Mastering Multi-Cavity Molds: Advanced Design Strategies for High-Yield Injection Molding

For manufacturers navigating the demands of high-volume plastic part production, multi-cavity molds represent far more than just multiple part replication. These sophisticated systems are precision-engineered ecosystems where fluid dynamics, thermal management, and mechanical synchronization converge to redefine manufacturing efficiency. When optimized, they deliver unparalleled ROI; when mismanaged, they become costly sources of scrap and downtime. Here’s how leading engineers are pushing the boundaries beyond conventional designs.

Table of Contents

Toggle

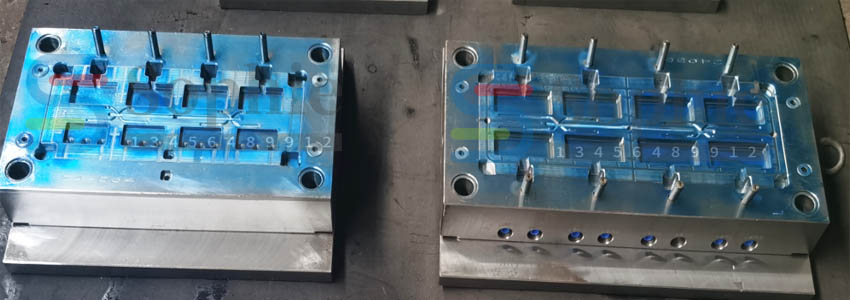

The Hidden Challenge: Flow Imbalance & Advanced Runner Optimization

While producing multiple parts per cycle seems straightforward, flow imbalance consistently undermines efficiency. Studies show that even a 5% filling variation between cavities can increase reject rates by up to 20%. The root causes extend beyond runner length asymmetry:

Shear-induced viscosity differentials: Faster-flowing melt in shorter runners experiences higher shear thinning, reducing viscosity and accelerating fill rates further.

Thermal hysteresis: Residual heat in manifolds causes later shots to enter cavities at higher temperatures, altering flow dynamics.

Geometric resonance: Certain cavity layouts (e.g., H-patterns) amplify pressure waves, creating feedback loops that destabilize filling.

Advanced Solutions:

Genetic Algorithm-Driven Designs: Researchers now use computational models to generate runner geometries that compensate for shear and thermal effects, achieving filling pressure variances below 2% across 32-cavity molds.

Melt Flippers: Strategically placed flow inversions in runners equalize shear history, preventing preferential filling in outer cavities。

Hot Runner Systems: Beyond Temperature Control

Modern hot runners like YUDO or HUSKY (cited in bottle preform molds) are neurological centers managing material behavior:

Per-cavity rheological control: Individual needle valve gates with PID-controlled zones adjust for material viscosity drifts during production runs.

Anti-drool architectures: For PVC applications (where thermal degradation begins at 195°C), closed-loop pressure sensors retract valve pins within 0.03 seconds of injection completion, eliminating degradation-prone residencies.

Table: Hot Runner Configuration Impact on Cycle Time & Quality

| System Type | Cycle Time Reduction | Scrap Rate | Material Savings |

|---|---|---|---|

| Cold Runner | Baseline | 3-8% | 0% |

| Standard Hot Runner | 12-18% | 1.5-4% | 15-25% |

| Valve-Gated Hot Runner | 20-30% | <1% | 28-40% |

Conformal Cooling & Additive Manufacturing

Traditional straight-drilled cooling channels leave thermal dead zones around complex geometries, causing differential shrinkage. The breakthrough?

3D-Printed Conformal Channels: Mold inserts with labyrinthine cooling paths following cavity contours achieve 40% faster heat extraction. For a PVC junction box mold, this reduced cycle times from 28s to 19s while eliminating warpage.

Diffusion-Bonded Stacks: Laminated plates with chemically etched flow paths enable uniform cooling in massive molds where 3D printing isn’t feasible

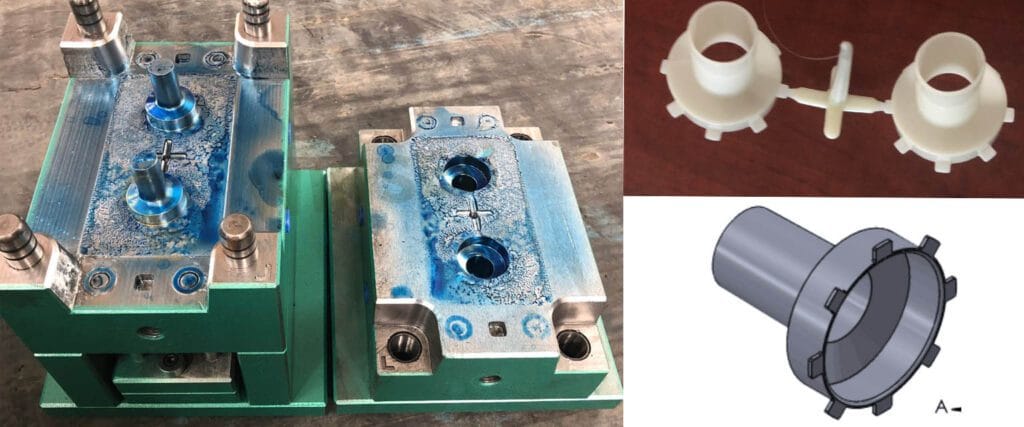

Family Molds: Multi-Product Synchronization

Producing disparate components (e.g., bottle caps and closures) in one mold introduces extreme flow complexity:

Volumetric Balancing: Using uniform design methodologies, engineers optimize runner diameters so that a 15g part and a 5g part fill simultaneously despite different flow resistances.

Pressure-Gradient Mapping: Sensors track melt front positions to dynamically adjust injection profiles, preventing overpacking in low-resistance cavities

Predictive Maintenance & Industry 4.0 Integration

With mold costs exceeding $250,000 for 96-cavity systems, proactive upkeep is non-negotiable:

Critical Maintenance Triggers:

Every 100,000 cycles: Replace valve gate seals, clean exhaust channels

Every 500,000 cycles: Recalibrate ejection systems, resurface cavity coatings

IoT-Enabled Degradation Monitoring:

Vibration sensors detecting misaligned ejector pins

Thermal cameras identifying hot runner zone drift

Flow sensors highlighting gate wear before flash defects occur

Material-Specific Cavitation Strategies

Not all polymers behave equally in high-cavitation environments:

PVC’s Thermal Sensitivity: Requires molds ≤ 48 cavities with oversized runners to maintain melt temps below 190°C and avoid HCl gas formation.

Semi-Crystalline Polymers (PP, PE): Demand symmetrical cavity layouts to ensure uniform crystallization – asymmetric cooling induces warpage.

Engineering Resins (PEEK, PPS): Utilize cavity-specific thermal profiles where gate regions run hotter than overflow areas to prevent premature freezing.

The Future: AI-Optimized Mold Ecosystems

Leading molders now deploy closed-loop learning systems:

Real-Time Melt Simulators: Moldex3D-integrated presses adjust shot profiles mid-cycle based on cavity pressure data.

Self-Balancing Hot Runners: Machine learning algorithms analyze historical scrap patterns to autonomously adjust gate timings and temperatures.

Implementation Roadmap: When to Scale Cavitation

| Part Criteria | Recommended Cavities | Key Enablers |

|---|---|---|

| Micro-parts < 2g | 64-128 | Micro-gating (<0.3mm), vacuum venting |

| Thin-wall containers (preforms) | 32-96 | Valve-gated hot runners, conformal cooling |

| Engineering resin components | 8-16 | Individual cavity temperature control |

| PVC/thermosensitive materials | 16-48 | Low-shear runners, dedicated thermal buffers |

Conclusion: Precision as the New Efficiency

The era of simply adding cavities for volume is over. Next-generation multi-cavity molds are cyber-physical systems where thermal, rheological, and mechanical variables are continuously optimized. Success demands:

Front-Loaded Simulation: Leverage Moldflow or Moldex3D to predict imbalances before cutting steel .

Additive-Enabled Tooling: Adopt conformal cooling as standard for cycle time reduction.

Predictive Intelligence: Treat mold maintenance as a data science challenge, not reactive repairs.

For OEMs mastering this convergence, multi-cavity injection molds deliver more than parts – they become sustainable competitive advantages, slashing energy use per unit by up to 35% while achieving Six Sigma quality at automotive scales. The future belongs to molds that don’t just produce faster, but smarter.