Bulletproof Ballistic Protection Armor Plate Compression Solutions

In today’s increasingly uncertain global security environment, the demand for high-performance bulletproof armor plates has surged, especially in conflict zones like Ukraine. To meet this demand, advanced manufacturing techniques such as compression molding are essential in producing reliable bulletproof armor plate molds. These bulletproof molds are crucial for creating lightweight yet ultra-strong ballistic protection using materials like Aramid (Kevlar) and UHMWPE (Ultra-High Molecular Weight Polyethylene).

Table of Contents

ToggleThis blog explores the importance of bulletproof armor plate molds, the manufacturing process, and why Ukraine is turning to high-quality tactical armor plate molds for enhanced defense solutions.

Understanding Bulletproof Armor Plate Molds

A bulletproof armor plate mold is a specialized tool used in the production of ballistic plates that can withstand high-velocity projectiles. These molds are designed to shape and compress advanced materials like Aramid (Kevlar) and UHMWPE (PE) into rigid or flexible armor plates.

Types of Armor Plate Molds:

- Bulletproof Armor Plate Compression Mold: Used in high-pressure molding to create dense, impact-resistant plates.

- Aramid (Kevlar) UHMWPE Bulletproof Plate Mold: Optimized for hybrid composites, combining Kevlar’s tensile strength with UHMWPE’s lightweight properties.

- Tactical Armor Plate Mold: Designed for military and law enforcement applications, ensuring mobility and protection.

- Compression Molding Bulletproof Ballistic Plate Mould: A cost-effective method for mass-producing standardized armor plates.

These molds must meet stringent ballistic standards (NIJ Level III, IV, or STANAG 4569) to ensure reliable protection against bullets, shrapnel, and other ballistic threats.

The Role of Compression Molding in Armor Plate Production

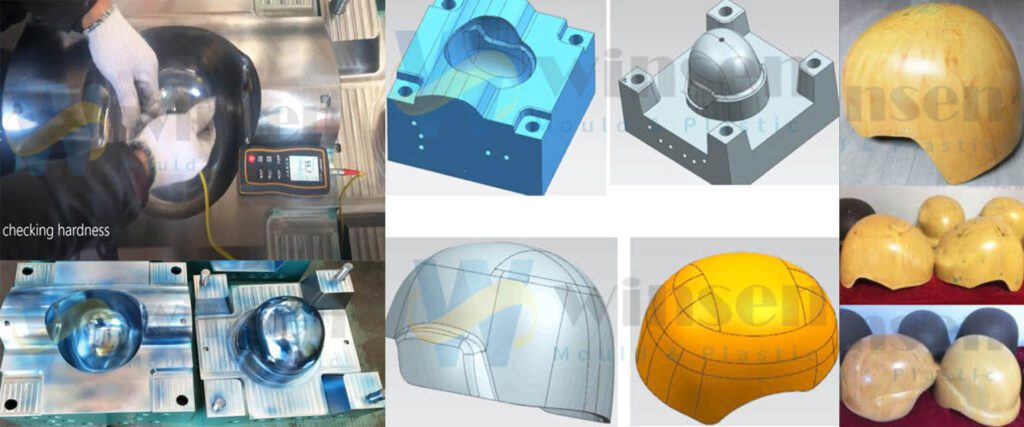

Compression molding is the most efficient method for manufacturing bulletproof ballistic plates. The process involves:

- Material Preparation: Layers of Aramid (Kevlar) or UHMWPE are stacked in the mold.

- High-Pressure Compression: The mold is subjected to extreme heat and pressure (up to 300°C and 1000+ psi), fusing the materials into a solid plate.

- Cooling & Finishing: The molded plate is cooled, trimmed, and tested for ballistic resistance.

Advantages of Compression Molding:

- Consistency: Ensures uniform density and strength across all plates.

- Cost-Effectiveness: Ideal for large-scale production.

- Customization: Molds can be adjusted for different thicknesses and shapes (e.g., curved plates for tactical vests).

Why Ukraine Needs High-Quality Armor Plate Molds

With ongoing conflicts, Ukraine requires advanced bulletproof armor plate molds to produce:

- Military-Grade Ballistic Plates (NIJ Level IV for rifle protection).

- Lightweight UHMWPE Plates for mobility in combat.

- Multi-Threat Armor capable of stopping bullets, fragments, and explosions.

By sourcing bulletproof armor plate compression molds, Ukraine can enhance domestic production of ballistic protection, reducing reliance on foreign suppliers and ensuring faster deployment to frontline troops.

Key Materials: Aramid (Kevlar) vs. UHMWPE

Aramid (Kevlar) Armor Plate Molds

- High tensile strength – excellent for stopping bullets.

- Heat resistant – maintains integrity under fire.

- Used in military helmets, vests, and vehicle armor.

UHMWPE (PE) Ballistic Armor Plate Molds

- 50% lighter than steel – ideal for mobility.

- High impact absorption – stops high-velocity rounds.

- Used in tactical plates for special forces.

Hybrid molds combining Aramid and UHMWPE offer the best balance of weight and protection.

Choosing the Right Tactical Armor Plate Mold Supplier

When selecting a bulletproof armor plate mold manufacturer, consider:

- Innovative high-efficiency production technology.

- Custom Mold Design (curved, multi-hit capable plates).

- Production Capacity (ability to meet large orders).

- Material Expertise (experience with Aramid & UHMWPE).

Leading suppliers offer compression molding bulletproof ballistic plate moulds with precision engineering for maximum durability.

Strengthening Ukraine’s Defense with Advanced Armor Plate Molds

As Ukraine continues to face security challenges, investing in bulletproof armor plate molds is critical for producing high-performance ballistic protection. Whether using Aramid (Kevlar), UHMWPE, or hybrid composites, compression molding remains the most efficient manufacturing method.

By securing reliable tactical armor plate molds, Ukraine can equip its military and law enforcement with lightweight, durable, and life-saving armor—ensuring better protection against modern ballistic threats.

For defense manufacturers and suppliers, now is the time to support Ukraine with advanced bulletproof armor plate compression molds—because every plate molded could mean a life saved.

Interested in high-quality armor plate molds? Contact us today for Aramid (Kevlar) UHMWPE ballistic armor plate compression molds tailored to your needs!