Plastic Injection Chair Mold Manufacturer Professional Solutions

Premium Plastic Chair Injection Molds Manufacturing,Fast cycle time

Precision Chair Molds Enhance Your Plastic Chair Manufacturing Efficiency

WS Mould Co., Ltd. provides an all-inclusive service package for top-tier Plastic Injection Chair Moulds. From initial concept and design of plastic chairs, through mould engineering and tooling, to injection moulding expertise and beyond, we cover every aspect you need. Let us streamline your operations, so you can focus on growing your business and producing exceptional plastic chairs.

Trustworthy Plastic Chair Mould Injection Services Solutions

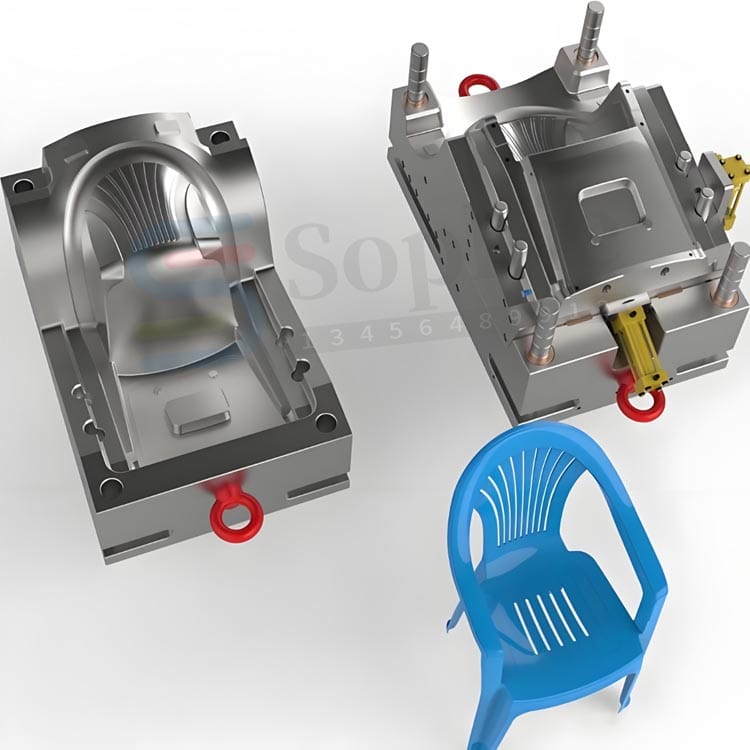

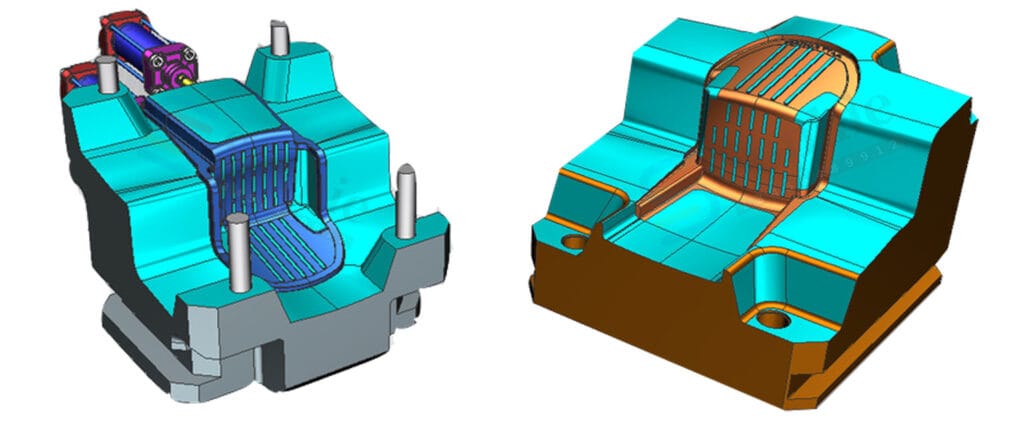

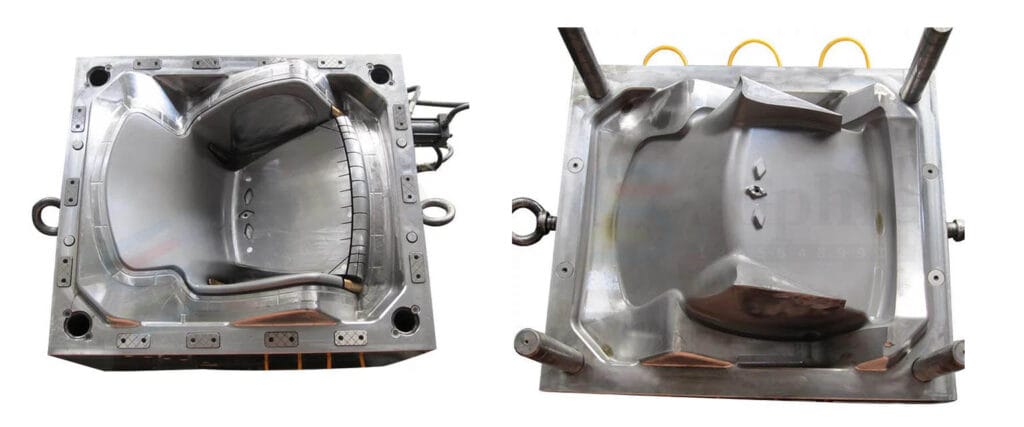

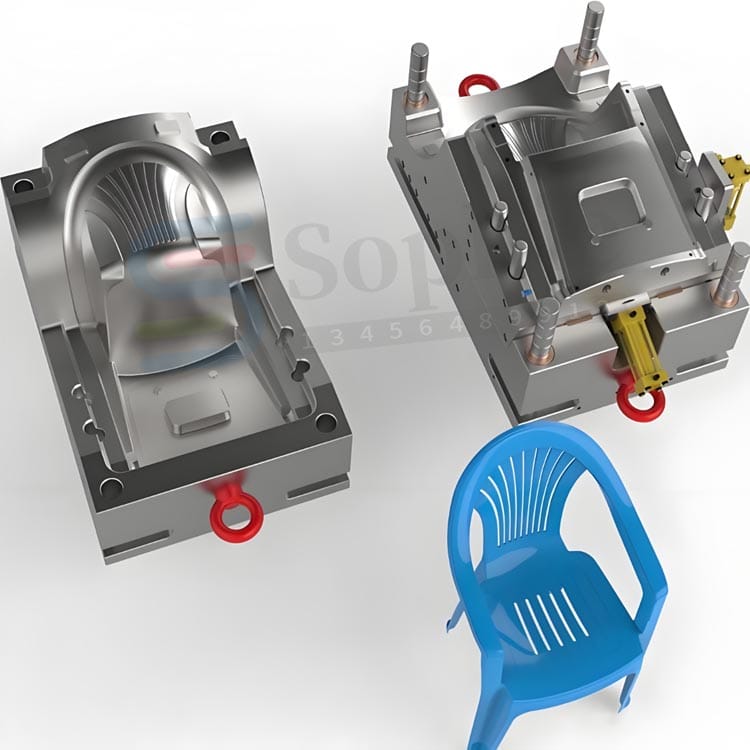

A chair mold, specifically a plastic chair mold, is a precision-engineered tool used in the injection molding process to shape molten plastic into durable, functional, and aesthetically pleasing chair parts. These molds are essential for mass production, enabling manufacturers to create consistent and high-quality plastic chairs efficiently. The type of mold used directly influences the chair’s design, functionality, durability, and production efficiency

Plastic Injection Chair Mould

PP Chair Injection Molding Mould

High Quality Daily necessities Chair Mold

Plastic Injection Chair Mould Maker | Precision Moulding Techniques

Plastic Injection Chair Mould Production

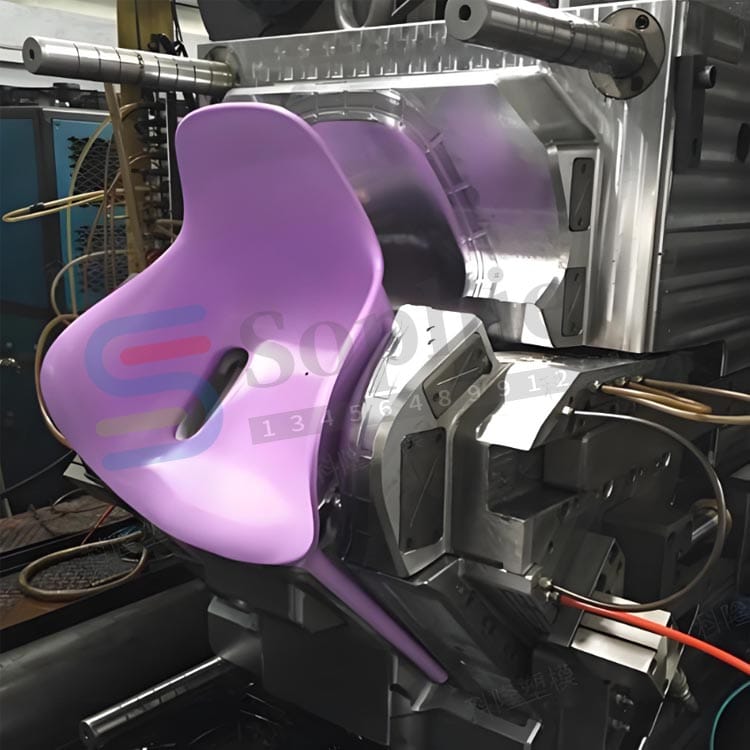

Plastic Injection Chair Mold Manufacturing is a process typically involves heating plastic pellets until they melt, injecting them into a carefully designed mold, and then allowing the material to cool and solidify. Injection molding allows for precise shapes and consistent wall thickness, making it ideal for intricate product designs. For more complex chair designs, gas-assisted injection molding can be employed, creating hollow sections that result in lighter products without sacrificing strength.

Advanced quality control measures, such as Duplicate Production Inspection (DUPRO) and pre-shipment inspections, ensure that the chairs meet high standards for aesthetics and structural integrity. Regular assessments of mold design and material properties are necessary to maintain the chairs’ high quality.

In summary, a chair mold is a critical tool in the production of plastic chairs, offering flexibility in design, high production efficiency, and the ability to create durable and aesthetically pleasing products. The choice of mold type depends on factors such as production goals, budget, and design complexit.

A wide variety of plastic chair moulds can be provided

- Arm Chair Molds

- Armless Chair Mouds

- Dinner Chair Molds

- Children Chair Molds

- Plastic Rattan Chair Moud

- Foldable Chair Molds

- Art Chair Molds

- Bus Chair Mods

- Office Chair Molds

- Household Chair Mold

Can’t Find the Right Plastic Chair Mould? Struggling to locate the perfect plastic chair mould for your project? Reach out to us immediately! Our seasoned sales engineers are on standby to provide prompt responses. We excel in crafting a wide array of plastic chair moulds to meet your specific needs.

Premium Plastic Chair Mould Features Showcase

- Precision Parting Lines: Ensuring seamless and clean edges.

- Optimized Structure: Including strategically placed sliders for arms, ejector pins, and efficient air venting.

- Advanced Design: Incorporating features like gas-assisted molding for enhanced durability and aesthetics.

- Modular Inserts: Interchangeable chair back inserts allow for multiple backrest designs while keeping costs in check.

Plastic Chair Mould Solutions from China

What Constitutes the Materials for Injection Molding of Plastic Chairs?

A variety of plastic materials are employed in the injection molding process for creating chairs. Common choices include Polypropylene (PP), Polyethylene (PE), and Acrylonitrile Butadiene Styrene (ABS). These materials are known for their strength, flexibility, and ability to withstand stress.

Polypropylene is particularly popular because of its lightweight nature, strength, and cost-effectiveness. It also has excellent resistance to heat and moisture, making it suitable for outdoor applications. Polyethylene is another suitable option for crafting resilient and durable chairs. ABS is chosen when greater strength and a glossy finish are desired. Occasionally, recycled plastics are also utilized to manufacture eco-friendly chairs.

The selection of material depends on the intended use of the chair and the level of durability required. Experts can assist in determining the most appropriate plastic for specific applications.

A plastic chair injection mold shapes molten plastic into chair forms, akin to a chair-specific cookie cutter. The process involves melting plastic into a liquid state, which is then poured into the mold. Once cooled, the plastic solidifies into a chair.

Constructed from sturdy metals like steel or aluminum, these molds are designed for repeated use, ideal for producing large quantities of identical chairs efficiently and cost-effectively.

Why choose our plastic injection molding chair molds?

In plastic injection chair molds production, plastic injection molding chair molds offer the following advantages:

High-precision manufacturing

Modern manufacturing technology ensures high mold precision, guaranteeing accurate chair dimensions and clear details.

Fast production cycle

Mold design and manufacturing processes can be completed quickly, shortening the product’s timeline from design to market.

High durability

High-quality mold materials and advanced surface treatment technologies result in a longer mold lifespan, reducing replacement frequency and maintenance costs.

High adaptability

Molds can be quickly adjusted to accommodate chairs of different designs or sizes, improving production flexibility.

Cost control:

Through precise material calculations and effective production management, mold production costs can be effectively controlled.

Quality control

Strict quality control processes ensure that each mold meets high standards, reducing the defect rate.

Modular design

Molds can be designed in a modular fashion, facilitating replacement and upgrades to adapt to new production needs.

Technical support

A professional technical support team can provide full-process services from design to production to ensure the smooth progress of mold production.

Plastic chairs are ubiquitous, gracing the interiors of homes, educational institutions, workplaces, and outdoor spaces. They’re favored for their lightweight design, durability, and ease of maintenance. But what’s the secret behind their creation? A prevalent and efficient technique involves the use of injection molding machinery specifically designed for chair production. This approach not only accelerates the manufacturing process but also keeps costs down, all while ensuring the chairs are robust and reliable.