What Is Plastic Injection Molding

Plastic injection molds represent the convergence of metallurgy, fluid dynamics, and digital innovation.Plastic injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure. Once the plastic cools and solidifies, the mold opens, and the finished part is ejected. This process is highly repeatable, allowing for mass production of identical plastic components with tight tolerances.

Table of Contents

ToggleEvery day, you interact with dozens of products born from a technological marvel: the plastic injection mold. From your toothbrush to automotive dashboards and life-saving medical devices, injection molds silently shape our world. This comprehensive guide reveals why this manufacturing process dominates global production – and how to leverage it for your projects.

What Makes a Mold

Core & Cavity: Precision-machined steel/aluminum blocks forming the part’s shape

Runner System: Channels guiding molten plastic to cavities

Ejection Pins: Forced removal of cooled parts

Cooling Channels: Critical temperature control system

Venting: Prevents air traps and burn marks

Key Components of a Plastic Injection Mold

Injection Unit – Melts and injects the plastic material into the mold.

Mold (Tool) – A precision-machined metal cavity that shapes the plastic part.

Clamping Unit – Holds the mold halves together during injection and cooling.

Ejection System – Pushes the finished part out of the mold after cooling.

Types of Plastic Injection Molds

Classification by Structure

Two-Plate Molds: Most basic and economical design

Three-Plate Molds: Allow automatic separation of runner system

Hot Runner Molds: Eliminate material waste from runners

Stack Molds: Double production capacity without larger machines

Specialized Mold Types

Overmolding: Combines multiple materials in one cycle

Insert Molding: Encases metal or other components in plastic

Micro Molding: For extremely small, high-precision parts

Gas-Assisted Molding: Creates hollow sections with internal gas channels

How Injection Molding Works

Cycle Breakdown (Typical 15-60 sec)

Clamping: 2,000+ tons force seals mold

Injection: Molten plastic (180-300°C) injected at 1,500+ psi

Packing: Additional material compensates for shrinkage

Cooling: 80% cycle time – determines part warpage

Ejection: Robotic arms remove finished parts

Critical Parameters

- Melt Temperature: ±5°C variance causes defects

- Injection Speed: Impacts surface finish & internal stresses

- Cooling Rate: Governs crystallinity & mechanical properties

- Hold Pressure: Prevents sink marks and voids

Material Matters – Engineering Your Polymer

Top Injection Molding Polymers

ABS: Electronics housings (impact resistance)

Polypropylene (PP): Medical devices (sterilizable)

Polycarbonate (PC): Bulletproof glass (optical clarity)

PEEK: Aerospace (high-temp performance)

TPE/TPU: Ergonomic grips (flexibility)

| Material | Characteristics | Typical Applications |

|---|---|---|

| ABS | Tough, impact-resistant | Automotive parts, toys |

| Polypropylene | Chemical resistant, flexible | Food containers, living hinges |

| Polycarbonate | Transparent, high impact | Safety glasses, bullet-resistant windows |

| Nylon | Wear-resistant, strong | Gears, bearings |

| PEEK | High temperature resistance | Aerospace, medical implants |

Material Selection Checklist

☑ End-use temperature ☑ Chemical exposure ☑ Regulatory compliance (FDA, UL94)

☑ Impact resistance ☑ Cost/kg ☑ Recyclability

Design Rules for Mold Success

Avoid Costly Mistakes

Uniform Wall Thickness: (Ideal: 1-3mm) Prevents sink marks

Draft Angles: Minimum 1° per side for clean ejection

Radii Edges: >0.5mm reduces stress concentration

Boss Design: Use ribs to prevent sink around attachments

Gate Location: Impacts weld lines and cosmetic appearance

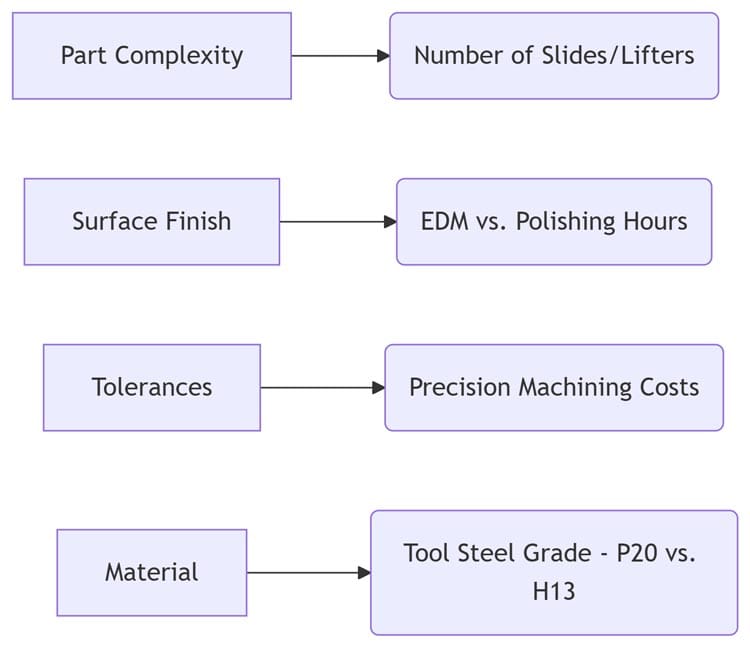

Tooling Cost Drivers

Since excess material can often be reused, compression molding is more sustainable than other methods.

Advanced Applications – Where Molds Make History

Medical:

Micro-molding of <0.1g catheter components

Cleanroom molds with ISO Class 8 certification

Automotive:

72-hour mold changes for just-in-time production

In-mold electronics for dashboard integration

Sustainability Frontiers:

Biodegradable PLA molds for compostable packaging

Gas-assist molding reducing material use by 40%

The Future of Mold Technology

Industry 4.0 Integration:

AI-driven predictive maintenance on molds

Real-time pressure/temperature sensors with IIoT

Digital twin simulation for zero-defect launch

Emerging Techniques:

Conformal Cooling: 3D printed molds with organic channels (↓ cycle time 30%)

Mold-in-Color: Eliminating painting process

Hybrid Molds: Combining metal 3D printing and CNC machining

Advantages of Plastic Injection Molding

High Efficiency: Rapid production of thousands of identical parts

Design Flexibility: Complex geometries achievable

Material Variety: Wide range of compatible plastics

Cost Effectiveness: Low per-part cost at high volumes

Precision and Repeatability: Tight tolerances (±0.005 inches achievable)

Minimal Waste: Excess material can often be reground and reused

More Than Just Tooling – Your Competitive Edge

Plastic injection molds represent the convergence of metallurgy, fluid dynamics, and digital innovation. As additive manufacturing advances, traditional molds evolve rather than disappear – becoming smarter, faster, and more sustainable. Whether you’re developing a medical device or consumer product, mastering mold design principles delivers:

✓ 10-30% material cost savings

✓ 50%+ reduction in secondary operations

✓ Production rates of 1,000+ parts/hour

✓ Micron-level precision unattainable by other processes

The mold isn’t just a tool – it’s the physical manifestation of your product’s DNA. Partner with experienced mold engineers early in development to unlock manufacturing excellence.

“Give me the right mold, and I’ll give you a perfect part – every 15 seconds, for a million cycles.”

– Veteran Tooling Engineer, Shenzhen

Looking to develop your injection molded product?

[Contact our design team for a free DFM (Design for Manufacturability) analysis]