Advanced Compression Molding Thermoset Mold Solutions

Advanced Compression Molding Thermoset Mold Solutions for High-Performance Composites.WS MOLD specializes in advanced thermoset mold solutions. Through cutting-edge compression molding technology, it provides lightweight, durable and high-temperature resistant parts manufacturing capabilities for various industries.

Table of Contents

Toggle

The temperature range of thermosetting molds is usually between 120°C and 200°C, depending on the specific material and application. Proper mold temperature control ensures that the resin is fully cured and cross-linked, ensuring dimensional accuracy and mechanical strength, minimizing surface defects and flash, and extending mold life and reducing maintenance costs.

What is a thermoset mold

A thermoset mold is a tool specifically used to manufacture products made from thermoset polymers. Unlike thermoplastics, which can be repeatedly heated and reshaped, thermosets undergo an irreversible chemical curing process under high temperature and pressure. This results in the finished product possessing excellent dimensional stability, chemical resistance, and mechanical properties.

At WS MOLD, we design and manufacture thermoset molds with high precision, ensuring their reliability in demanding applications.

Advantages of Thermoset Molding

- Dimensional Stability: After curing, thermoset parts retain their shape under thermal and mechanical stresses.

- Electrical Insulation: Phenolic and epoxy thermosets offer excellent insulation, making them ideal for electrical enclosures.

- Chemical Resistance: Oil, solvent, and corrosion resistant, suitable for harsh environments.

- Lightweighting Alternative: Thermoset composites offer reduced weight while maintaining strength, particularly in the automotive and aerospace sectors.

- Cost-Effectiveness: Compression molding tools enable cost-effective mass production of complex parts.

Common Thermoset Mold Processes

Different molding processes utilize thermoset molds to achieve high-quality production:

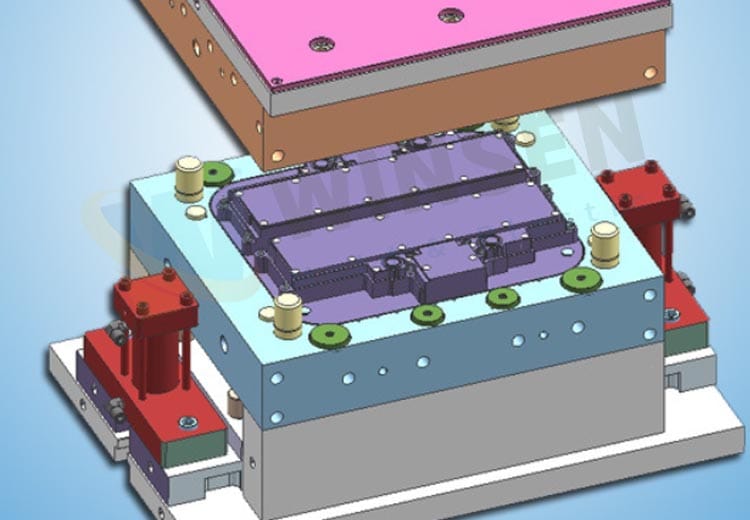

- Compression molding: The most common method involves placing a pre-measured amount of material into a heated compression mold and curing it under pressure. It is suitable for automotive structural parts and appliance housings.

- Transfer molding: Material is preheated and then pressed into the mold cavity. This allows the production of parts with complex designs and inserts, such as connectors and packaging.

- Thermoset injection molding: Suitable for high-volume production of small, precision parts, such as switches, sockets, and handles.

Industrial Applications of Thermoset Mold Technology

Thermoset molds provide durable, heat-resistant, and stable parts for various industries:

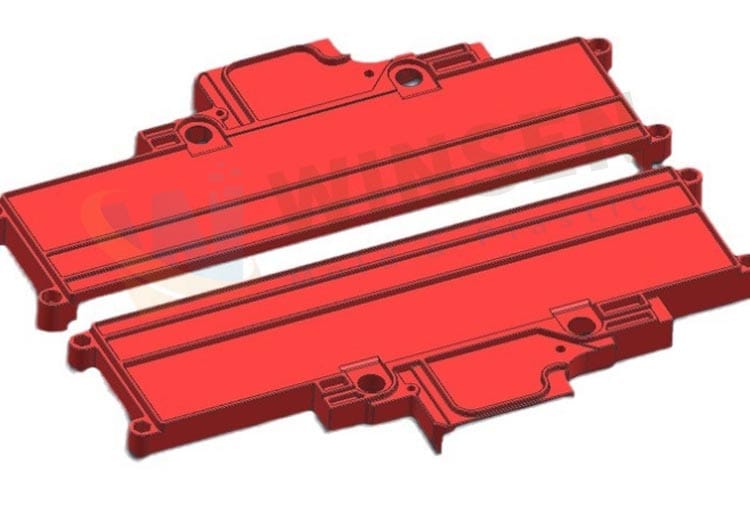

- Automotive: Brake pistons, clutch components, battery covers, and lightweight structural panels.

- Electrical: Switch housings, connectors, and insulation components with excellent dielectric strength.

- Aerospace: Lightweight structural and high-temperature-resistant parts for high-performance aircraft.

- Consumer: Kitchen appliances, appliance handles, and high-gloss decorative parts.

Key Design Considerations for Thermoset Molds

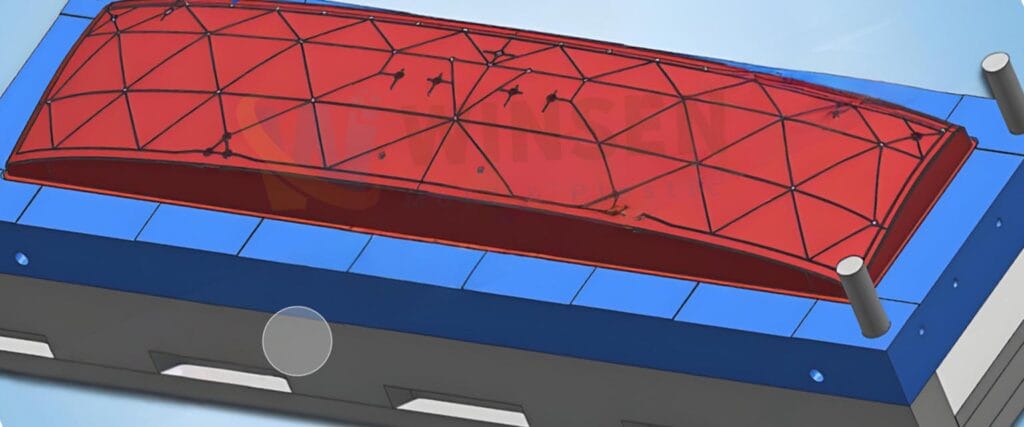

High-performance thermoset molds require precise engineering:

- Mold Material: Utilize wear-resistant tool steel with excellent thermal conductivity.

- Surface Treatment: Polish the mold cavity to reduce adhesion and ensure smooth demolding.

- Venting Design: Optimized venting channels release gases during the curing process.

- Temperature Control: Integrated heating systems ensure uniform curing.

- Automation Compatibility: Designed with robotic operation and efficient production cycles in mind.

The Future of Thermoset Molding

As demand for lightweight composites continues to grow in electric vehicles, aerospace, and renewable energy, thermoset tooling will continue to play a key role in advanced manufacturing. By 2030, innovations in carbon fiber-reinforced thermosets and hybrid composite tooling will further enhance cost-effectiveness and sustainability.

WS MOLD's expertise in thermoset moulds

At WS MOLD, we offer a complete suite of mold solutions for thermoset composites, including:

- SMC molds (sheet molding compound molds)

- BMC molds (bulk molding compound molds)

- Compression molding and Hot pressing mold

- FRP and carbon fiber molds for advanced composite manufacturing

By integrating precision engineering with modern automation, Shuangsheng provides reliable, efficient, and scalable thermoset mold solutions to customers worldwide.

Conclusion

Thermoset molds are more than just tools; they are the key to high-performance, durable, and lightweight composite manufacturing. With WS MOLD’s expertise, global industries can efficiently produce thermoset parts for the automotive, aerospace, electrical, and consumer sectors, contributing to a sustainable manufacturing future.