling causes uneven solidification rates, leading to warpage and extended cycle times (dictated by the slowest-cooling cavity).

Ejection System

The mechanism to eject parts must reliably and simultaneously remove all parts from their cavities without damage. This requires robust design and precise alignment.

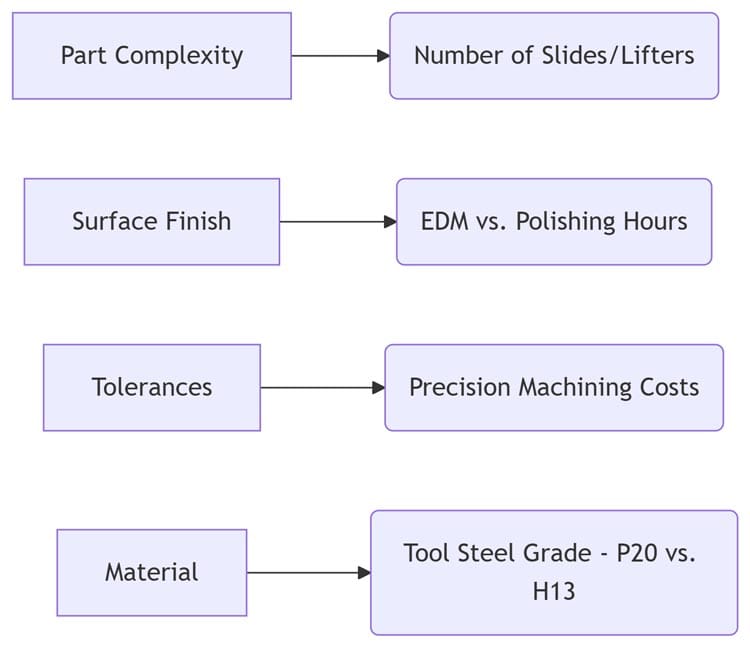

Mold Construction & Machining

Building a multi-cavity mold demands extremely high precision machining to ensure all cavities are geometrically identical. Any deviation between cavities translates directly into part variation. High-grade tool steels and advanced machining techniques (like EDM) are essential.

Mold Maintenance & Repair

Multi-cavity molds are complex and expensive. Maintenance is critical. Damage or wear in one cavity necessitates repair, potentially taking the entire mold (and its production capacity) offline. Spare components and skilled toolmakers are essential.

Part Complexity & Size:

While excellent for small-to-medium identical parts, highly complex or very large parts may not be suitable for high-cavitation molds due to space constraints within the mold base, immense clamping force requirements, and increased risk of imbalance.

Evolution & Advanced Concepts

Multi-cavity mold technology continuously evolves:

Family Molds: These contain cavities for different parts (e.g., a lid and a base) within the same mold. While not producing identical parts, they leverage the multi-cavity concept for producing complete assemblies in one cycle, reducing assembly steps. Balancing is even more challenging due to different part geometries and volumes.

High Cavitation: Modern manufacturing pushes cavity counts into the dozens or even hundreds for very small parts (e.g., micro-components, connectors). This demands extreme precision and sophisticated hot runner controls.

Conformal Cooling: Using 3D printing (Additive Manufacturing) to create cooling channels that perfectly follow the cavity contours, drastically improving cooling efficiency and uniformity in complex multi-cavity molds.

Advanced Simulation: Mold flow simulation software is indispensable. Engineers can virtually test runner designs, predict filling patterns, identify potential imbalances, and optimize cooling layouts before cutting steel, saving significant time and cost.

When Does Multi-Cavity Molds Make Sense?

Multi-cavity molds shine when:

Production Volumes are High: The cost savings per part must justify the higher initial mold investment.

Part Size is Small-to-Medium: Fitting numerous cavities into a standard mold base is practical.

Part Geometry is Suitable: Parts should be relatively simple or have consistent wall thicknesses to aid balanced filling.

Consistency is Paramount: Applications requiring tight tolerances and minimal part-to-part variation.

Material Cost is Significant: Reducing runner scrap (especially with hot runners) provides tangible savings.

Conclusion: The Indispensable Workhorse

The multi-cavity mold is not merely an option in high-volume plastics manufacturing; it is often the essential engine driving efficiency, cost-effectiveness, and scalability. It embodies the principle of doing more with less – less machine time, less energy per part, less labor cost per part. While demanding sophisticated design, precision engineering, and careful maintenance, the rewards in terms of production throughput and unit cost reduction are undeniable.

From the ubiquitous components in your car and smartphone to the specialized parts in life-saving medical devices, multi-cavity molds work tirelessly behind the scenes, shaping our material world one high-volume cycle at a time. They remain a testament to the ingenuity of manufacturing engineering, constantly evolving to meet the ever-increasing demands for speed, precision, and efficiency in the plastic age. Understanding their power and complexities is fundamental for anyone involved in bringing plastic products to market at scale.