Table of Contents

ToggleInnovation and breakthrough | WS MOLD launches new BMC fence capping mold solution

BMC Fence Wall Cap Coping Mold professional maker in China. In the field of construction and landscape engineering, fences are not only a barrier for safety protection, but also an important part of aesthetic design. In order to meet the market demand for high-strength, weather-resistant, and diversely shaped fence caps (Fence Wall Cap/Coping), WS MOLD successfully developed and mass-produced BMC (Bulk Molding Compound) by compression molding fence capping molds. This fence wall cap coping mold uses advanced composite material molding technology to provide a more efficient and economical production solution for the construction industry.

What is a BMC wall capping mold?

Introduction to BMC materials

BMC (Bulk Molding Compound) is a fiber-reinforced thermosetting composite material composed of unsaturated polyester resin, glass fiber, fillers and additives. Its features include:

✔ High strength & high rigidity – suitable for load-bearing structures

✔ Corrosion resistance & weather resistance – UV resistance, acid and alkali resistance, suitable for outdoor use

✔ Fire retardant – in line with building safety standards

✔ Dimensional stability – no deformation after long-term use

✔ High surface finish – reduce post-processing

Application of BMC wall capping mold

Wall cap/coping is a covering installed on the top of the wall. Its main functions include:

- Waterproof and anti-seepage: prevent rainwater from penetrating and extend the life of the wall

- Safety protection: prevent climbing and enhance safety

- Beautiful decoration: enhance the overall visual effect of the building

Traditional wall capping mostly uses prefabricated concrete or natural stone, but there are problems such as heavy weight, complex installation and high cost. BMC compression molding technology can produce lightweight, high-strength, and diversified wall capping designs, greatly reducing transportation and installation costs.

The core advantages of our BMC wall capping mold

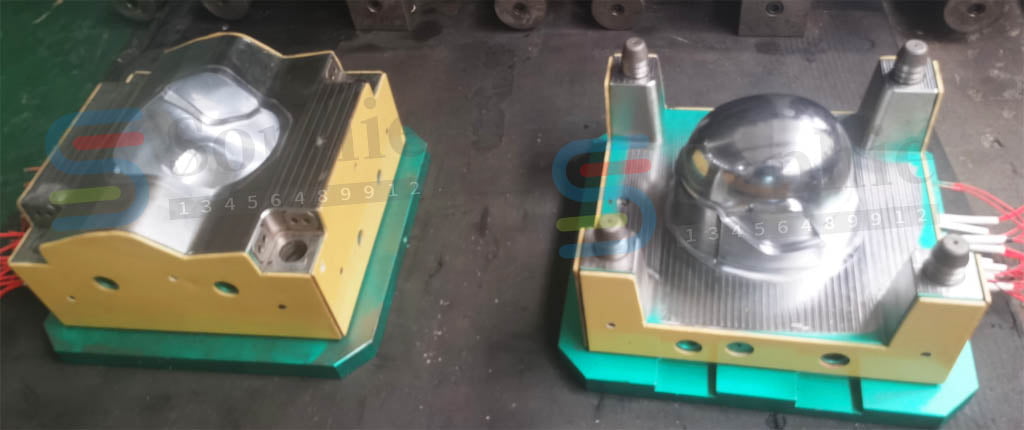

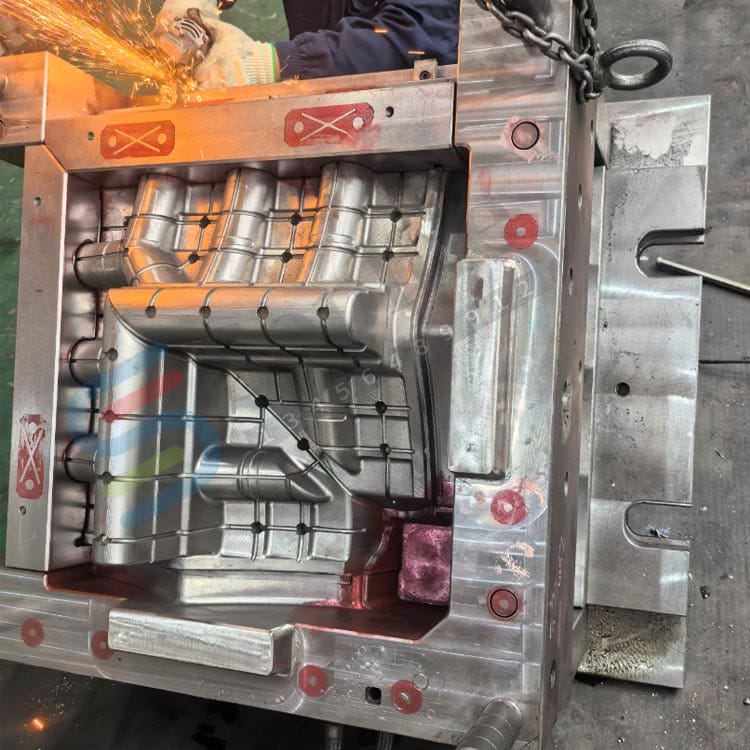

High-precision mold design

- Adopt CNC precision processing to ensure that the product size error is ≤0.1mm

- Optimize the flow channel design, reduce material waste, and improve production efficiency

- Support complex curved surface modeling to meet various architectural styles such as European, modern, and simple

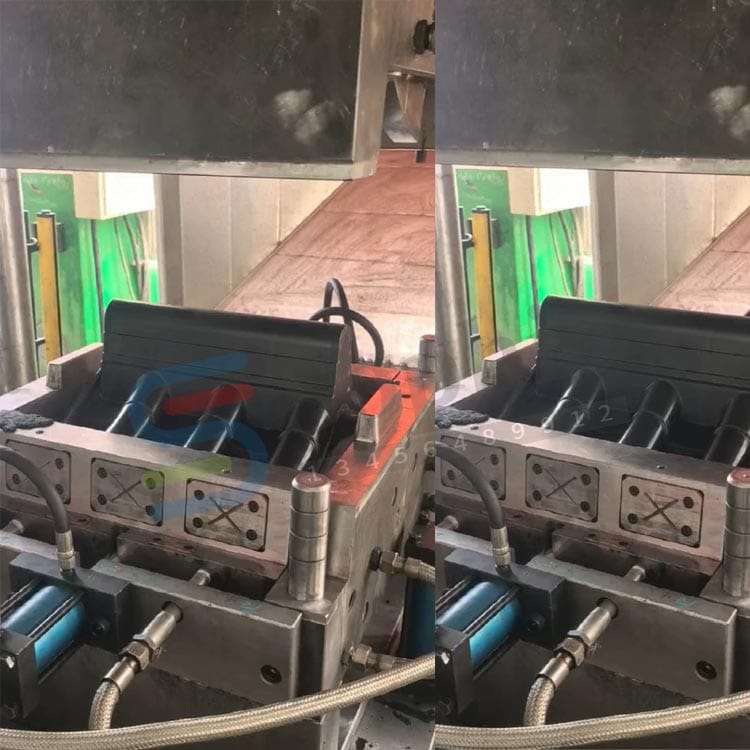

Rapid prototyping & high production capacity

- Short molding cycle (20-25 minutes/piece), 10 times faster than traditional concrete curing

- Mold life is more than 100,000 times, suitable for large-scale production

- Support multi-cavity mold design, 4-8 pieces can be molded at a time, improving production capacity

Diversified product adaptation

- Standard size: 1000mm/1200mm/1500mm (customizable)

- Surface texture options: imitation stone, wood grain, glossy, anti-slip texture, etc.

Environmental protection and energy saving

- BMC materials are recyclable and in line with the trend of green buildings

- Compared with concrete, 60% carbon emissions are reduced

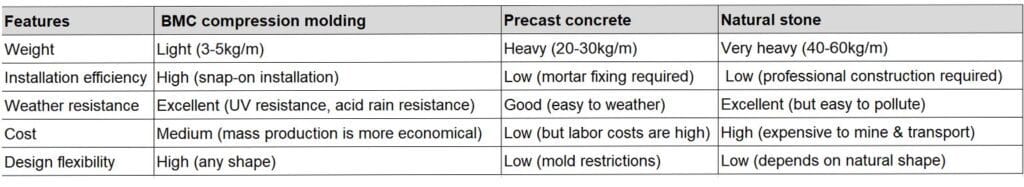

BMC wall cap VS traditional material comparison

Conclusion: BMC wall pressure top surpasses traditional solutions in terms of lightweight, easy installation, weather resistance and design freedom, and is especially suitable for high-end residential, municipal engineering, industrial parks and other scenarios.

Successful Cases & Market Applications

Municipal Engineering: Upgrading a City Landscape Fence

- Requirement: Replace old concrete capping and improve weathering resistance

- Solution: Use BMC imitation stone texture capping to increase installation efficiency by 50%

- Effect: No cracking or fading in 3 years, and maintenance costs are reduced by 70%

High-end Residence: Integrated design of villa area fence

- Requirement: Customized arc capping to match modern architectural style

- Solution: Develop exclusive molds to achieve seamless splicing

- Effect: Owner satisfaction is 100%, and the project won the architectural design award

Industrial Park: Corrosion-resistant fence system

- Requirement: Acid and alkali corrosion-resistant fence solution for chemical parks

Solution: BMC+special coating, improved chemical corrosion resistance - Effect: Service life extended to more than 15 years

Why choose our BMC fence top mold?

✅ Rich experience: 10+ years of experience in composite mold R&D

✅ Customized service: support OEM/ODM, fast proofing (7-15 days)

✅ Global supply: exported to Europe, America, the Middle East, and Southeast Asia

✅ Technical support: provide full process guidance from mold development to mass production

Looking to the future: Innovative applications of BMC in the construction field

With the popularization of green buildings and prefabricated buildings, BMC molding technology will shine in more fields, including:

- Architectural decorative lines

- Outdoor furniture (bench, flower box, etc.)

- Railway protection components

- Solar frames & brackets

WS MOLD will continue to invest in research and development to promote the in-depth application of BMC technology in the construction industry.

Contact us for a customized solution!

If you are looking for a high-performance, low-cost, fast-delivery wall capping solution, please consult our engineering team!

📞 Tel: +86 13456489912

📧 Email: sophie@wsmcmold.com

🌐 Website: www.wsmcmold.com