Nylon PA66+30% glass fiber injection mold steel and process parameters full analysis

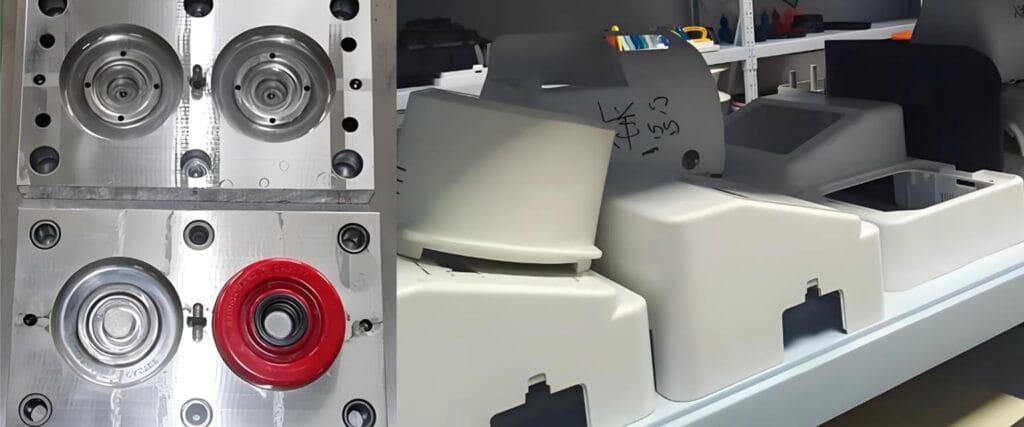

Nylon PA66 30% glass fiber injection mold is very important injection mould.In the field of engineering plastic injection molding, nylon PA66 plus 30% glass fiber reinforced material (PA66+30%GF) is popular for its excellent mechanical properties, heat resistance and dimensional stability. However, this high glass fiber content composite material puts forward special requirements for mold steel and molding process. This article will introduce in detail the mold steel selection, temperature control parameters and molding process points of PA66 injection mold and PA66+30% glass fiber injection mold, helping you optimize the production process and improve product quality.

Table of Contents

ToggleWhat is PA66 material?

PA66 is a polyamide polymer material, also known as nylon 66, which is a polymer material obtained by polymerization of caprolactam and suberic acid. PA66 has excellent heat resistance, wear resistance, corrosion resistance and mechanical strength, and is widely used in automobiles, electronics, machinery and other fields.

PA66+30%GF material properties and mold requirements

Material properties

- High strength and high rigidity: 30% glass fiber reinforcement significantly improves the tensile strength and bending modulus of the material

- Excellent heat resistance: heat deformation temperature (HDT) can reach above 250°C

- Good dimensional stability: low shrinkage, but anisotropic shrinkage

- High wear resistance: glass fiber has strong wear on molds and injection molding machine screws

Special requirements for PA66 injection molds

- High wear resistance: need to resist the wear of glass fiber

- Good thermal conductivity: ensure fast and uniform heat exchange

- High hardness: maintain long-term dimensional accuracy of the mold

- Corrosion resistance: prevent corrosion from acidic substances released by glass fiber

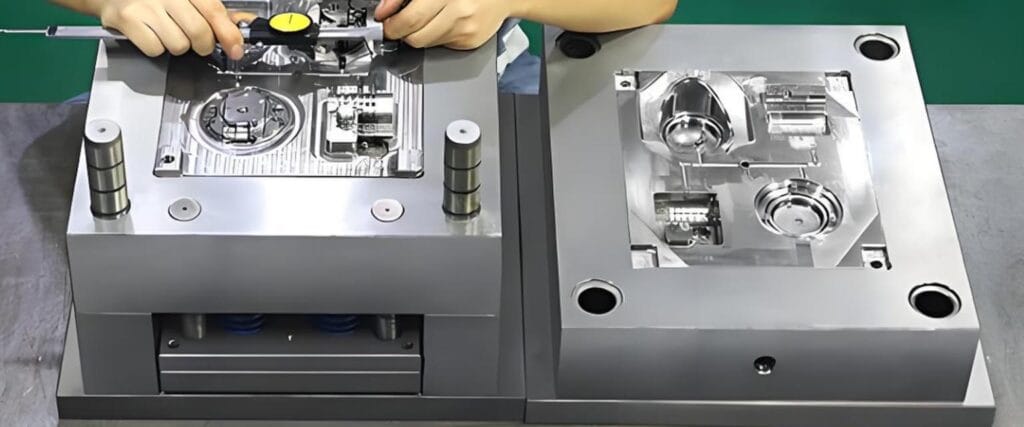

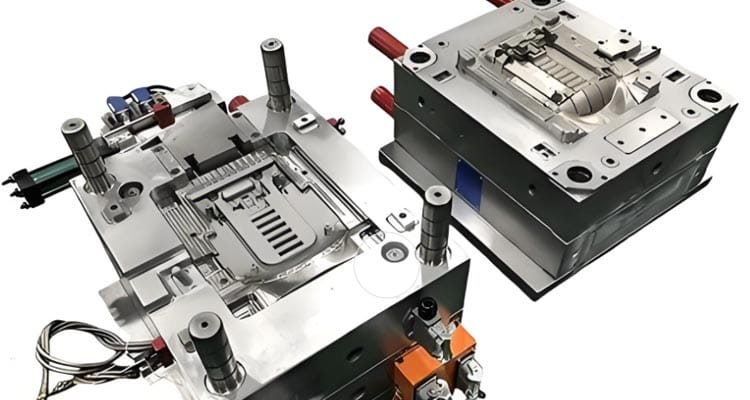

PA66+30%GF Injection Mold Recommended Steel

For injection molds of nylon PA66+30% glass fiber reinforced materials, it is generally recommended to use high-quality mold steel, such as P20 steel, 718 steel,1.2738,H13 etc. These steels have high hardness, toughness and corrosion resistance, and can meet the manufacturing requirements of molds. At the same time, it is necessary to pay attention to the quality and performance of the steel to ensure the manufacturing quality and cost of the mold. It is recommended that you consult a professional mold manufacturer or steel supplier to obtain more accurate information.

What is the injection mold temperature of nylon PA66 +30% glass fiber

Generally speaking, for nylon PA66 + 30% glass fiber reinforced materials, the melting point is generally around 250°C and the decomposition temperature is above 300°C.

During the injection molding process, it is necessary to determine the appropriate injection molding temperature according to the specific mold structure and the shape and size of the plastic product. Generally speaking, too high an injection molding temperature will lead to problems such as material decomposition, bubbles, and sintering, while too low an injection molding temperature will lead to problems such as rough surface, shrinkage, and warping of the molded product. Therefore, it is necessary to adjust according to the actual situation to ensure the quality and production efficiency of the molded product.

In short, the injection molding temperature of nylon PA66 + 30% glass fiber reinforced materials needs to be adjusted according to factors such as specific materials and mold structures. Generally, it should be above the melting point of the material but not exceed the decomposition temperature. At the same time, it is also necessary to pay attention to the influence of other factors on the injection molding process to ensure the quality and production efficiency of the molded product. It is recommended that you consult a professional injection molding engineer or mold manufacturer for more accurate information.

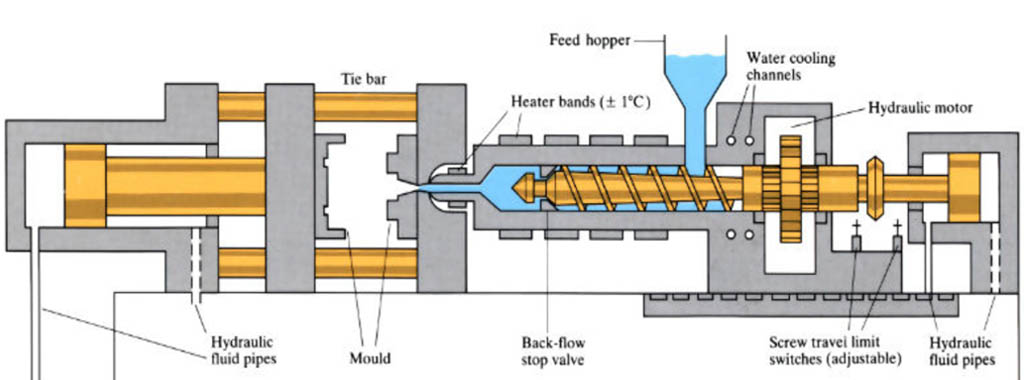

Key points of PA66+30% GF injection molding process

Recommended injection molding parameters

- Injection speed: medium-high speed (to avoid excessive orientation of glass fiber)

- Holding pressure: 50-70% of maximum injection pressure

- Back pressure: 5-15bar

- Screw speed: 50-80rpm

Mold design considerations

- Gate design:Preferably use fan-shaped gate or latent gate; Avoid using pin-point gate; Gate size should be 20-30% larger than ordinary PA66

- Vent system: Vent groove depth 0.02-0.03mm; Set one vent point for every 100mm².

- Ejector system: Increase the number of ejector pins; Use nitrided ejector pins; Consider gas-assisted ejection

Common problems and solutions

Surface floating fibers: Low melt temperature, Increase material temperature by 10-20°C;

Dimensional instability; Uneven mold temperature, Check the mold temperature controller water circuit

Mold wears quickly: Insufficient steel hardness, Replace with higher hardness steel

Difficult demoulding: Insufficient mold polishing ,Perform mirror polishing

Mold maintenance and care recommendations

Daily maintenance

Check mold wear every 5,000 molds

Clean the exhaust groove regularly

Use special rust inhibitors

Long-term maintenance

Professional polishing every 3-6 months

Check mold hardness every year

Establish mold usage records

In conclusion

PA66+30% glass fiber injection molding is a technology that has high requirements for molds and processes. Selecting the right mold steel (such as 1.2738 or H13), strictly controlling the barrel temperature (280-300°C) and mold temperature (80-120°C), and optimizing the injection molding parameters can ensure the production of high-quality products. For PA66 injection mold and PA66+30% glass fiber injection mold, it is recommended to cooperate with experienced mold manufacturers to obtain the best production efficiency and product quality.

If you need to further optimize your PA66+30% GF injection molding process, please consult our professional technical team, we will provide you with a one-stop solution from mold design to molding