Helmet Visor Goggles Mold

Helmet Visor Mold, Face Shield Mold and goggle process

Keep improving, leading the industry

PC Helmet Visor Mold And Goggle Mold Maker

Welcome to our company, where we specialize in manufacturing high-quality Helmet Visor Mold Goggles Mold visor molds for helmet PC lenses and goggles. As a professional lens mold manufacturer, we are committed to providing our customers with the best products and services possible.

Customized design and production of various helmet visor face shield and goggle molds, Motorcycle Electric Vehicle helmet lens mold, sunglasses mold, industrial glasses mold, goggle lens mold, LED optical lens molds, Anti-fog ski goggles Mold, swimming lens molds, precision injection molding optical lens molds, transparent face shield mold, goggles mold, PC lens molds, etc.

Our expertise in this field ensures that we are able to create molds that are precise, durable, and designed to meet the specific needs of our clients. We take pride in our ability to deliver excellent results that exceed expectations, and we look forward to working with you to create custom molds that perfectly match your requirements.sunglasses

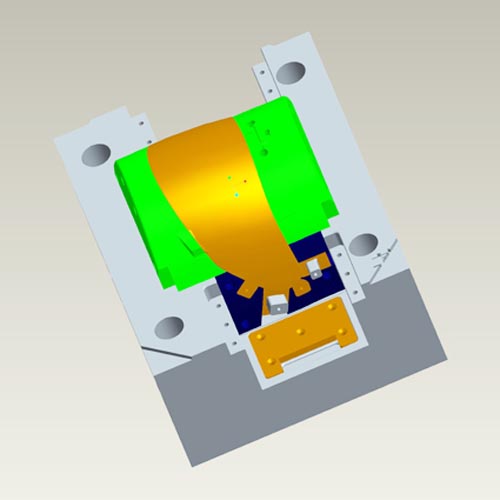

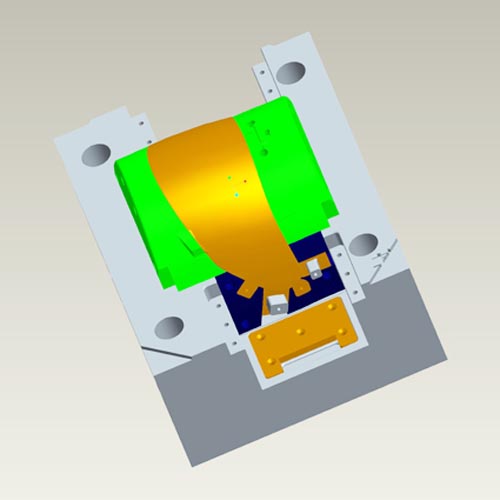

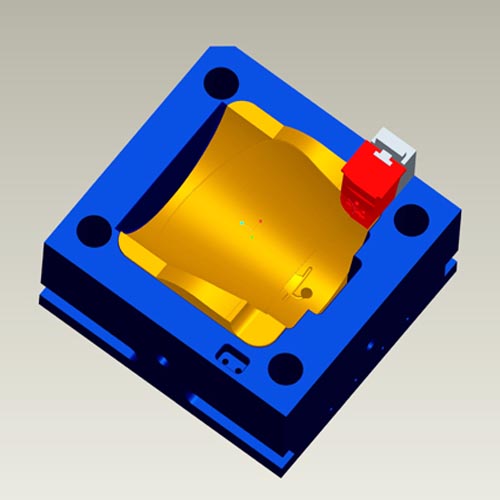

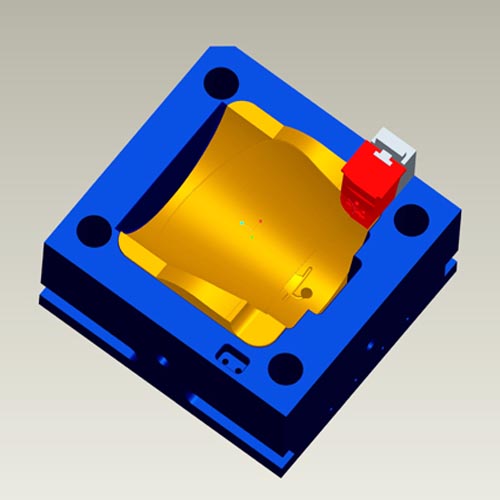

Helmet Visor Mold

PC LED optical helmet lens mold is a specialized tool used for manufacturing high-quality helmet lenses. These lenses are used in a variety of applications, such as motorcycle helmets, military helmets, and sports helmets. They are designed to provide superior protection, visibility, and durability.

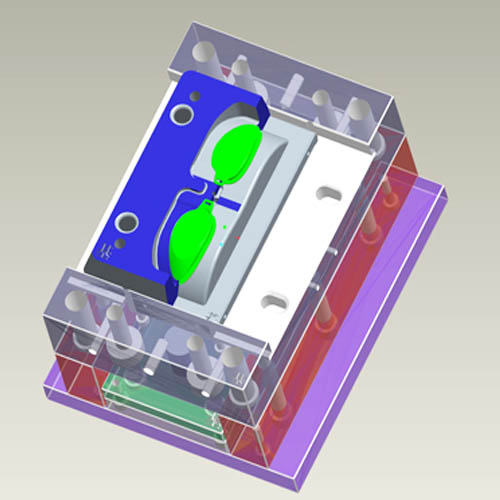

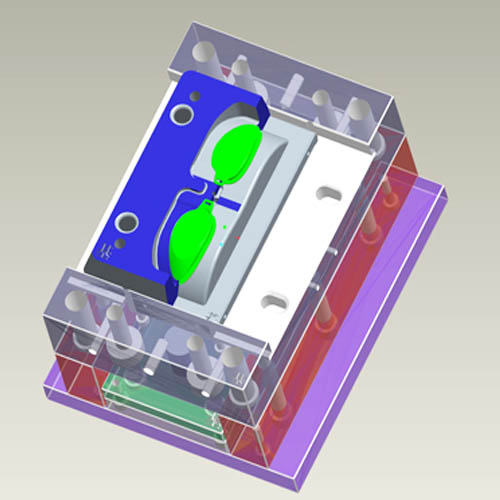

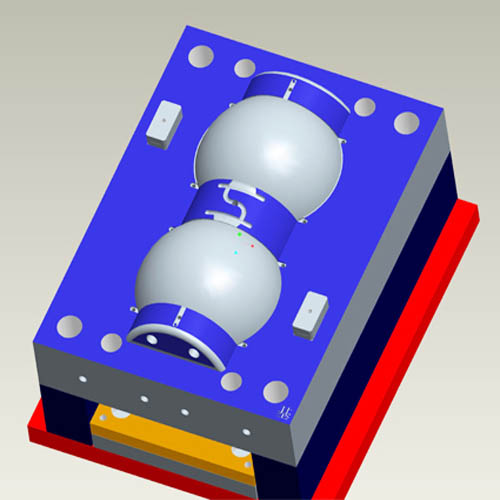

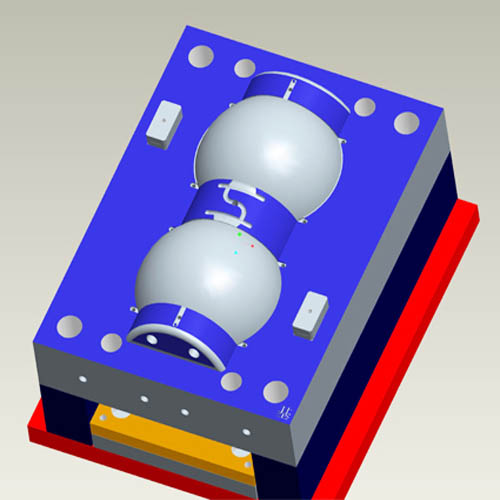

Goggle Lens Mold

Goggle molds are specialized molds used in the manufacturing of goggles or other eyewear that require a curved lens. These molds are typically made from materials such as rubber or plastic . The mold is an essential component in the production of high-quality goggles that provide optimal vision and protection .

Anti-fog Ski Goggles Mold

Anti-fog ski goggles molds are specialized molds used in the manufacturing of ski goggles that are designed to resist fogging. T. The mold is an essential component in the production of high-quality anti-fog ski goggles that provide optimal vision and protection for skiers and snowboarders.

Sunglasses Mold

Sunglasses molds are used in the manufacturing of sunglasses that require a curved lens. We have complete Sunglasses Mold production equipment, fine grinding and polishing equipment and mold design, technical team.

Motorcycle Goggles Mold

Motorcycle goggles mold is a tool used in the manufacturing process of motorcycle goggles. The mold is created by a process called injection molding, which involves injecting molten plastic into the mold under high pressure.

Transparent Face Shield Mold

A transparent face shield mold is a essential tool used for manufacturing high-quality face shields that provide reliable protection for a variety of applications, such as healthcare, industrial, and food service settings.

WS mold have a good experience to make motorcycle electric car helmet visor mold, face shields mold, goggles mold, optical PC lenses mold, ski goggles mold, medical eye lenses mold, and we understands optical principles, and 100% of the lenses have passed European optical testing equipment. Optics can be controlled at 0.02-0.04 is the highest standard. Our factory can do injection molding, strengthening, anti-fog, electroplating and mold development. The factory is well-equipped, the source manufacturer.we have been committed to the design and manufacture of precision plastic injection PC transparent product molds.

Plastic Injection Helmet Visor Mold Face Shield Mold

Plastic Goggle Injection Mold

Contact Us Now For Your Plastic Injection Helmet Visor Mold Goggles Mold Solution

Find the reliable supplier for your Helmet Visor Goggles Mold , we can suply molds for all kinds of precision helmet visor goggles products mold design and manufacturing,The plastic injection motorcycle visor face shield mould custom production with export high quality

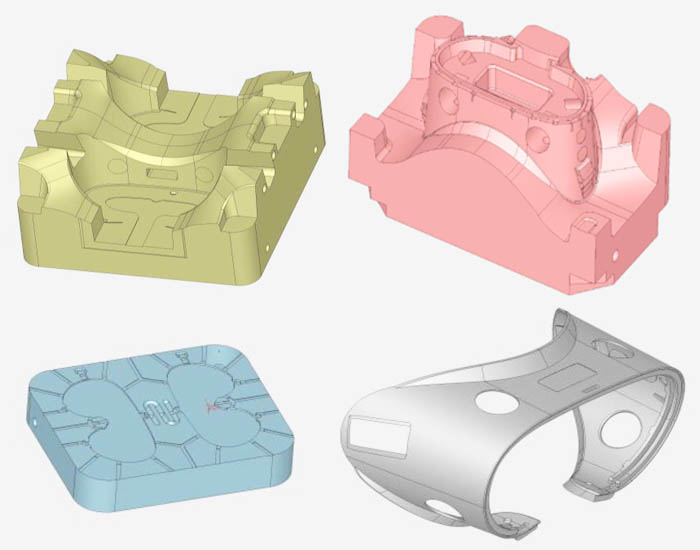

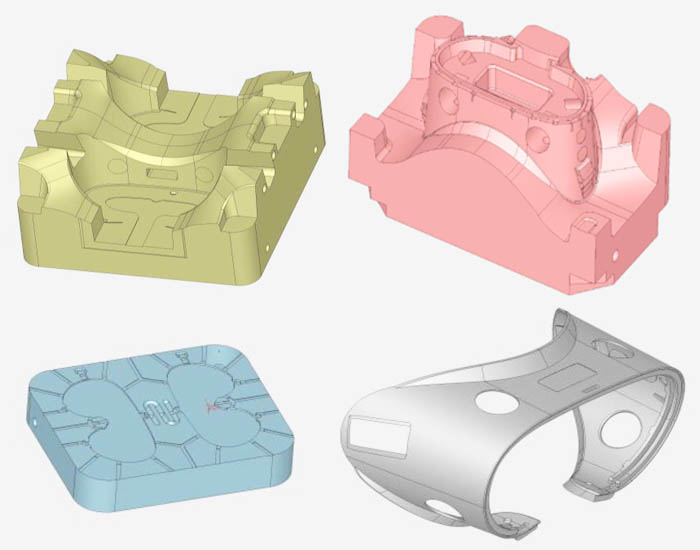

Helmet Visor Mold Goggles Mold Design

Swimming Goggle Lens Mold

Helmet Lens Mold

Helmet shield Lens Mold

Labor protection spectacle lens mold

Aspherical lens mold

Plastic Aspheric Lens Injection Mold

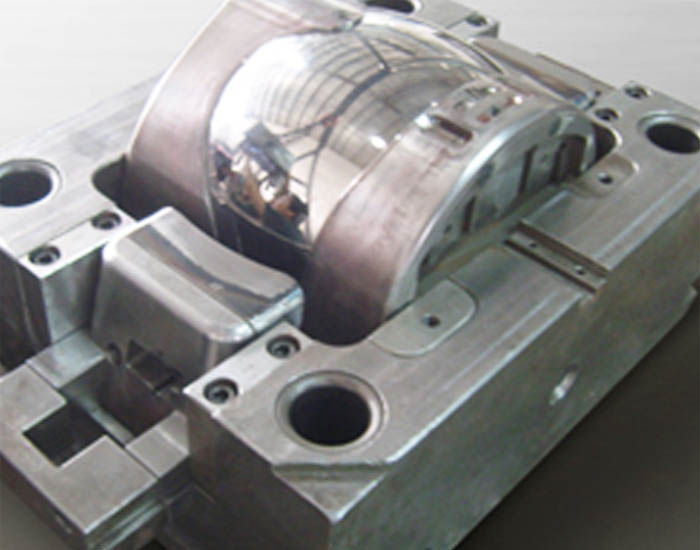

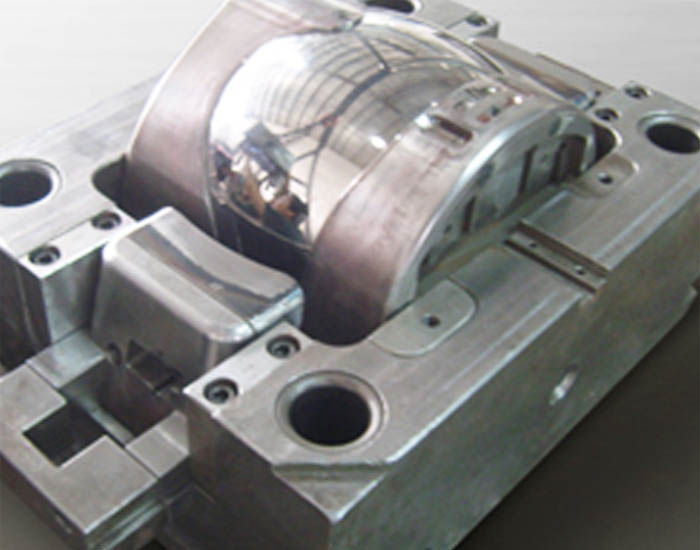

Helmet Visor Mold Goggles Mold Details

Mold steel: high-quality mirror steel is used for fine workmanship, Longji, ASSAB S136,NAK80,45# quenched and tempered 60# quenched and tempered P20H,718H,2316 for your choice;

Mold Base: DME, HASCO, FUTABA, LKM;

Cooling system: optimized design of circulating water, improve production efficiency and reduce your cost;

Mid-term treatment: quenching and tempering, improving hardness;

Post-processing: vacuum heat treatment, nitriding;

Mold life: The normal use of P20 is not less than 300,000 mold times, and the normal use of S136 is more than 1 million mold times.

Mold acceptance and delivery:

★Submit the mold according to the negotiated delivery date;

★The mold size determined by the customer;

★The technical process plan confirmed by the customer;

★Mold design drawings and electronic documents;

★According to customer requirements, the debugging reaches the product assembly qualification, and can be formally produced;

★The product sample reaches the surface without deformation, shrinkage, injection holes and other defects that affect vision, and passes the optical test standard specified by the customer.

Helmet Visor Mold Goggles Mold processing technology: The purpose of the hardening process is to cause structural transformation of steel. First, the ferritic material structure is transformed into austenite by heating, and then transformed into martensite with high hardness by quenching. The absolute advantage of laser hardening is that it can optionally

Industrial Safety Protective Glasses Lens Mold

Motorcycle Optical Lens Mold

Optical lens mold products wear dizziness, the main reason

1. The mold design does not adjust the optical surface;

2. Polishers are not professional optical polishers;

3. The hardness of the mold material is not enough, and the density is not enough, resulting in poor optics.

Our factory undertakes custom-made lens molds, mold maintenance, optical polishing, and optical surface adjustment design.

This product is an optical helmet lens visor. The front and rear molds must be CNC processed at high speed to ensure the surface roughness of the mold is matte. Mold material Sweden S136 vacuum heat treatment. Guaranteed to pass European optical testing standards.

Precise prescription glasses mold processing, this mold has extremely high requirements, if there is a deviation, it will affect myopia, the mold material S136 is hardened and heat-treated with an allowance of 0.3 for semi-finishing and then finishing. The positive and negative tolerance is within 0.003.

Optical mirror plate polishing jig mold, medical polishing jig, plus or minus tolerance within 0.005mm.

All kinds of protective glasses molds, labor protective industrial glasses & lens molds, customized production of industrial safety protective glasses lens molds, welcome to contact.