Injection Mold

A professional injection mold production factory in China, we are a company specializing in the design, manufacturing and supply of plastic injection molds. Over the years, we have been committed to providing high-quality, high-performance injection molds to meet customer needs in a variety of industries. Whether you work in automotive manufacturing, electronic equipment, medical devices, consumer goods manufacturing or other fields, we have the experience and technology to provide you with the best mold solutions.

A plastic injection mold is a tool or mold used to make injection moulding plastic parts or products. It is also known as plastic injection mold, injection mold or plastic mould. This type of mold is used in the injection molding process, where molten plastic material is injected into the mold cavity, where it is then cooled and solidified, ultimately forming a plastic part of the desired shape and size.

Our Hot Sale Plastic Injection Molds

Trust the Experience

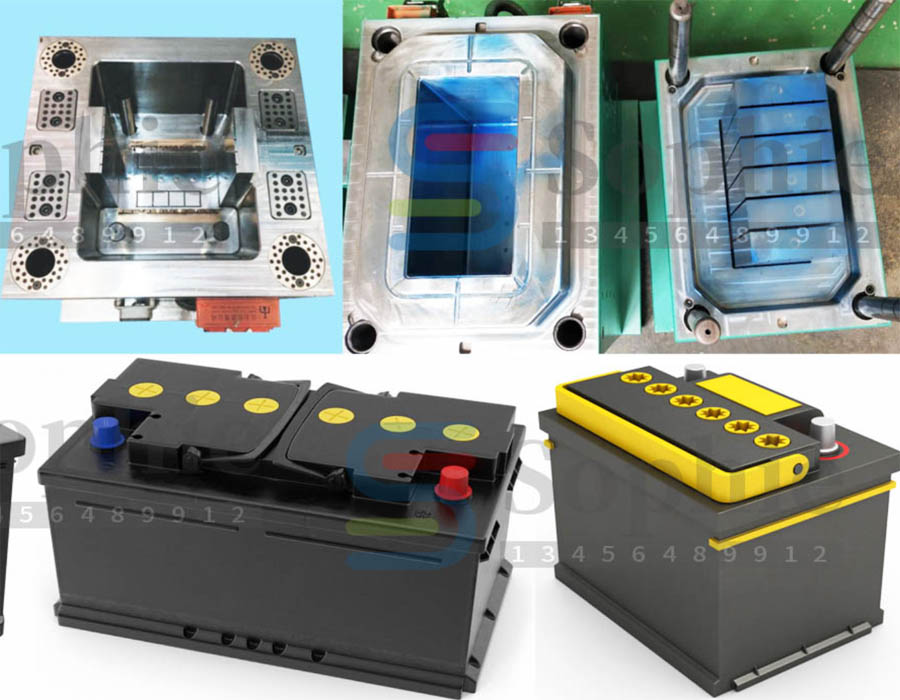

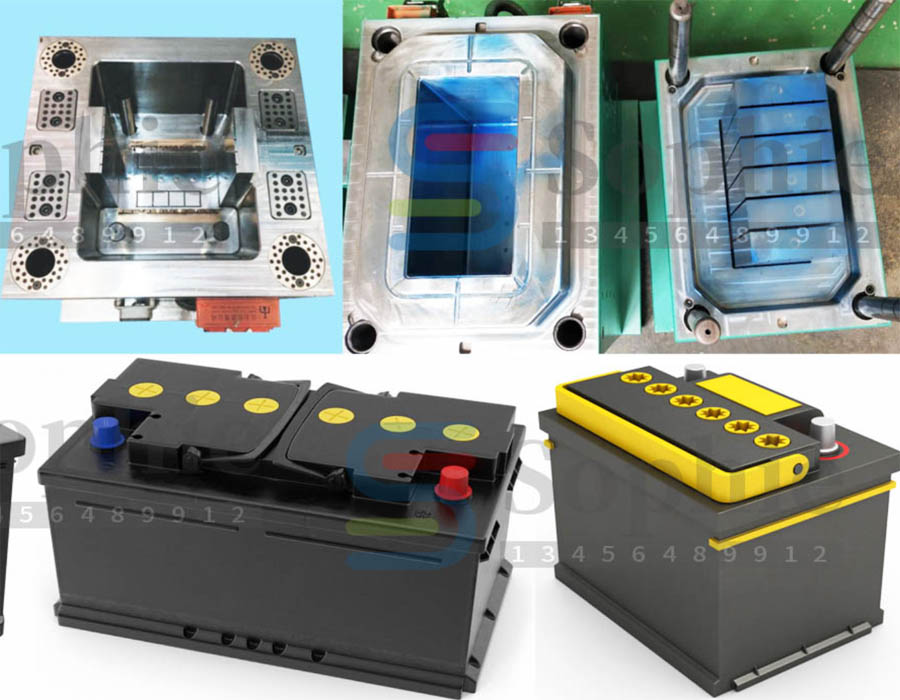

Battery Box Container Mould

Various specifications and models of automotive new energy battery box container molds

Plastic Paint Bucket Moulds

Specializing in the manufacture of packaging molds for paint buckets and chemical barrels

Urine Container Mold

Specializing in manufacturing high quality urine container molds for the medical industry

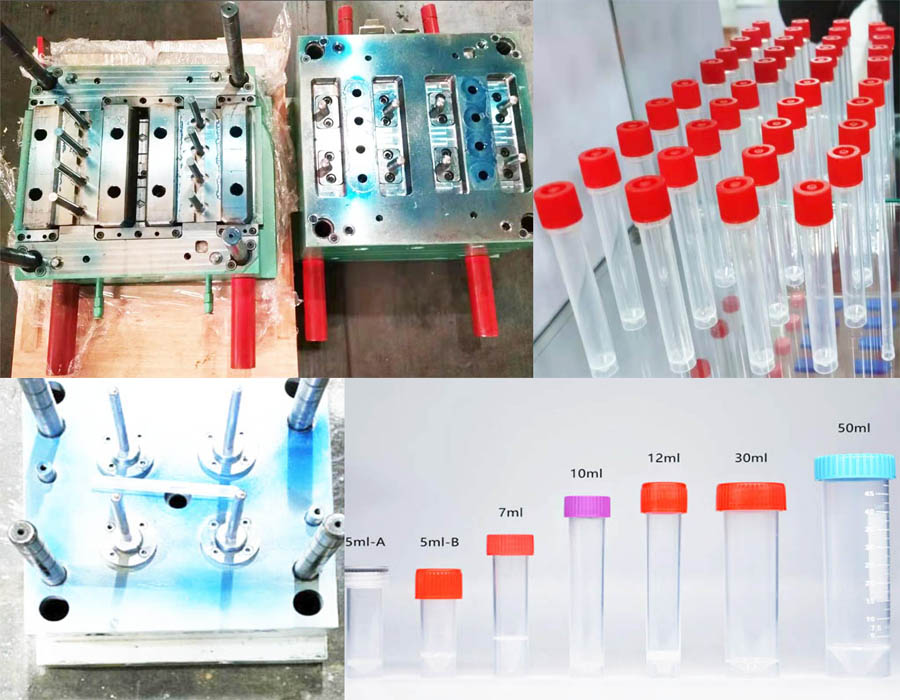

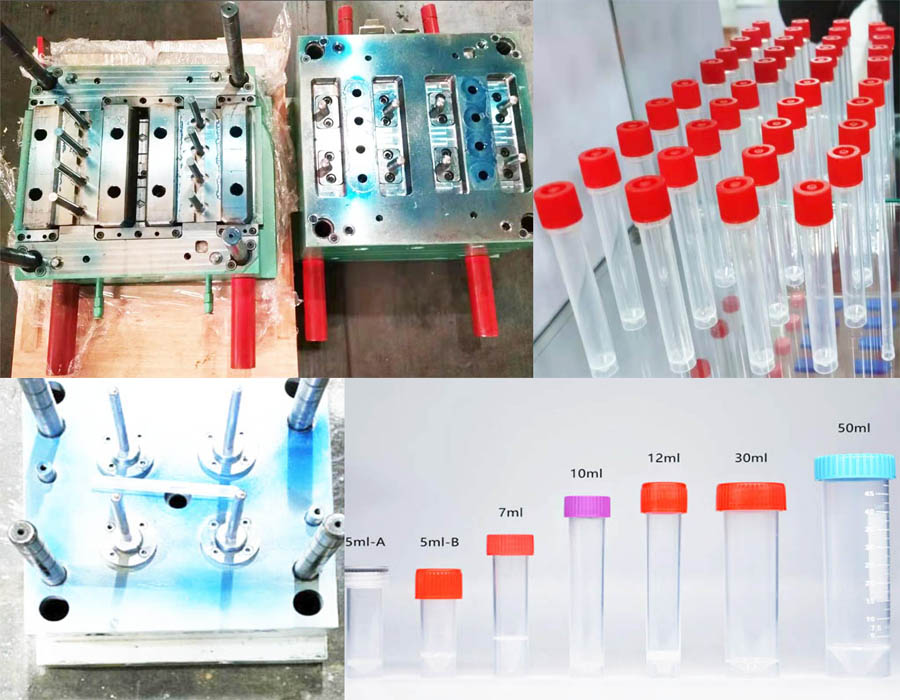

PP PS PET Test Tube Mold

Specializing in manufacturing high quality urine container molds for the medical industry

Helmet Visor Goggles Mold

Making helmet visor mask and goggles molds to assist safety work in different fields

Plastic Juicer blender mould

Precision manufacturing of plastic juicer blender and mixer molds for healthy living

key points about plastic injection molds

Mold Design

Mold Design: The design of plastic injection molds is very critical because it directly affects the quality and accuracy of the final plastic product. A mold usually consists of two main parts: the shape half of the mold and the counter half of the mold. The two parts are separated during the injection molding process to allow easy removal of the final plastic product.

Plastic Injection Molding Process

The injection molding process usually includes the following steps:

- Heating: Plastic pellets or granules are melted and heated to a liquid state.

- Injection: Molten plastic is injected into the mold cavity at high pressure.

- Cooling: The plastic cools and solidifies in the mold, taking the desired shape.

- Open the mold: The mold is opened, allowing the plastic part to be removed.

- Removal: The final plastic part is removed from the mold.

Application Areas

Plastic injection molds are widely used in various industries, including automobile manufacturing, electronics, medical equipment, consumer goods, packaging, etc. From small plastic parts to large casings, plastic injection molds can create plastic products in a variety of shapes and sizes.

Mold Steel Material Selection

The steel material of the plastic injection mold is usually a high-strength, high-wear-resistant metal, such as tool steel or aluminum alloy. These materials can withstand high pressures and temperatures and have a long service life.

Injection Mold Maintenance

To ensure the long-term use of the plastic injection mold, regular maintenance and cleaning is required to prevent wear or damage. Mold maintenance helps maintain the production of high-quality plastic products.

Overall, plastic injection molds are vital tools in the plastic manufacturing process, allowing producers to manufacture a variety of plastic products in an efficient, precise and controlled manner.

Keep improving and innovate endlessly. We are specialized manufacturers of plastic injection molds, committed to providing unparalleled quality and reliability for your creativity and production. Whether you need small or large molds, simple or complex components, we have advanced technology and years of experience to ensure each mold is carefully manufactured to meet your unique needs. Choose us and choose success, because our molds not only create plastics, but also create the future

Manufacturer of plastic injection mold

Scheduling An Appointment

Innovative molds for the future - our plastic injection molds,your successful partner,create precise and reliable molds to help you realize your plastic ideas