In the realm of modern industrial manufacturing, the demand for durable, lightweight, and versatile materials has never been higher. One such material that has gained significant traction is Fiberglass Reinforced Plastic (FRP). This blog delves into the world of FRP panel mould manufacturing, focusing on compression molding fiberglass flat plate molds, and explores the intricacies of producing these essential components.

Table of Contents

ToggleUnderstanding Fiberglass Reinforced Plastic (FRP)

FRP is a composite material made from a plastic matrix reinforced with fine fibers of glass. The combination of these two materials results in a product that is not only strong and lightweight but also highly resistant to corrosion, making it ideal for a wide range of applications. From construction to automotive, marine, and even aerospace industries, FRP has proven its worth time and again.

The process of creating FRP involves several steps. First, the glass fibers are woven into a fabric or mat. This fabric is then impregnated with a resin, which acts as the binding agent. The resin and fiber combination is then molded into the desired shape and cured, resulting in a rigid, durable panel. The versatility of FRP lies in its ability to be molded into various shapes and sizes, making it suitable for creating flat plates as well as more complex structures.

When it comes to construction, FRP panel molds offer significant benefits. FRP stands for “fiberglass reinforced plastic,” which means these molds are not only durable but also designed for longevity. They can be reused multiple times without compromising quality. WS’s FRP panels Molds are engineered to endure the tough conditions often found on construction sites. This makes them an ideal choice for builders looking for reliable and cost-effective solutions.

The Role of Fiberglass Flat Plate Molds

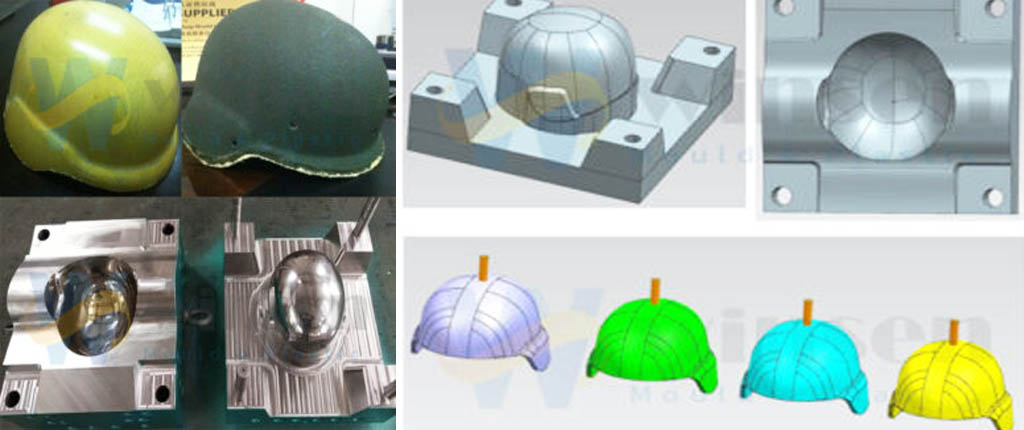

Fiberglass flat plate molds are crucial in the production of FRP panels. These compression molds serve as the foundation upon which the FRP panels are formed. The quality and precision of the mold directly impact the final product’s integrity and performance.

Precision Engineering

Creating a fiberglass flat plate mold requires meticulous precision. The mold must be designed to exact specifications to ensure that the resulting FRP panel meets the required dimensions and tolerances. Advanced engineering techniques and computer-aided design (CAD) software are often employed to create these molds. This allows manufacturers to achieve high levels of accuracy and repeatability in their production processes.

Material Selection

The choice of material for the mold is equally important. Common materials used for fiberglass flat plate molds include steel, aluminum, and even high-grade plastics. Each material has its own set of advantages and disadvantages. For instance, steel molds are highly durable and can withstand repeated use, but they are also heavier and more expensive. Aluminum molds, on the other hand, are lighter and more cost-effective, but may not be as durable as their steel counterparts. The selection of the mold material depends on factors such as the production volume, budget, and specific requirements of the end product.

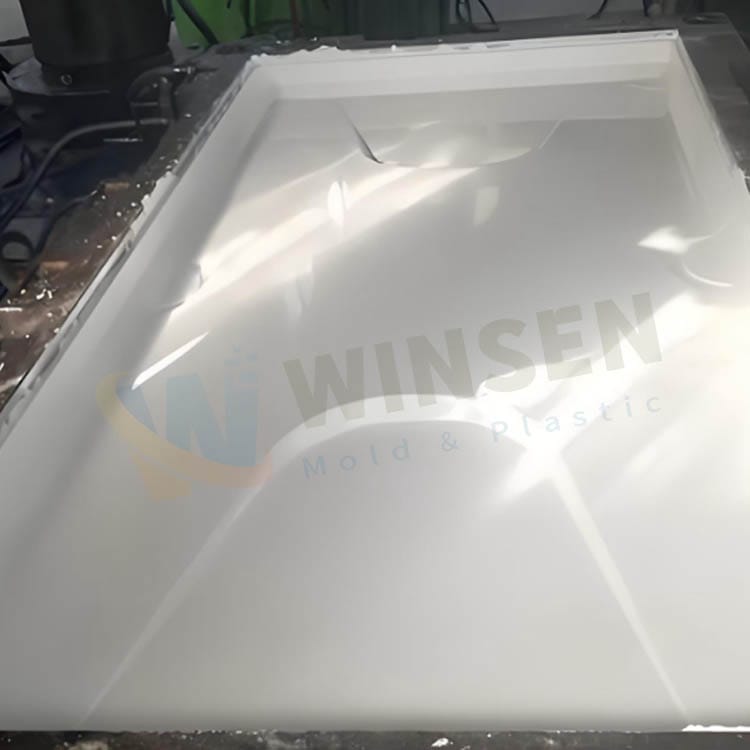

Surface Finish

The surface finish of the mold is another critical factor. A smooth, high-quality surface finish on the mold ensures that the resulting FRP panel has a uniform and defect-free surface. This is particularly important for applications where aesthetics and surface quality are paramount. Techniques such as polishing and coating are often used to enhance the surface finish of the mold.

Manufacturing Process

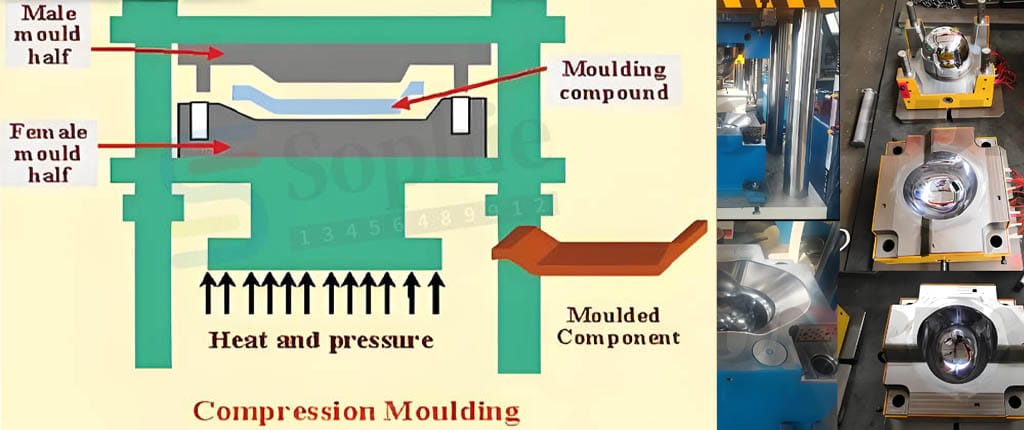

The manufacturing process of FRP panels using fiberglass flat plate molds involves several key steps:

Flat plate Mold Preparation

Before the molding process begins, the compression molds must be thoroughly cleaned and prepared. This ensures that there are no contaminants that could affect the quality of the final product. A release agent is often applied to the mold surface to prevent the FRP material from sticking to the mold during the curing process.

Material Application

The glass fiber fabric or mat is carefully placed into the mold. The resin is then mixed and applied to the fiber material. This mixture is spread evenly across the mold to ensure uniform distribution of the material. The resin acts as the binding agent, holding the glass fibers together and giving the panel its strength and rigidity.

Curing

Once the material is in place, the mold is closed, and the curing process begins. This involves applying heat and pressure to the mold, causing the resin to harden and the panel to take its final shape. The curing process must be carefully controlled to ensure that the panel cures evenly and without defects.

Post-Processing

After the curing process is complete, the mold is opened, and the FRP panel is carefully removed. The panel may then undergo additional post-processing steps such as trimming, drilling, or painting, depending on the specific requirements of the application.

Applications of FRP Panels

The versatility of FRP panels makes them suitable for a wide range of applications. In the construction industry, FRP panels are used for cladding, roofing, and flooring due to their durability and resistance to weather and corrosion. In the automotive sector, FRP panels are used to create lightweight body parts that improve fuel efficiency and reduce emissions. In marine applications, FRP panels are used for boat hulls and decks due to their resistance to water and salt corrosion. The aerospace industry also utilizes FRP panels for aircraft components, taking advantage of their lightweight and high-strength properties.

Choosing the Right Plate Mold Manufacturer

When it comes to selecting a fiberglass flat plate mold FRP panel mould manufacturer, several factors must be considered. The manufacturer’s experience and expertise in the field are crucial. A reputable manufacturer will have a proven track record of producing high-quality molds and panels that meet industry standards. Additionally, the manufacturer’s ability to provide custom solutions tailored to specific requirements is essential. This includes the ability to design and produce molds of various sizes and shapes, as well as the flexibility to work with different materials and finishes.

Another important consideration is the manufacturer’s commitment to quality and sustainability. A good manufacturer will have stringent quality control processes in place to ensure that every mold and panel produced meets the highest standards. They will also be mindful of their environmental impact and strive to implement sustainable practices in their manufacturing processes.

Conclusion

Fiberglass flat plate mold FRP panel mould manufacturing is a complex and highly specialized field. The production of high-quality FRP panels relies on the precision and expertise of the mold manufacturer. By understanding the intricacies of the manufacturing process and selecting the right manufacturer, businesses can ensure that they have access to durable, lightweight, and versatile FRP panels that meet their specific requirements.

As industries continue to evolve and demand more innovative and sustainable solutions, the role of FRP panels and the manufacturers who produce them will only grow in importance. Investing in a reliable and experienced manufacturer is not just a business decision; it is a commitment to quality, durability, and the future of manufacturing.